DTPL

Bulk Data Entry Defines parameters for the generation of topology design variables.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DTPL | ID | PTYPE | PID1 | PID2 | PID3 | PID4 | PID5 | PID6 | |

| PID7 | etc | etc | etc | etc | etc | etc | |||

| etc | etc |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| TMIN | T0 |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| STRESS | UBOUND |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MEMBSIZ | MINDIM | MAXDIM | MINGAP |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MESH | MTYP |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DRAW | DTYP | DAID/XDA | YDA | ZDA | DFID/XDF | YDF | ZDF | ||

| OBST | OPID1 | OPID2 | OPID3 | OPID4 | OPID5 | OPID6 | OPID7 | ||

| OPID8 | etc | etc | etc | etc | etc | etc | |||

| NOHOLE | |||||||||

| STAMP | TSTAMP |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| EXTR | ETYP | ||||||||

| EPATH1 | EP1_ID1 | EP1_ID2 | EP1_ID3 | EP1_ID4 | EP1_ID5 | EP1_ID6 | EP1_ID7 | ||

| EP1_ID8 | etc | etc | etc | etc | etc | etc | |||

| etc | etc | ||||||||

| EPATH2 | EP2_ID1 | EP2_ID2 | EP2_ID3 | EP2_ID4 | EP2_ID5 | EP2_ID6 | EP2_ID7 | ||

| EP2_ID8 | etc | etc | etc | etc | etc | etc | |||

| etc | etc |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MAIN | |||||||||

| COORD | CID | CAID/ XCA |

YCA | ZCA | CFID/ XCF |

YCF | ZCF | ||

| CSID/ XCS |

YCS | ZCS | CTID/ XCT |

YCT | ZCT |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| SECOND | DTPL_ID | ||||||||

| COORD | CID | CAID/ XCA |

YCA | ZCA | CFID/ XCF |

YCF | ZCF | ||

| CSID/ XCS |

YCS | ZCS | CTID/ XCT |

YCT | ZCT |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| COORD | CID | CAID/

XCA |

YCA | ZCA | CFID/ XCF |

YCF | ZCF | ||

| CSID/ XCS |

YCS | ZCS | CFTID/ XCT |

YCT | ZCT |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| SCALE | SX | SY | SZ |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MATINIT | VALUE |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| PATRN | TYP | AID/ XA |

YA | ZA | FID/ XF |

YF | ZF | ||

| UCYC | SID/ XS |

YS | ZS |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MAT | MATOPT |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| FATIGUE | FTYPE | FBOUND |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| LEVELSET | HOLEINST | HOLERAD | NHOLESX | NHOLESY | NHOLESZ |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| LATTICE | LT | LB | UB | LATSTR |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| FAILSAFE | SFAIL | DFAIL | TFAIL | DFAIL | PFAIL |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MMAT | MID1 | MID2 | MID3 | MID4 | MID5 | MID6 | MID7 | ||

| MID8 | MID9 |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| OVERHANG | ANGLE | GID1/ X1 |

Y1 | Z1 | GID2/ X2 |

Y2 | Z2 | ||

| METHOD | STEP/ PENFAC |

PENSCHE | NONDES | HOLES | ANGTOL | DISTOL | |||

| SUPPSET |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MILL | ANGLE / R | B | H | ||||||

| OBST | OPID1 | OPID2 | OPID3 | OPID4 | OPID5 | OPID6 | OPID7 | ||

| OPID8 | etc. | etc. | etc. | etc. | etc. |

Example 1

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DTPL | 1 | PSHELL | 7 | 8 | 17 | ||||

| MEMBSIZ | 60.0 | ||||||||

| TMIN | 1.0 |

Example 2

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DTPL | 1 | PSOLID | 4 | 5 | 6 | ||||

| MEMBSIZ | 60.0 | ||||||||

| DRAW | SPLIT | 0.0 | 0.0 | 0.0 | 1.0 | 0.0 | 0.0 | ||

| OBST | 10 | 11 | 12 |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| ID | Each

DTPL Bulk Data Entry must have a unique

ID. No default (Integer > 0) |

|

| PTYPE | Flag for the property

type, laminate, or element set that defines

DTPL.

No default |

|

| PID# | Property, laminate

(STACK), or element SET identification numbers that define

DTPL. If PIDs are not listed, OptiStruct will check all properties or laminates of type PTYPE to see if they are to be included in the design space (see PCOMP, PSHELL, PSOLID, STACK, and so on). If any properties satisfy this search, then they will be affected by entries on this card. In this situation (where PIDs are not defined), only one DTPL card can be defined for the given PTYPE. Refer to 26 for limitations when PTYPE=SET. Default = blank (Integer > 0 or blank) |

|

| TMIN | Indicates that minimum

thickness value will follow. Only valid when

PTYPE=PSHELL. If not present when PTYPE=PSHELL, the minimum thickness will default to the T0 value defined on the PSHELL card. If a T0 value is not defined on the PSHELL card, the minimum thickness will default to 0.0. |

|

| T0 | Minimum thickness for

PSHELL properties when the referenced

material is of type MAT1. If PSHELL references a material which is not of type MAT1, this value is ignored and T0=0.0 is used. If a value is not entered for T0, the T0 value on the PSHELL card is used. If T0 is not defined on the PSHELL card, then T0=0.0 is assumed. Default = blank (Real > 0.0) |

