CONTACT

Bulk Data Entry Defines a contact interface.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| CONTACT | CTID | PID/ TYPE /MU1 |

SSID | MSID | MORIENT | SRCHDIS | ADJUST | CLEARANCE | |

| DISCRET | TRACK | CORNER | ROT | SORIENT |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| + | SMOOTH | SMSIDE | SMREG | SMTYPE | |||||

| ± | SMTPAR1 | SMTPAR2 | SMTPAR3 | SMTPAR4 | SMTPAR5 | SMTPAR6 |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| + | PSURF | PSID1 | PSID2 |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| + | COHE | MCOHEDID | COHEGSET |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| + | WEAR | KWEAR | HARDNESS | A | B |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| + | MNTREF | REFPOINT/X | Y | Z |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| + | COORD | CID |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| + | ACTIVA | ACTID_A1 | ACTID_B1 | METHOD | |||||

| ACTID_A2 | ACTID_B2 | METHOD | |||||||

| + | DEACTIVA | DEACTID_A1 | DEACTID_B1 | ||||||

| DEACTID_A2 | DEACTID_B2 | ||||||||

| + | PCONT | ACTID_A1 | ACTID_B1 | PID1 | |||||

| ACTID_A2 | ACTID_B2 | PID2 | |||||||

| etc. | etc. | etc. | |||||||

| + | PSURF | ID1 | PSID1 | ||||||

| ID2 | PSID2 |

Example 1

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| CONTACT | 5 | SLIDE | 7 | 8 | |||||

| N2S |

Example 2

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| CONTACT | 5 | SLIDE | 7 | 8 | |||||

| S2S | |||||||||

| SMOOTH | SECOND | 71 | |||||||

| SMOOTH | SECOND | 72 | |||||||

| SMOOTH | MAIN | ALL |

Example 3 (Auto-Contact)

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| CONTACT | 23 | AUTO | |||||||

| ACTIVA | ALL | ||||||||

| PSURF | ALL | 11 |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| CTID | Contact interface

identification number. (Integer > 0) |

|

| PID | Property identification of

a PCONT Bulk Data Entry.

(Integer > 0 or <String> (only for PCONT)) |

|

| TYPE | Choose type of contact

without pointing to contact property - respective default property

settings will be used. Default settings can be changed using CONTPRM. 4

|

|

| MU1 | Coefficient of static

friction (

). 5 (0.0 ≤ Real < 1.0) |

|

| SSID | Secondary entity

identification. 1

2

|

|

| MSID | Main entity

identification. 1

2

|

|

| MORIENT | Orientation of contact

"pushout" force from main surface. Applies only to mains that

consist of shell elements or patches of grids. Mains defined on

solid elements always push outwards irrespective of this flag. 6

18

Default = OPENGAP (if TRACK is not set to CONSLI) or NORMAL (if TRACK=CONSLI) |

|

| SRCHDIS | Search distance criterion

for creating contact condition. When specified, only secondary nodes

that are within SRCHDIS distance from main

surface will have contact condition checked. 6 Default = Twice the average edge

length on the main surface. For FREEZE contact,

half the average edge length. (Real > 0 or blank) Note: For Node-to-Node (N2N) discretization,

if SRCHDIS is blank, search distance is

ignored and it is guaranteed to find a contact pair

irrespective of the interface gap. |

|

| ADJUST | Adjustment of secondary

nodes onto the main surface at the start of a simulation. 6

For Node-to-Node (N2N) discretization, the default is NO and Real value can be specified for the depth criterion, similar to other discretization types. AUTO and Integer do not apply for N2N discretization. |

|

| CLEARANCE |

|

|

| DISCRET | Discretization approach type for the construction of contact elements. 1 | |

| TRACK | Types of sliding contact.

|

|

| ROT | Constraining rotational

degrees of freedom for N2S and S2S FREEZE contact. 23 This option is ignored for N2S FREEZE contact with a CGAPG core.

