PBEAML

Bulk Data Entry Defines the properties of a beam element by cross-sectional dimensions that are used to create beam elements via the CBEAM entry.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| PBEAML | PID | MID | GROUP | TYPE/ NAME |

ND | ||||

| DIM1(A) | DIM2(A) | etc | NSM(A) | SO(1) | X(1)/ XB |

DIM1(1) | DIM2(1) | ||

| etc | NSM(1) | etc | SO(B) | X(B)/ XB |

DIM1(B) | DIM2(B) | etc | ||

| NSM(B) |

* The format of this Bulk Data Entry is somewhat unusual as the field locations can vary depending on the number of dimensions used to define the cross-section.

Optional continuation line for cross section integration (section type BAR & ROD only):

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| + | INT | Q_ORDER |

Example

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| PBEAML | 99 | 21 | T | ||||||

| 12. | 14.8 | 2.5 | 26. | NO | 0.4 | 6. | |||

| 7. | 1.2 | 2.6 | YES | 0.6 | 6. | 7.8 | |||

| 5.6 | 2.3 | YES |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| PID | Unique simple beam property

identification.

No default (Integer > 0 or <String>) |

|

| MID | Material identification. 1

2

No default (Integer > 0 or <String>) |

|

| GROUP | Indicates if an arbitrary beam section

definition is to be used. Refer to Arbitrary Beam Section Definition in the User Guide.

If the value of this field is HYPRBEAM, the following field is

NAME; otherwise it is TYPE. Default = blank (blank or HYPRBEAM) |

|

| TYPE | Cross-section shape. When

GROUP field is blank, this field is

TYPE. No default (BAR, BOX, BOX1, CHAN, CHAN1, CHAN2, CROSS, H, HAT, HEXA, I, I1, L, ROD, T, T1, T2, TUBE, or Z) |

|

| NAME | Name of arbitrary beam section

definition. Refer to Arbitrary Beam Section Definition in the

User Guide. When the value of GROUP is

HYPRBEAM, this field is NAME. No default (Character string) |

|

| ND | Number of dimensions used to specify the

Cross-section shape. This is required when the value of the GROUP

field is HYPRBEAM. ND represents the total

number of dimensions used to define an Arbitrary Beam Section. Default = blank |

|

| DIMi(A) | Cross-section dimensions at end A. No default (Real > 0.0) |

|

| NSM(A) | Nonstructural mass per unit length at

end A. Default = 0.0 (Real) |

|

| SO(#) | Stress output request option for

intermediate station #. Stress output is not supported for intermediate stations so this field must be set to NO. |

|

| X(#)/XB | Distance from end A to intermediate

station # in the element coordinate system, divided by the length of the

element. Default = 1.0 (Real > 0.0) |

|

| DIMi(#) | Cross-section dimensions at intermediate

station #. (Real > 0.0) |

|

| NSM(#) | Nonstructural mass per unit length at

intermediate station #. Default = 0.0 (Real) |

|

| SO(B) | Stress output request option for end

B.

|

|

| X(B)/XB | Distance form end A to end B in the

element coordinate system, divided by the length of the element. This must be 1.0 |

|

| DIMi(B) | Cross-section dimensions at end

B. (Real > 0.0) |

|

| NSM(B) | Nonstructural mass per unit length at

end B. Default = 0.0 (Real) |

|

| INT | Continuation line flag indicating that beam integration information is to follow. | |

| Q_ORDER | Quadrature order for cross-section

integration. Defines the quadrature order for calculating the number of integration

points automatically distributed in the section (for BAR and ROD section types

only). Q_ORDER defines the number of sub-sections in the beam

cross-section.

|

Comments

- For structural problems, MID may reference only a MAT1 material entry. For heat transfer problems, MID may reference only a MAT4 material entry.

- String based labels allow for easier visual identification of properties, including when being referenced by other cards. (For example, the PID field of elements). For more details, refer to String Label Based Input File in the Bulk Data Input File.

- Up to eleven stations are allowed (end A and B, and nine intermediate stations #).

- The cross-sectional properties, shear

flexibility factors, and stress recovery points (C, D, E, and F) are computed using the

TYPE and DIMi as shown below. The element

coordinate system is located at the shear center.

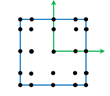

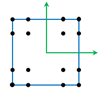

Figure 1. TYPE = BAR

Figure 2. TYPE = BOX

Figure 3. TYPE = BOX1

Figure 4. TYPE = CHAN

Figure 5. TYPE = CHAN1

Figure 6. TYPE = CHAN2

Figure 7. TYPE = CROSS

Figure 8. TYPE = H

Figure 9. TYPE = HAT

Figure 10. TYPE = HEXA

Figure 11. TYPE = I

Figure 12. TYPE = I1

Figure 13. TYPE = L

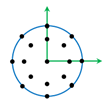

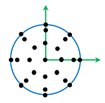

Figure 14. TYPE = ROD

Figure 15. TYPE = T

Figure 16. TYPE = T1

Figure 17. TYPE = T2

Figure 18. TYPE = TUBE

Figure 19. TYPE = Z

- For PBEAML entries with more than one section, an equivalent PBEAM entry is derived. An echo request will cause a printout of the derived PBEAM.

- Stress recovery is only allowed at end A and end B. Stress recovery at intermediate stations is not supported.

- For

TYPE=ROD, if

X(1)/XB is equal to 1.0, then the

DIM(1)A references the radius of the beam at end A and

DIM(1)B references the radius of the beam at end B and there are no

intermediate stations. This element is a tapered beam formulation, and averaging is not

used to determine the average radius of the beam. Instead, the true tapered beam

formulation is used with the given dimensions. The true tapered beam formulation is only

available for TYPE=ROD.

Figure 20.

- DIMi and NSM have to be specified fully on station A. On station B, blank means that the dimensions are the same as at A. On other stations, it is a linear interpolation between A and B.

- The NSM specified at end A

is the default value for NSM at end B. The default for all other

stations is a linear interpolation between end A and end B. So, for a constant

NSM over the length of the beam, only NSM at end A

is required.

The mass of the element is calculated as:

If the NSM value is different in different stations, it is averaged over all the stations and the average is used in the element calculation.

- For TYPE=ROD or

TYPE=BAR, the integrated beam formulation is

available. In this case, the beam is computed using cross-section integration. The

integration points are automatically distributed in the section according to the

quadrature order and the type of the section. For BAR, the number of

integration points is Q_ORDER*Q_ORDER. For

TYPE=ROD and

TYPE=BAR, the integrated beam formulation is

automatically activated with default parameters if the reference material is

MATS1.

Some examples of integration point distribution in beam cross sections based on the Q_ORDER value are shown below:

Figure 21. BAR Section Q_ORDER = 5 (Default)

Figure 22. BAR Section Q_ORDER = 4

Figure 23. ROD Section Q_ORDER = 4 (Default)

Figure 24. ROD Section Q_ORDER = 5

- This card is represented as a property in HyperMesh.