|

| STRESS | Indicates that stress constraints are active and that an upper bound value for stress is to follow. 1 | |

| UBOUND | Upper bound constraint on

stress. No default (Real > 0.0) |

|

| MEMBSIZ | Indicates that member size control is active for the properties listed and if MINDIM and possibly MAXDIM are to follow. | |

| MINDIM | Specifies the minimum

diameter of members formed. This command is used to eliminate small

members. It also eliminates checkerboard results. 2

Default = No Minimum Member Size Control (Real > 0.0) |

|

| MAXDIM | Specifies the maximum

diameter of members formed. This command is used to prevent the

formation of large members. Only used in combination with

MINDIM. This is supported for both

traditional Density method (SIMP) and Level Set methods. 3 Default = No Maximum Member Size Control (Real > 0.0) |

|

| MINGAP | Defines the minimum

spacing between structural members formed. Only used in conjunction

with MAXDIM. This is supported for both

traditional Density method (SIMP) and Level Set methods. 3 Default = blank (Real > MAXDIM for SIMP method and Real < MAXDIM for Level Set method) |

|

| MESH | Indicates that mesh type information is to follow. | |

| MTYP | Indicates that the mesh

conforms to certain rules for which the optimizer is tuned.

Currently, the only option available is ALIGN,

which indicates when manufacturing constraints are active, the mesh

is aligned with the draw direction or extrusion path. 4 Default = blank (ALIGN or blank) |

|

| DRAW | Indicates that casting

constraints are being applied and that draw direction information is

to follow. Only valid if PTYPE=PSOLID. OptiStruct will terminate with an error, if present for other PTYPEs. |

|

| DTYP | Draw direction constraint

type to be used.

|

|

| DAID/XDA, YDA, ZDA | Draw direction anchor

point. These fields define the anchor point for draw direction of

the casting. The point may be defined by entering a grid ID in the

DAID field or by entering X, Y, and Z

coordinates in the XDA, YDA,

and ZDA fields, these coordinates will be in the

basic coordinate system. Default = origin (Real in all three fields or Integer in first field) |

|

| DFID/XDF, YDF, ZDF | Direction of vector for

draw direction definition. These fields define a point. The vector

goes from the anchor point to this point. The point may be defined

by entering a grid ID in the DFID field or by

entering X, Y, and Z coordinates in the XDF,

YDF, and ZDF fields, these

coordinates will be in the basic coordinate system. No default (Real in all three fields or Integer in first field) |

|

| OBST | Indicates that a list of

PIDs will follow which are non-designable,

but their interaction with designable parts needs to be considered

with regards to the defined draw direction. OBST

stands for obstacle. Only recognized if DRAW flag is also present on the same DTPL card. OptiStruct will terminate with an error, if OBST flag is present without DRAW flag. |

|

| OPID# | Obstacle property

identification number. List of non-designable properties that are to

be considered with regards to the defined draw direction. These must

be PSOLID. No default (Integer > 0, blank or ALL) |

|

| NOHOLE | Prevents the formation of

through-holes in the draw direction. Note: It does not prevent holes

perpendicular to the draw direction. The assumed minimum

thickness in the draw direction is twice the average mesh

size. |

|

| STAMP | Forcing the design to evolve into a 3D shell structure. Indicates that thickness (TSTAMP) is to follow. 5 | |

| TSTAMP | Defines the thickness of

the 3D shell structure that is evolved with the

STAMP option. The recommended minimum thickness

is three times the average mesh size. 5 No default (Real > 0.0) |

|

| EXTR | Indicates that extrusion

constraints are being applied and that extrusion information is to

follow. Only valid if PTYPE=PSOLID. OptiStruct will terminate with an error, if present for other PTYPEs. |

|

| ETYP | Extrusion constraint type

to be used.

|

|

| EPATH1 | Indicates that a list of

grid IDs will follow to define the primary extrusion path. Only recognized if EXTR flag is also present on the same DTPL card. OptiStruct will terminate with an error, if EPATH1 flag is present without EXTR flag. |

|

| EP1_ID# | Primary extrusion path

identification numbers. List of grid IDs that define the primary

extrusion path. No default (Integer > 0 or blank) |

|

| EPATH2 | Indicates that a list of

grid IDs will follow to define the secondary extrusion path. This is

only required when ETYP has been set to

TWIST. Only recognized if EXTR flag is present on the same DTPL card. OptiStruct will terminate with an error, if EPATH2 flag is present without EXTR flag. |

|

| EP2_ID# | Secondary extrusion path

identification numbers. List of grid IDs that define the secondary

extrusion path. No default (Integer > 0 or blank) |

|

| MAIN | Indicates that this design variable may be used as a main pattern for pattern repetition. 7 | |

| COORD | Indicates information regarding the coordinate system for pattern repetition is to follow. This is required if either MAIN or SECOND flag is present. | |

| CID | Coordinate system ID for a

rectangular coordinate system that may be used as the pattern

repetition coordinate system. 7 Default = 0 (Integer ≥ 0) |

|

| CAID/XCA, YCA, ZCA | Anchor point for pattern

repetition coordinate system. The point may be defined by entering a

grid ID in the CAID field or by entering X, Y,

and Z coordinates in the XCA,

YCA, and ZCA fields. These

coordinates will be in the basic coordinate system. 7 No default (Real in all three fields or Integer in first field) |