|

|

| SORIENT | Orientation of contact

force applied on the secondary surface (which should be in the same

direction as the pushout force from the main surface). This field is

only relevant when the secondary surface consists of shell elements

with S2S (CONSLI) contact. 18

|

|

| CORNER | Corner treatment for the

secondary surface of N2S and S2S contacts. 11

|

|

| SMOOTH | Continuation lines for surface smoothing definition flag. 6 | |

| SMSIDE | Main and/or secondary

side(s) of the contact interface to be smoothed. 6

No default |

|

| SMREG | Specifies the region at

the main/secondary surface to be smoothed. 6

|

|

| SMTYPE | Specifies the smoothing

method. 6

|

|

| SMPARi | Specifies the smoothing

parameters if SMTYPE =

CIRCUM/SPHERIC. 6 If SMTYPE = CIRCUM: SMTPAR1 through SMTPAR6 are specified to define the axis of symmetry passing through two points (SMTPAR1, SMTPAR2, SMTPAR3) and (SMTPAR4, SMTPAR5, SMTPAR6). If SMTYPE = SPHERIC: SMTPAR1 through SMTPAR3 are specified to define the center point (SMTPAR1, SMTPAR2, SMTPAR3) of the spherical surface. SMTPAR4 through SMTPAR6 should not be specified. No default (Real) Note: This continuation line should not be

present if SMTYPE =

Blank. |

|

| PSURF | Continuation line for surface property assignment. Only supported for explicit analysis. | |

| PSID1 | The

PSURF entry ID which is used to define the

secondary surface property. No default (Integer > 0) |

|

| PSID2 | The

PSURF entry ID which is used to define the

main surface property. No default (Integer > 0) |

|

| COHE | Continuation line for cohesive material. 17 | |

| MCOHEDID | Identification number of

MCOHED card that is referenced by the current

contact. No default (Integer > 0) |

|

| COHEGSET | Cohered grid set. 13

|

|

| WEAR | Flag indicating the required parameters for Wear output are to follow.CONTF I/O Option is also required for Wear output. 26 | |

| KWEAR | Wear coefficient. No default (Real > 0) |

|

| HARDNESS | Hardness of material on

the secondary side. No default (Real > 0) |

|

| A | Exponent on pressure in

Archard wear equation. Default = 1.0 (Real > 0) |

|

| B | Exponent on sliding

velocity in Archard wear equation. Default = 1.0 (Real > 0) |

|

| MNTREF | Flag indicating that the reference point definition for the contact moment calculation is next. | |

| REFPOINT | Reference point

definition. 25

|

|

| COORD | Flag indicating that the coordinate system definition for the contact resultant force and resultant moment output is to follow. 27 | |

| CID | ID of the coordinate system in which contact resultant force and resultant moment are output in .cntf file. | |

| ACTIVA | Flag indicating that the following fields indicate the surfaces for which the auto-contact is activated. 19 20 | |

| ACTID_Ai |

No default |

|

| ACTID_Bi |

Default = Blank |

|

| METHOD | Controls the type of

surface identified via the ACTID_Ai and

ACTID_Bi fields on the

ACTIVA continuation line.

|

|

| DEACTIVA | Flag indicating that the following fields indicate the surfaces for which the auto-contact is to be deactivated. 19 21 | |

| DEACTID_Ai |

No default |

|

| DEACTID_Bi |

No default |

|

| PCONT | Flag indicating that the following fields reference contact interfaces to which the corresponding PCONT PID applies. | |

| ACTID_Ai |

No default |

|

| ACTID_Bi |

Default = Blank |

|

| PIDi | References the

identification number of a PCONT entry. No default (Integer > 0) |

|

| PSURF | Flag indicating that the following fields reference contact interfaces to which the corresponding PSURF PIDs apply. | |

| IDi |

No default |

|

| PSIDi | References the identification number of PSURF entries. |

Comments

- A general set of guidelines for

secondary/main selection are:

- Select the surface with finer mesh as the secondary and the other as the main.

- Select the smaller surface as the secondary and the other as the main.

- Select the softer surface as the secondary and the other as the main.

For information regarding choosing between N2S and S2S contact, refer to Contact Discretization in the User Guide.

