MATS1

Bulk Data Entry Specifies strain-, rate-, and temperature-dependent material properties for use in applications involving nonlinear materials.

This entry is used if a MAT1 entry is specified with the same MID in a nonlinear subcase.

Format A (HR = 1 to 3)

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MATS1 | MID | TID | TYPE | H | YF | HR | LIMIT1 | ||

| TYPSTRN | TYPSTRT |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| DAMAGE | DMGINI_ID | DMGEVO_ID | PFAIL |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| JHCOOK | A | B | N | C | RSTRT |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| CFOAM | TSC |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| CSYMONDS | D | p |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| JHOLMQ | A | B | M | N | C | RSTRT | SMAX | ||

| T | HEL | PHEL | D1 | D2 | |||||

| K1 | K2 | K3 | BETA |

Example A (HR = 1, 2, 3)

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MATS1 | 17 | 28 | PLASTIC | 0.0 | 1 | 1 | 2.0E04 |

Format B.1 (HR = 6: Kinematic Hardening (NLKIN), TYPKIN=PARAM)

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MATS1 | MID | HR | |||||||

| + | |||||||||

| NLKIN | TYPKIN | NKIN | |||||||

| SIGY0 | C1 | G1 | C2 | G2 | etc. | TEMP | |||

| etc. | etc. | etc. |

Format B.2 (HR = 6: Kinematic Hardening (NLKIN), TYPKIN=HALFCYCL)

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MATS1 | MID | HR | |||||||

| + | |||||||||

| NLKIN | TYPKIN | NKIN | |||||||

| SIG | EPS | TEMP | |||||||

| etc. | etc. | etc. |

Format B.3 (HR = 6: Isotropic Hardening (NLISO), TYPISO=PARAM)

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MATS1 | MID | HR | |||||||

| + | |||||||||

| NLISO | TYPISO | NISO | |||||||

| SIGY0 | Q | B | TEMP | ||||||

| etc. | etc. | etc. | etc. |

Format B.4 (HR = 6: Isotropic Hardening (NLISO), TYPISO=TABLE)

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MATS1 | MID | HR | |||||||

| + | |||||||||

| NLISO | TYPISO | NISO | |||||||

| SIG | EPS | TEMP | |||||||

| etc. | etc. | etc. |

Example (HR = 6): Kinematic Hardening

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MATS1 | 17 | 6 | |||||||

| + | |||||||||

| + | NLKIN | PARAM | 10 | ||||||

| 120.0 | 1000.0 | 10.0 | 2000.0 | 20.0 | 3000.0 | 30.0 | 4000.0 | ||

| 40.0 | 5000.0 | 50.0 | 6000.0 | 60.0 | 7000.0 | 70.0 | 8000.0 | ||

| 80.0 | 9000.0 | 90.0 | 10000.0 | 100.0 |

Example (HR = 6): Combined Hardening

TYPKIN=PARAM, NLKIN=2, Temperature-dependent

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MATS1 | 17 | 6 | |||||||

| + | |||||||||

| + | NLKIN | PARAM | 2 | ||||||

| 120.0 | 1000.0 | 10.0 | 2000.0 | 20.0 | 23.0 | ||||

| 100.0 | 800.0 | 8.0 | 1800.0 | 18.0 | 27.0 | ||||

| 80.0 | 600.0 | 6.0 | 1600.0 | 16.0 | 35.0 | ||||

| NLISO | PARAM | 1 | |||||||

| 100.0 | 70 | 5.0 | 23.0 | ||||||

| 120.0 | 80 | 6.0 | 27.0 | ||||||

| 80.0 | 60 | 4.0 | 35.0 |

Example (HR = 6): Kinematic Hardening

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MATS1 | 17 | 6 | |||||||

| + | |||||||||

| + | NLKIN | HALFCYCL | 2 | ||||||

| 120.0 | 0.0 | 23.0 | |||||||

| 125.0 | 0.01 | 23.0 | |||||||

| 130.0 | 0.03 | 23.0 | |||||||

| 80.0 | 0.0 | 35.0 | |||||||

| 86.0 | 0.01 | 35.0 | |||||||

| 92.0 | 0.03 | 35.0 |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| MID | Identification of a MAT1 entry.

No default (Integer > 0 or <String>) |

|

| TID | Identification of a TABLES1, TABLEST, TABLEG or

TABLEMD entry. If H is given, this

field must be blank. 3

(Integer ≥ 0, <String> (only for TABLES1), or blank) |

|

| TYPE | Material nonlinearity type.

|

|

| H | Work hardening slope (slope of stress

versus plastic strain) in units of stress. For elastic-perfectly plastic cases,

H = 0.0. For more than a single slope in the plastic range, the

stress-strain data must be supplied on a TABLES1 or

TABLEG entry referenced by TID, and this

field must be blank. 2 (Real) |

|

| YF | Yield function criterion.