|

| CFID/XCF, YCF, ZCF | First point for pattern

repetition coordinate system. The point may be defined by entering a

grid ID in the CFID field or by entering X, Y,

and Z coordinates in the XCF,

YCF, and ZCF fields. These

coordinates will be in the basic coordinate system. 7 No default (Real in all three fields or Integer in first field) |

|

| CSID/XCS, YCS, ZCS | Second point for pattern

repetition coordinate system. The point may be defined by entering a

grid ID in the CSID field or by entering X, Y,

and Z coordinates in the XCS,

YCS, and ZCS fields. These

coordinates will be in the basic coordinate system. 7 No default (Real in all three fields or Integer in first field) |

|

| CTID/XCT, YCT, ZCT | Third point for pattern

repetition coordinate system. The point may be defined by entering a

grid ID in the CTID field or by entering X, Y,

and Z coordinates in the XCT,

YCT, and ZCT fields. These

coordinates will be in the basic coordinate system. 7 No default (Real in all three fields or Integer in first field) |

|

| SECOND | Indicates that this design variable is secondary to the main pattern definition referenced by the following DTPL_ID entry. 7 | |

| DTPL_ID | DTPL

identification number for a main pattern definition. No default (Integer > 0) |

|

| COORD | Indicates information regarding the coordinate system for pattern repetition is to follow. This is required if either MAIN or SECOND flag is present. | |

| CID | Coordinate system ID for a

rectangular coordinate system that may be used as the pattern

repetition coordinate system. 7. Default = 0 (Integer > 0) |

|

| CAID/XCA, YCA, ZCA | Anchor point for pattern

repetition coordinate system. The point may be defined by entering a

grid ID in the CAID field or by entering X, Y,

and Z coordinates in the XCA,

YCA, and ZCA fields. These

coordinates will be in the basic coordinate system. 7 No default (Real in all three fields or Integer in first field) |

|

| CFID/XCF, YCF, ZCF | First point for pattern

repetition coordinate system. The point may be defined by entering a

grid ID in the CFID field or by entering X, Y,

and Z coordinates in the XCF,

YCF, and ZCF fields. These

coordinates will be in the basic coordinate system. 7 No default (Real in all three fields or Integer in first field) |

|

| CSID/XCS, YCS, ZCS | Second point for pattern

repetition coordinate system. The point may be defined by entering a

grid ID in the CSID field or by entering X, Y,

and Z coordinates in the XCS,

YCS, and ZCS fields. These

coordinates will be in the basic coordinate system. 7 No default (Real in all three fields or Integer in first field) |

|

| CTID/XCT, YCT, ZCT | Third point for pattern

repetition coordinate system. The point may be defined by entering a

grid ID in the CTID field or by entering X, Y,

and Z coordinates in the XCT,

YCT, and ZCT fields. These

coordinates will be in the basic coordinate system. 7 No default (Real in all three fields or Integer in first field) |

|

| SCALE | This is applicable to

Pattern Repetition and Multi-Model Optimization (MMO)

functionalities. Indicates that scaling factors for pattern repetition (Main-Secondary) in a model or for Multi-Model Optimization (across multiple models) is active. |

|

| SX, SY, SZ | Scale factors for pattern

repetition or Multi-Model Optimization in X, Y, and Z directions,

respectively. 7 Default = 1.0 (Real) |

|

| COORD | Indicates information regarding the coordinate system for Multi-Model Optimization is to follow. This is required for Multi-Model Optimization runs (unless individual pattern repetition within each model is active using MAIN/SECOND continuation lines). | |

| CAID/XCA, YCA, ZCA | Anchor point for

coordinate system used in Multi-Model Optimization. The point may be

defined by entering a grid ID in the CAID field

or by entering X, Y, and Z coordinates in the

XCA, YCA, and

ZCA fields. These coordinates will be in the

basic coordinate system. 13 No default (Real in all three fields or Integer in first field) |

|

| CFID/XCF, YCF, ZCF | First point for coordinate

system used in Multi-Model Optimization. The point may be defined by

entering a grid ID in the CFID field or by

entering X, Y, and Z coordinates in the XCF,

YCF, and ZCF fields. These

coordinates will be in the basic coordinate system. 13 No default (Real in all three fields or Integer in first field) |

|

| CSID/XCS, YCS, ZCS | Second point for

coordinate system used in Multi-Model Optimization. The point may be

defined by entering a grid ID in the CSID field

or by entering X, Y, and Z coordinates in the

XCS, YCS, and

ZCS fields. These coordinates will be in the

basic coordinate system. 13 No default (Real in all three fields or Integer in first field) |

|

| CTID/XCT, YCT, ZCT | Third point for coordinate

system used in Multi-Model Optimization. The point may be defined by

entering a grid ID in the CTID field or by

entering X, Y, and Z coordinates in the XCT,

YCT, and ZCT fields. These

coordinates will be in the basic coordinate system. 13 No default (Real in all three fields or Integer in first field) |

|

| PATRN | Indicates that pattern

grouping is active for the properties listed and that information

for pattern grouping is to follow. Pattern grouping is supported for all entries listed in the PTYPE field except for PBUSH and PWELD. 8, 9 |

|

| TYP | Indicates the type of

pattern grouping requested. 9 Default = No Pattern Grouping (1, 2, 3, 9, 10, or 11) |