- The secondary entity

(SSID) always consists of grid nodes. It may be specified as:

- A set of grid nodes defined using SET(GRID, ..) command

- A surface defined using SURF command (the secondary nodes are picked from the respective nodes of the SURF faces)

- A set of elements (shells or solids) defined using SET(ELEM, ..) command. Secondary nodes are picked from the respective nodes of the elements in the set. For 3D solids, only nodes on the surface of the solid body are selected; internal nodes are not considered.

DISCRET=N2S is recommended if the secondary entity is a set of grids (nodes) or a set of solid elements.

- The main entity

(MSID) may be defined as:

- A surface defined using SURF command.

- A set of elements (shells or solids) defined using SET(ELEM, ..) command. For sets of 3D solids, element faces on the surface are automatically found and selected as main surface.

- The MSID can be left blank or set the same as SSID to activate Self Contact condition. This is currently supported only for Node-to-Surface (N2S) and Surface-to-Surface (S2S) contact with Continuous Sliding (CONSLI). For further information, refer to Self-Contact in the User Guide.

- For N2N discretization, MSID should refer to a GRID set defined by the SET entry.

- For information on the different contact interfaces (TYPE field options), refer to Contact Interface Types in the User Guide.

- MU1 directly on the

CONTACT card allows for simplified specification of

frictional contacts.Note: This implies MU2=MU1, unless MU2 is specified explicitly on the CONTPRM card. Also, the value of MU1 assigned on the CONTACT card must be less than 1.0 - to specify higher values of static coefficient of friction, the PCONT card must be used.

If FRIC is not explicitly defined on the PCONTX/PCNTX# entries, the MU1 value on the CONTACT or PCONT entry is used for FRIC in the /INTER entries for Explicit Dynamic Analysis. Otherwise, FRIC on PCONTX/PCNTX# overwrites the MU1 value on CONTACT/PCONT. For further information regarding frictional contact, refer to Friction in the User Guide.

- For information regarding the different contact parameters (ADJUST, CLEARANCE, MORIENT, TRACK, SMOOTH, SRCHDIS, GPAD), refer to Contact Interface Parameters (Contact Control) in the User Guide.

- Contact stabilization for Surface-to-Surface Contact and Node-to-Surface contact can be activated using the CNTSTB Subcase Information and CNTSTB Bulk Data Entries. Additionally, PARAM, EXPERTNL,CNTSTB can be used to activate contact stabilization. The CNTSTB Bulk Data parameters override the parameter values for a particular subcase.

- Thermal-structural analysis problems involving contact are fully coupled since contact status changes thermal conductivity. For further information, refer to Contact-based Thermal Analysis in the User Guide.

- Applying rotational SPC on nodes which belong to a FREEZE contact should be avoided. Fixing the rotational degrees of freedom will prevent the rotation of these contact nodes even in the case of solid elements.

- In continuous-sliding contact (TRACK=CONSLI), the contact search is conducted for every contact iteration. In the formulation of contact virtual work, every term is updated based on the status in current iteration. The contact tangent stiffness matrix is computed in a consistent way. Continuous-sliding contact is expected to produce more accurate results and in some cases, better convergence robustness, especially when very large sliding and/or distortion are present.

- Corner treatment is supported for N2S (only for TRACK=CONSLI) and S2S (for all TRACK options) contacts. When corner treatment is turned on (AUTO or Real value), the contact surface around a secondary node may be divided into several continuous surface patches if break angle criteria are satisfied on one or more edges at the node. For each surface patch, a separate contact element will be created for the element stiffness matrix, element force vector and element history variables computation. Corner treatment may improve robustness and accuracy in some cases.

- The CONTACT entry

is supported for:

- Linear and Nonlinear Static Analysis

- Linear and Nonlinear Transient Analysis

- Linear Dynamic Analysis

- Heat Transfer Analysis

- Contact-based Thermal Analysis (HEAT)

- N2S option should be used to activate large shape change during shape optimization. Currently, large shape change is activated if the model has N2S contact or CGAP/CGAPG/CWELD/CFAST/CSEAM elements.

- N2N discretization is currently only supported for Small Displacement Nonlinear Analysis.

- The following comments apply to

Edge-to-Edge contact via PSURF field.