(Integer) |

|

| HR | Hardening rule.

Adjustable mixed hardening is selected by choosing a (Real) value for

HR:

(1, 2, 3, 6, or 0.0 < Real < 1.0) (Integer) |

|

| LIMIT1 | Initial yield point. The LIMIT1 field can be blank, if the initial yield point value is defined via a referenced TABLES1, TABLEG, TABLEST or TABLEMD entries on the TID field. OptiStruct will error out if LIMIT1 is blank and TID does not reference a TABLES1, TABLEG, TABLEST or TABLEMD entry. (Real > 0 or blank) |

|

| TYPSTRN | Specifies the type of strain used on the

x-axis of the table pointed to by TID. The strain type is

selected by one of the following values. 3,

5, 7, 10

(Integer) |

|

| TYPSTRT | Specifies the type of strain rate used

on the x-axis of the table pointed to by TID of

TABLEMD. The strain rate type is selected by one of the

following values. ,

(Integer) |

|

| CFOAM | Flag that identifies that the Crushable Foam model parameters are to follow. 10 | |

| TSC | Tensile stress cutoff. A nonzero,

positive value is recommended for realistic behavior. Default = 0.0 (Real ≥ 0.0) |

|

| JHCOOK | Flag that identifies that the Johnson-Cook hardening method parameters are to follow. 9 | |

| A | Material yield stress. No default (Real) |

|

| B | Coefficient to the plastic

strain. Default = 0.0 (Real) |

|

| N | Exponent to the plastic

strain. Default = 1.0 (Real) |

|

| C | Coefficient to the strain

rate. Default = 0.0 (Real) |

|

| RSTRT | Reference strain rate. Default = 1.0 (Real) |

|

| CSYMONDS | Flag that identifies that the Cowper-Symonds method parameters are to follow. 11 | |

| D | Cowper-Symonds strain rate

parameter. No default (Real) |

|

| p | Cowper-Symonds strain rate parameter.

No default (Real) |

|

| JHOLMQ | Flag that identifies that the Johnson-Holmquist model parameters are to follow. 18 | |

| A | Intact normalized strength constant.

No default (Real) |

|

| B | Fractured normalized strength constant.

No default (Real) |

|

| M | Fractured strength pressure exponent.

No default (Real) |

|

| N | Intact strength pressure exponent. No default (Real) |

|

| C | Strain rate coefficient. No default (Real) |

|

| RSTRT | Reference strain rate. No default (Real) |

[1/s] |

| SMAX | Maximum normalized fractured strength.

No default (Real) |

|

| T | Maximum pressure tensile strength. No default (Real) |

[Pa] |

| HEL | Hugoniot elastic limit. No default (Real) |

[Pa] |

| PHEL | Pressure at Hugoniot elastic limit. No default (Real) |

[Pa] |

| D1 | Damage constant. No default (Real) |

|

| D2 | Damage exponent. No default (Real) |

|

| K1 | Bulk modulus. No default (Real) |

[Pa] |

| K2 | Pressure coefficient. No default (Real) |

[Pa] |

| K3 | Pressure coefficient. No default (Real) |

[Pa] |

| BETA | Bulking pressure coefficient. No default (0.0 < Real <1.0) |

|

| NLKIN | Continuation line flag indicating that data input for kinematic hardening is to follow. 6, 13 | |

| TYPKIN | Kinematic hardening data input type.

|

|

| NKIN | Number of back stresses for kinematic

hardening definition via NLKIN. Default = 1 (Integer) |

|

| NLISO | Continuation line flag indicating that data input for isotropic hardening is to follow. 13 | |

| TYPISO | Isotropic hardening data input type.