|

| AID/XA, YA, ZA | Anchor point for pattern

grouping. The point may be defined by entering a grid ID in the

AID field or by entering X, Y, and Z

coordinates in the XA, YA, and

ZA fields. These coordinates will be in the

basic coordinate system. 9 Default = origin (Real in all three fields or Integer in first field) |

|

| FID/XF, YF, ZF | First point for pattern

grouping. The point may be defined by entering a grid ID in the

FID field or by entering X, Y, and Z

coordinates in the XF, YF, and

ZF fields. These coordinates will be in the

basic coordinate system. 9 No default (Real in all three fields or Integer in first field) |

|

| UCYC | Number of cyclical

repetitions for cyclical symmetry. This field defines the number of

radial "wedges" for cyclical symmetry. The angle of each wedge is

computed as 360.0/UCYC. 9 Default = blank (Integer > 0 or blank) |

|

| SID/XS, YS, ZS | Second point for pattern

grouping. The point may be defined by entering a grid ID in the

SID field or by entering X, Y, and Z

coordinates in the XS, YS, and

ZS fields. These coordinates will be in the

basic coordinate system. 9 No default (Real in all three fields or Integer in first field) |

|

| MATINIT | Continuation line to define the DTPL-dependent initial material fraction. | |

| VALUE | Default = 0.9 for

optimization with mass as the objective, Default is reset to the

constraint value for runs with constrained mass. If mass is not the

objective function and is not constrained, then the default is

0.6.

This continuation line takes precedence over DOPTPRM,MATINIT for this design variable. |

|

| MAT | Indicates the type of composite topology optimization. Only considered for PTYPE=PCOMP. | |

| MATOPT |

|

|

| FATIGUE | Indicates that fatigue constraints are active and their definitions are to follow. | |

| FTYPE | Fatigue constraint

type.

|

|

| FBOUND | Specifies the bound

value. If FTYPE=DAMAGE, FBOUND will be the upper bound of fatigue damage. If FTYPE=LIFE or FOS, FBOUND will be the lower bound of fatigue life (LIFE) or Factor of Safety (FOS), respectively. No default (Real) |

|

| LEVELSET | Indicates that the Level Set method (for topology optimization) is activated and the definitions of the required parameters follow. 21 - 24 | |

| HOLEINST | Method used to insert holes into the design.

|

|

| HOLERAD | <REAL NUMBER> A real

number that specifies the initial radius of the holes.

Default = 5 times the average mesh size |

|

| NHOLESX / NHOLESY / NHOLESZ | <POSITIVE INTEGER> A

positive integer that specifies the number of holes in X

direction (when HOLEINST=

ALIGN).

NHOLESY and NHOLESZ can be inferred by analogy. |

|

| LATTICE | Indicates that Lattice Structure Optimization is activated and the definitions of the required parameters are to follow. | |

| LT | Lattice type (only

applicable to hexahedral elements). For other element types

(tetrahedron, pyramid, and pentahedron), there is only one lattice

type and it is active by default. 10

11 Default = 1 (Integer: 1, 2, 3, or 4) |

|

| LB | Density lower bound. 10

11 Default = 0.1 (0.0 ≤ Real ≤ 1.0) |

|

| UB | Density upper bound. 10

11 Default = 0.8 (0.0 ≤ Real ≤ 1.0) |

|

| LATSTR | Stress constraint for

Phase 2 of Lattice Optimization (see Stress Constraints in the User Guide). No default (Real) |

|

| FAILSAFE | Indicates that Failsafe Topology Optimization is activated and the definitions of the required parameters are to follow. 12 | |

| SFAIL | Size of the individual

Failure Zones in a particular layer. This is the edge length for

CUBE failure zone (see

TFAIL) and the diameter for

SPHERE. No default (Real > 0.0) |

|

| DFAIL | Distance (spacing) between

Failure Zones in a particular layer. This is the distance between

the center of one failure zone to the next. Default = SFAIL (Real > 0.0) |

|

| TFAIL | Failure Zone type.

|

|

| OFAIL | Activates the Overlap

(second) Failure Zone in addition to the first Failure zone.

|

|

| PFAIL | Defines the ratio

(fraction) of total design volume below which the volume is not

considered as a Damage Zone. Default = 0.0 (Real > 0.0) |

|

| MMAT | Indicates that Multiple Materials Topology Optimization is activated and the definitions of the required parameters are to follow. 14 | |

| MAT# | Candidate material

identification numbers. List of candidate materials used for

multiple material optimization. 15 No default (Integer > 0 or blank) |

|

| OVERHANG | Indicates that Overhang Constraints are active and the definitions of the required parameters are to follow. | |

| ANGLE | Orientation angle for the

Overhang Constraint. This angle is measured from the build

direction, and a larger angle implies more design freedom. No default (Real ≥ 0.0) |

|

| GID1, GID2 | Grid point identification

numbers which identify the orientation. The orientation can also be

identified by defining coordinates (X#,

Y#, Z#). Default = Blank (Integer > 0) |

|

| X#, Y#, Z# | Coordinates of two points

which identifies the orientation. Default = Blank (Real) |

|

| METHOD | Overhang Constraint

Method. 18

|

|

| STEP/ PENFAC |

|

|

| PENSCHE | Penalization scheme. 16

|

|

| NONDES | Indicates the function of

non-design elements.