- PSURF field is only supported for explicit analysis.

- The secondary side must be surface-based (cannot be grid-based).

- PSURF should be defined for both secondary and main.

- Shell boundary edges are not currently supported.

- Axisymmetric and plane-strain

contacts are supported for axisymmetric elements (CQAXI,

CTAXI, and CTRIAX6 elements) and

plane-strain solid elements (CQPSTN and

CTPSTN elements). The SURF

entry can be used to define the Main and Secondary surfaces. Axisymmetric and plane-strain contacts are currently supported for:

- SMALL (small sliding) for both N2S and S2S discretization

- CONSLI (continuous sliding) for N2S discretization

Axisymmetric and plane-strain contacts are not supported for:- CONSLI (continuous sliding) for S2S discretization

- Surface Smoothing

- Cohesive contact works only for small-sliding (TRACK=SMALL), frictionless (TYPE=SLIDE or MU1=0.0) N2S/S2S contact.

- In case of implicit analysis, the

shell contact surface orientation must be user-defined.

In case of explicit analysis, the shell contact surface orientation is automatically detected. Thus, you do not need to define consistent orientations on the surface.

- Auto-Contact is activated by setting the TYPE field to AUTO and is only applicable to explicit dynamics (NLEXPL) analysis, implicit nonlinear analysis (NLSTAT), and implicit nonlinear transient analysis (NLTRAN) analysis. ACTIVA continuation line is used to activate auto-contact, and DEACTIVA continuation line is used to deactivate certain contact interfaces from auto-contact. PCONT and PSURF continuation lines can be used to correspondingly activate Contact Properties and Edge Criteria for contact interfaces and surfaces.

- For ACTIVA, if

both ACTID_Ai and ACTID_Bi are defined,

then OptiStruct will internally generate components

based on these surfaces and detect all possible contact among them. For example, if you define:

+, ACTIVA, 1, 2 +, , 3, 4Then internally separate components are created based on surfaces 1, 2, 3, and 4. Contact is then automatically detected between these components. Self-contact inside each component is also detected.

Each surface can include multiple components (even the entire model can be a single surface). Internally, components are created for any defined surfaces. Component here implies a topologically connected geometry, like a bolt. Therefore, two separate bolts will be treated as two components even if they are defined as a single surface.

If ACTIVA,1 is defined, it indicates the self-contact of surface ID 1 and the METHOD field are ignored.

If ACTIVA,ALL,2 is defined, it indicates contact between surface ID 2 and the entire model, including itself.

If ACTIVA,1,ALL is defined, it indicates contact between surface ID 1 and the entire model, including itself.

- DEACTIVA is

specifically intended to disable unwanted contact inside the model. For

DEACTIVA and PCONT, the order of

surface IDs does not matter. For example, if you define:

+, DEACTIVA, 1, 2 +, , 3, 4Then contacts between faces in surface 1 and surface 2 are deactivated. Similarly, contact between faces in surface 3 and surface 4 are also deactivated. Self-contact within surface 1 and self contact within surface 2 and so on will not be deactivated. Additionally, contact between surfaces 1 and 3, or contact between surface 1 and 4, etc will not be deactivated.

To explicitly deactivate self-contact for a particular surface, for instance, surface 1, then the following line can be added:+, DEACTIVA, 1, 2 +, , 3, 4 +, ,1,1If there are any contact interfaces defined via Standard CONTACT or TIE entries, they will automatically be excluded in Auto-contact. For example,+, ACTIVA, ALL TIE,100,1,2The contact between surfaces 1 and 2 are excluded. An exception to this is that these exclusions occur only if surfaces 1 and 2 are defined in the ELFACE format. If the surface 1 is a nodal SET, then such surfaces are not excluded.

- String based labels allow for easier visual identification, including when being referenced by other entries. For more details, refer to String Label Based Input File.