|

|

| HOLES | Indicates if the holes are

supported or unsupported.

|

|

| ANGTOL | Tolerance angle which

identifies the elements of the design space for which the overhang

constraint is not applied. The identified layer will be assumed as

supported by the optimizer. 19 Default = 90.0 (0.0 ≤ Real ≤ 90.0) Note: For

ANGTOL=90.0, only the first layer of

elements on the surface of the model (encountered when

traveling in the build direction) is

supported. |

|

| DISTOL | Distance which

characterizes the layer of design space for which the overhang

constraint is not applied. The identified layer will be assumed as

supported by the optimizer. 19

Default = 0.0 (Real ≥ 0.0) Note: For

DISTOL=0.0, only the first layer of

elements on the surface of the model (encountered when

traveling in the build direction) is

supported. |

|

| SUPPSET | References the

identification number of a SET of grid points which identifies

regions of the model that are considered to be supported. Default = Blank (Integer > 0) |

|

| MILL | Indicates milling constraints are specified and the definitions of the required parameters are to follow. There are two ways to define the milling constraint – using the access angle (ANGLE) or the bit and clamp dimensions (R, B, and H). 27 | |

| ANGLE | Access Angle definition.

This angle is specified as the ratio of radius of the outer circle

to the depth of the milled hole. No Default (Real) |

|

| R | Radius of the mill

Bit. Default = Blank (Real) |

|

| B | Length of the mill

Bit. Default = Blank (Real) |

|

| H | Radius of the mill

Head. Default = Blank (Real) |

|

| OBST | Indicates that a list of

PIDs follow which are non-designable, but their interaction with

designable parts needs to be considered with regards to the milling

constraint. OBST stands for obstacle. Only recognized if MILL flag is also present on the same DTPL card. If the OBST flag is present without the MILL flag, the run is terminated with an error. |

|

| OPID# | Obstacle property

identification number. List of non-designable properties that are to

be considered with regards to the milling constraints. These must be

PSOLID IDs. No default (Integer > 0, Blank or ALL) |

Comments

- The von Mises stress constraints may be

defined for topology and free-size optimization through the

STRESS optional continuation line on the

DTPL or the DSIZE card. There are a number of restrictions with this constraint:

- The definition of stress constraints is limited to a single von Mises permissible stress. The phenomenon of singular topology is pronounced when different materials with different permissible stresses exist in a structure. Singular topology refers to the problem associated with the conditional nature of stress constraints, that is, the stress constraint of an element disappears when the element vanishes. This creates another problem in that a huge number of reduced problems exist with solutions that cannot usually be found by a gradient-based optimizer in the full design space.

- Stress constraints for a partial domain of the structure are not allowed because they often create an ill-posed optimization problem since elimination of the partial domain would remove all stress constraints. Consequently, the stress constraint applies to the entire model when active, including both design and non-design regions, and stress constraint settings must be identical for all DSIZE and DTPL cards.

- The capability has built-in intelligence to filter out artificial stress concentrations around point loads and point boundary conditions. Stress concentrations, due to boundary geometry are also filtered to some extent as they can be improved more effectively with local shape optimization.

- Due to the large number of elements with active stress constraints, no element stress report is given in the table of retained constraints in the .out file. The iterative history of the stress state of the model can be viewed in HyperView or HyperMesh.

- Stress constraints do not apply to 1D elements.

- Stress constraints may not be used when enforced displacements are

present in the model.Note: The functionality of the STRESS continuation line to define topology stress constraints consists of many limitations. It is recommended to use DRESP1-based Stress Responses. Actual Stress Responses for Topology and Free-Size (Parameter) Optimization are available through corresponding Stress response RTYPE's on the DRESP1 Bulk Data Entry. The Stress-NORM aggregation is internally used to calculate the Stress Responses for groups of elements in the model.

- It is recommended that a

MINDIM value be chosen such that it is at least 3 times,

and no greater than 12 times, the average element size. When pattern grouping,

draw direction, or extrusion constraints are active, a MINDIM

value of 3 times the average element size is enforced, and user-defined values

(which are smaller than this value) will be replaced by this value. However, in

cases where a MINDIM greater than 12 times the average

element size is defined, irrespective of whether, or not other manufacturing

constraints are defined, the value is reset to be equal to 12 times the average

element size. If DOPTPRM,TOPDISC is

present in the model, a MINDIM value equal to 2 times the

average element size is enforced.

If MINDIM is defined, but no other manufacturing constraint exists, MINDIM will not be reset to the recommended lower bound value for PTYPE=PSHELL or PSOLID, if the defined value is less than the recommended value. For PTYPE=PCOMP, MINDIM will be reset in the absence of manufacturing constraints.

- MAXDIM should be at

least twice the value of MINDIM. If the input value of

MAXDIM is too small, OptiStruct automatically resets the value and an INFORMATION message is printed.

The MAXDIM constraint introduces significant restriction to the design problem. Therefore, it should only be used when it is a necessary design requirement. A study without MAXDIM should always be carried out in order to compare the impact of this additional constraint.

MAXDIM implies the application of a MINGAP constraint of the same value as MAXDIM, as well. For the traditional Density method (SIMP) method, for MINGAP to be effective, it should be greater than MAXDIM. For Level Set method, MINGAP should be lower than MAXDIM.

It is important to pay attention to volume fraction as the achievable volume is below 50% when MAXDIM is defined, and further decreases as MINGAP increases.

- MTYP=ALIGN may be used in

conjunction with draw direction or extrusion manufacturing constraints to

indicate that a mesh is aligned with a draw direction or extrusion path.

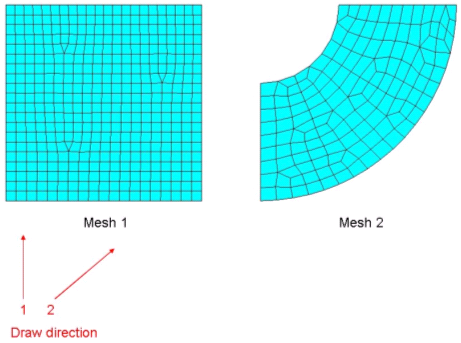

Figure 1. Draw Direction

Mesh 1 is "aligned" for draw direction 1 in the example shown, but not for draw direction 2.

MTYP=ALIGN may also be used in conjunction with manufacturing constraints (minimum member, maximum member, pattern grouping, and pattern repetition) other than draw direction and extrusion, and Mesh 1 is considered "aligned" for those manufacturing constraints, too.

In both cases, this will enable OptiStruct to use a smaller minimum member size and smaller maximum member sizes. The default minimum member size is three times the average element edge length; with an "aligned" mesh, the default size can be two times the average element edge length.

Mesh 2 in the example shown is not "aligned" in any case.

- The stamping constraint is available for

only one sheet, which is defined by the combination of STAMP

and DTYP as SINGLE.

It is recommended that the stamping thickness, TSTAMP, be chosen such that it is at least 3 times the average element size. If TSTAMP is defined less than the minimum recommended value, TSTAMP will be reset to the minimum recommended value.

STAMP and NOHOLE can be a good combination as this helps to produce a continuous/spread shell structure.Note: Attention should be paid to the compatibility between thickness and target volume. - Extrusion constraints cannot be combined with draw direction constraints.

- Pattern repetition allows similar regions

of the design domain to be linked together so as to produce similar topological

layouts. This is facilitated through the definition of "Main" and "Secondary"

regions. A DTPL card may only contain one

MAIN or SECOND flag. Parameters will

not be exported for any DTPL cards containing the

SECOND flag. For both "Main" and "Secondary" regions, a

pattern repetition coordinate system is required and is described following the

COORD flag. To facilitate reflection, the coordinate

system may be a left-handed or right-handed Cartesian system. The coordinate

system may be defined in one of two ways, listed here in order of precedence:

- Four points are defined and these are utilized as follows to define the

coordinate system (this is the only way to define a left-handed system):

- A vector from the anchor point to the first point defines the x-axis.

- The second point lies on the x-y plane, indicating the positive sense of the y-axis.

- The third point indicates the positive sense of the z-axis.

- A rectangular coordinate system and an anchor point are defined. If only an anchor point is defined, it is assumed that the basic coordinate system is to be used.

Multiple "Secondary" may reference the same "Main."

Scale factors may be defined for "Secondary" regions, allowing the "Main" layout to be adjusted via the SCALE continuation line.

For a more detailed description, refer to Pattern Repetition in the Topology Optimization Manufacturability section of the User Guide.

- Four points are defined and these are utilized as follows to define the

coordinate system (this is the only way to define a left-handed system):

- For historic reasons, the SYMM flag may be used in place of the PATRN flag.

- Currently there are six pattern grouping

options:

1-plane symmetry (TYP=1)

This type of pattern grouping requires the anchor point and first point to be defined. A vector from the anchor point to the first point is normal to the plane of symmetry.

2-plane symmetry (TYP=2)

This type of pattern grouping requires the anchor point, first point, and second point to be defined. A vector from the anchor point to the first point is normal to the first plane of symmetry. The second point is projected normally onto the first plane of symmetry. A vector from the anchor point to this projected point is normal to the second plane of symmetry.

3-plane symmetry (TYP=3)

This type of pattern grouping requires the anchor point, first point, and second point to be defined. A vector from the anchor point to the first point is normal to the first plane of symmetry. The second point is projected normally onto the first plane of symmetry. A vector from the anchor point to this projected point is normal to the second plane of symmetry. The third plane of symmetry is orthogonal to both the first and second planes of symmetry, passing through the anchor point.

Uniform Pattern Grouping (TYP=9)

This type of pattern grouping does not require any additional input. It only requires the TYP field to be set equal to 9. All elements included in this DTPL entry are automatically considered for uniform pattern grouping. All elements on this DTPL entry are set equal to the same element density with respect to one another.

Cyclic (TYP=10)

This type of pattern grouping requires the anchor point, first point, and number of cyclical repetitions to be defined. A vector from the anchor point to the first point defines the axis of symmetry.

Cyclic with symmetry (TYP=11)

This type of pattern grouping requires the anchor point, first point, second point, and number of cyclical repetitions to be defined. A vector from the anchor point to the first point defines the axis of symmetry. The anchor point, first point, and second point all lay on a plane of symmetry. A plane of symmetry lies at the center of each cyclical repetition.

For a more detailed description, refer to Pattern Grouping in the Topology Optimization Manufacturabilitysection of the User Guide.