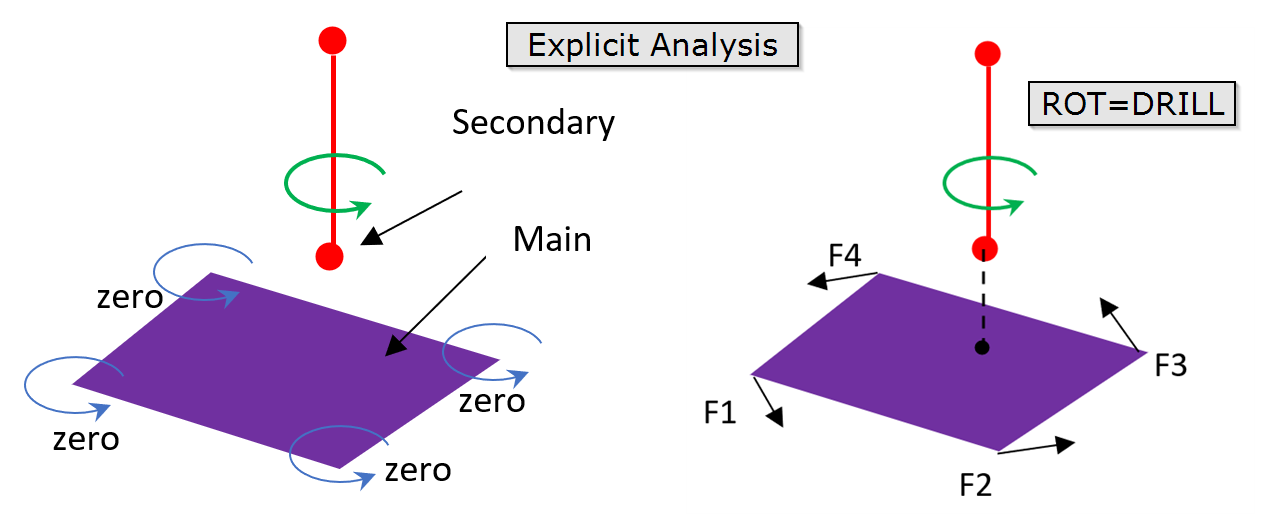

- The ROT option is

supported for both Implicit and Explicit analysis. For explicit analysis where

the main side is shell, if the DRILL option is specified for

ROT field of TIE and freeze

CONTACT entries, the moment on the secondary side will be

transferred to the main nodes as forces (instead of moments) as shown below. For

explicit analysis with main side as solids, this is active by default and the

ROT field has no effect.

Figure 1.

The following table shows support information for N2S TIE or N2S FREEZE contact (except for N2S TIE/FREEZE contact with a CGAPG core).N2S TIE/FREEZE Contact Linear Static/Transient/Modal Nonlinear Static Nonlinear Transient SMDISP/LGDISP Implicit (SMDISP/LGDISP) Explicit Rotational DOF (Main side is shell) ROT = YES (Default)/NO ROT = YES (Default)/NO ROT = YES (Default)/NO ROT = YES (Default)/NO/DRILL Rotational DOF (Main side is solid) ROT = YES (Default)/NO ROT = YES (Default)/NO ROT = YES (Default)/NO ROT = DRILL is always active and other options are not supported. - CLRNC ID can be specified on the CLEARANCE field in the CONTACT or PCONT Bulk Data Entry. If there is a conflict, then the CLRNC ID specified on PCONT takes precedence.

- Contact moment calculation/output

can be activated by the MNTREF continuation line. Each

contact can have its own reference point for contact moment calculation/output.

In a large displacement analysis, the location of a reference point defined by

GID or CENTER is updated with

deformation.

- Supported Analysis Types

- Nonlinear Static and Nonlinear Transient, for both small and large displacement analysis types. Explicit analysis (NLEXPL) is also supported.

- Supported Output Types

- OPTI (.cntf) only.

- Archard wear equation is used for

wear evaluation:Where,

- Wear depth.

- Wear coefficient.

- Hardness of material on secondary side.

- Pressure.

- Sliding velocity

- ,

- Coefficients calibrated from experiments (defined as the A and B fields in this entry).

Where,- Wear loss volume.

- Contact normal force.

- COORD and CID for contact force resultant and contact moment resultant are supported for both implicit and explicit analysis.

- This card is represented as a group in HyperMesh.