- The LT field can be used to specify the lattice type used in Lattice Structure Optimization for hexahedral elements.

- The density thresholds are defined using the LB and UB fields on the LATTICE continuation line. Elements with densities below LB (real) are considered voids and removed for the second phase. Elements with densities above UB (real) are considered solid and are retained as solid elements for the second phase. Elements with densities between LB and UB are considered as porous phases and elements having these densities are replaced by lattice structures. The amount of intermediate densities (between 0.0 and 1.0) is controlled using DOPTPRM, POROSITY. For further information, refer to Lattice Structure Optimization in the User Guide.

- FailSafe topology optimization runs in

SPMD mode and requires the

-fsoscript option. For further information, refer to Failsafe Topology Optimization in the User Guide. - Multi-Model Optimization requires the

definition of the COORD continuation line to allow mapping of

the design domains among multiple models. If individual pattern repetition is

defined on all models, then this continuation line is not required as the

COORD data from the pattern repetition section is used

instead. The coordinate system can be defined in one of two different ways:

- Four points are defined, and these are utilized as follows to define the

coordinate system (this is the only way to define a left-handed

system):

A vector from the anchor point to the first point defines the x-axis.

The second point lies on the x-y plane, indicating the positive sense of the y-axis.

The third point indicates the positive sense of the z-axis.

- A rectangular coordinate system and an anchor point are defined. If only an anchor point is defined, it is assumed that the basic coordinate system is to be used.

- Four points are defined, and these are utilized as follows to define the

coordinate system (this is the only way to define a left-handed

system):

- Both solids and shells are supported in

multiple materials topology optimization. The following two limitations apply to

PSHELLs in the design space for multiple materials

topology optimization.

- For any PSHELL entry part of the design space, then all material reference fields (MID# fields) on each PSHELL entry should point to the same material entry.

- Additionally, if multiple PSHELL entries are part of the design space, then all MID# fields on all PSHELL entries should point to the same material entry.

- The original material defined by its property will be taken as one of the candidate material by default. Besides the original one, the maximum number of candidate materials is nine (9). Only isotropic material MAT1 is supported on the MID# fields.

- The Rational Approximation for Material

Properties (RAMP) method uses the following equation for

penalization.Where,

- Penalized stiffness matrix of an element (as a function of density)

- Actual stiffness matrix of an element

- Density

- Penalization factor

For information about Solid Isotropic Material with Penalty (SIMP) method, refer to Design Elements in the User Guide.

- Overhang constraints are supported for both the traditional Density method (SIMP) and Level Set method. For overhang constraints, STEP=1 allows aggressive move limits and typically converges fast. It generally produces good results for a majority of situations. However, it may show large fluctuations in convergence. In such cases, STEP=2 can be tried, which moves conservatively and follows a smoother convergence curve. It may sometimes offer faster convergence and better designs.

- If the METHOD field

is set to CONSTR, then the following considerations are available:

- Depending on the model, CONSTR method can pose a significant reduction of the design freedom for the optimization. Which may lead to a reduction in performance compared to the run without overhang constraints.

- If a volume or mass constraint is used in addition to the overhang constraint with CONSTR, then the target may be too low for the optimizer to find a good design. In such cases, you can try increasing the volume or mass target.

- If the impact on the performance or the volume/mass target is too large, then try the PENALTY method.

If the METHOD field is set to PENALTY, then the following considerations are available:- This method is good at removing members that are overhanging but have a small or medium impact on the performance. This method may not remove members which are very important to performance. If the goal is to remove such high impact members, try the CONSTR method instead.

- For PENALTY method, the violations of overhang angle are output to H3D file.

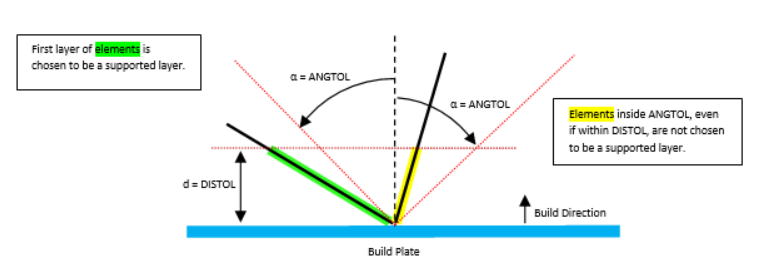

- The ANGTOL and

DISTOL fields can be used to define elements that are

considered to always be supported during optimization. Candidate elements are

all those elements in the first layer encountered when traveling in the build

direction. If this layer is inclined more than ANGTOL, and

lies within DISTOL, it is always supported.The elements which are always supported are output to the H3D file under the “Predefined Support” results type. For the actual manufacturing of the part, some sections of this predefined support might require support structure.

Figure 2.

- LATPRM,LATSUP can be used to define the maximum volume fraction of the lattice support regions when overhang constraints are used in Topology Optimization.

- The level set method can merge existing holes but cannot nucleate new holes in the design domain, unless TOPDER is defined. Therefore, creating an initial design with holes is necessary, especially for 2D design problems (For 3D design problems, new holes can be “tunneled” when two surfaces merged).

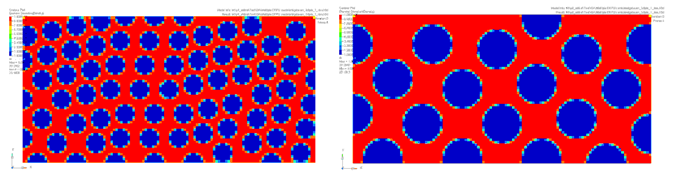

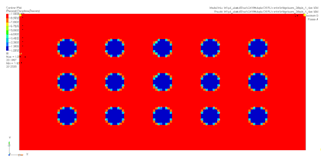

- By default, OptiStruct will automatically create a Cheese-like

initial design with holes adaptively distributed over the design domain (Figure 3) The default hole radius is 5.0 times the average

mesh size.

Figure 3. A Cheese-like Initial Design Generated . (left) with default setting; (right) double hole radius

- Changing the value of

HOLERAD can result in different initial designs. Figure 3(right) shows an initial design filled with holes

possessing a doubled hole radius when compared to Figure 3(left). If you want to create an initial design with

evenly distributed and well aligned holes (this may be preferable for regular

design domains), HOLEINST can be set to

ALIGN. The number of holes in each direction can be further

specified by using NHOLESX, NHOLESY and

NHOLESZ (Figure 4).

Figure 4. A Cheese-like Initial Design with 3-by-5 Evenly Distributed Holes . (generated using: HOLEINST=ALIGN, NHOLESX=5 and NHOLESY=3)

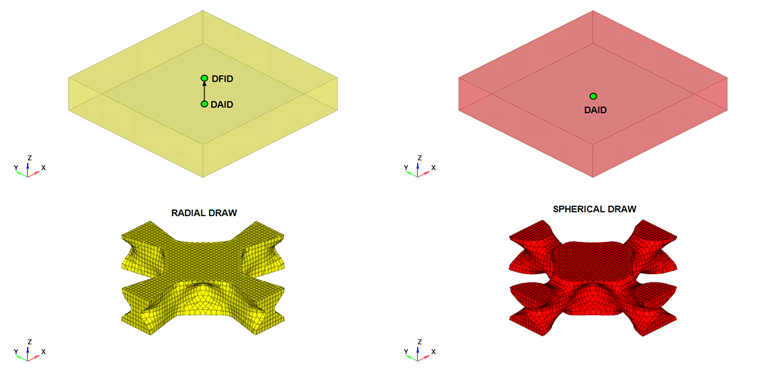

- The Radial draw direction option allows

you to define manufacturing constraints for draw such that the die can be

withdrawn in a radially outward direction away from the cylindrical axis defined

by DAID → DFID. The Spherical draw

direction option allows you to define manufacturing constraints for draw such

that the die can be withdrawn in a spherically outward direction away from the

central point defined by DAID. The anchor grid for spherical

draw direction is recommended to be placed in the center of geometry.

Figure 5. Radial and Spherical Draw Direction

- For more information, refer to Level Set Method in the User Guide.

- When

PTYPE=SET on DTPL

entry, then:

- The referenced element set can contain elements referring to only PSHELL and PSOLID properties.

- Both PSHELL and PSOLID elements should not be included in the same design space.

- The same element should not be used in multiple design spaces.

- If T0 is defined on the DTPL entry

and/or the PSHELL entry, they must be consistent.

That is,

- T0 on all the DTPL entries

using elements from the same PSHELL should

match.

For example, DTPL#1 with T0=0.0 and DTPL#2 with T0=1.0 and both referring to elements from the same PSHELL is not allowed.

- If T0 on a PSHELL is defined, then its value should match with T0 defined on all DTPL entries with PTYPE=SET that reference elements from this PSHELL.

- T0 on all the DTPL entries

using elements from the same PSHELL should

match.

- Multi-material, level set and lattice optimization are not supported

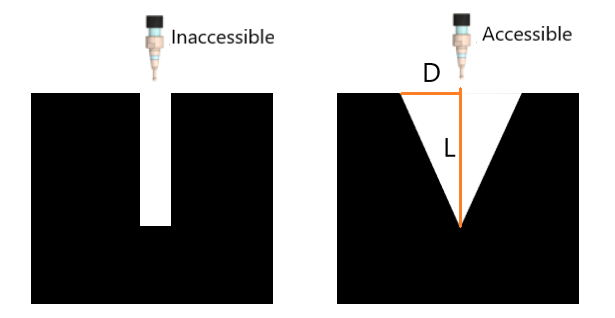

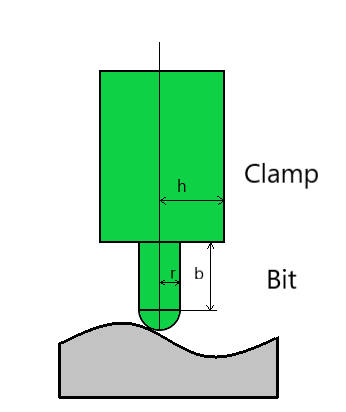

- There are two ways to define milling

constraints for Topology optimization. One option is to define the access angle

directly using the ANGLE field, where

ANGLE is the ratio D/L as shown in Figure 6. The second

option is to define the dimensions of the milling bit and head using the

R, B, and H fields

(which are equivalent to the r, b, and h values in Figure 7). The

OBST keyword and continuation can be used to define

obstacles to be considered during milling constraint optimization.

Figure 6.

Figure 7.

- This card is represented as an optimization design variable in HyperMesh.