|

|

| NISO | Number of parameters for isotropic

hardening definition via NLISO. Default = 1 (Integer) |

|

| SIGY0 | Initial yield stress via the

PARAM option for NLKIN or

NLISO. No default (Real > 0.0) |

|

| Ci | Parameter(s) Ci of

back stress components for NLKIN (PARAM). Up to

10 parameters (C1 to C10) can be specified. No default (Real > 0.0) |

|

| Gi | Parameter(s) Gi of

back stress components for NLKIN (PARAM). Up to

10 parameters (G1 to G10) can be

specified. No default (Real > 0.0) |

|

| Q | Parameter Q for

NLISO (PARAM). No default (Real > 0.0) |

|

| B | Parameter B for

NLISO (PARAM). No default (Real > 0.0) |

|

| SIG | Stress input for data curve input for

NLKIN (HALFCYCL) or NLISO

(TABLE). No default (Real > 0.0) |

|

| EPS | Equivalent plastic strain input for data

curve input for NLKIN (HALFCYCL) or

NLISO (TABLE). No default (Real > 0.0) |

|

| TEMP | Temperature for temperature-dependent

data specification for NLKIN or NLISO. No default (Real) |

|

| DAMAGE | Flag that identifies that the damage initiation and evolution criteria definition is to follow. 17 | |

| DMGINI_ID | ID of the DMGINI Bulk Data Entry. No default (Integer) |

|

| DMGEVO_ID | ID of the DMGEVO Bulk Data Entry. This is optional. Default = blank (Integer) |

|

| PFAIL | Percentage of failed integration points prior to element deletion.

Default = 1.0 (0 < Real < =1) |

Comments

- String based labels allow for easier visual identification, including when being referenced by other entries (example, the MID field of properties). For more details, refer to String Label Based Input File.

- For elastoplastic materials, the elastic

stress-strain matrix is computed from the MAT1 entry, and the isotropic

plasticity theory is used to perform the plastic analysis.

Either the table identification TID or the work hardening slope H may be specified, but not both.

- If TID is given,

TABLES1, TABLEG , TABLEST or

TABLEMD entries (Xi,Yi) of

stress-strain data (

x,Yx) must conform to the

following:

Entity TYPE = PLASTIC Quadrant Plastic stress-strain curve must be defined in the first quadrant only. First point If TYPSTRN = 0, - First point must be at the origin (X1=0, Y1=0).

- Second point (X2, Y2) must be the initial yield stress (Y2=LIMIT1) at initial yield strain (X2=LIMIT1/E).

The slope of the line joining the origin to the initial yield stress must be equal to the value of E.

If TYPSTRN=1,- First point (X1, Y1) is corresponding to initial yield stress (Y1=LIMIT1), with zero equivalent plastic strain (X1=0).

Additional details The data points must be in ascending order. If TYPSTRN=1,- TID may reference a TABLEST entry.

In this case, the above rules apply to all TABLES1 tables pointed to by TABLEST.

- In case of small deformations, the true and the engineering stress-strain curves are almost the same,so either of them can be used in the table definition.

- In case of large deformations, the true stress-strain curve should be used.

- If the deformations exceed the values defined in the table, linear extrapolation is performed.

- When TID refers to

TABLEMD, the following applies:

Xi_j Implicit Analysis (NLSTAT/Nonlinear Transient Analysis for SMDISP/LGDISP) Explicit Analysis Xi_1 Equivalent plastic strain. This can be used for both rate-dependent and independent problems. Represents plastic or total strain in case of rate-independent problems. Xi_2 Represents plastic strain rate in case of rate-dependent problems. If only one value of X2 is specified, it is still rate independent.

Represents plastic or total strain rate in case of rate-dependent problems. Xi_3 Temperature N/A - Information about rate dependent

plasticity:

Entity Implicit Analysis (NLSTAT/Nonlinear Transient Analysis for SMDISP/LGDISP) Explicit Analysis Activation Rate dependent plasticity can be activated by specifying TABLEMD ID in the TID field. This uses a piecewise linear function. Rate dependent plasticity can be activated in several ways. - Specifying TABLEMD ID in TID field. This uses a piecewise linear function.

- Johnson-Cook model (only when the strain rate is greater than RSTRT).

- Crushable Foam model.

- Cowper-Symonds model.

Elements Solid elements only. Shell and solid elements. Temperature dependent rate dependent plasticity Supported. The temperature-dependence is defined by referencing a TABLEST entry via the TID field. Not supported. TABLEMD definition A maximum of 4 fields can be used in TABLEMD, which represent, - Yield stress

- Equivalent plastic strain

- Plastic strain rate

- Temperature

Currently, only experimental data can be used. A stress-strain curve at zero plastic strain rate must be provided.

A maximum of three fields can be used in TABLEMD, which represent, - Yield stress

- Equivalent plastic strain

- Plastic/total/volumetric strain rate

Supported strain rates Only plastic strain rate is supported. Hence, total strain rate input (TYPSTRT=0) is ignored. Plastic/total/volumetric strain rate is supported. Additional remarks Total strain input (TYPSTRN=0) is not supported and ignored. The second column in TABLEMD must be the equivalent plastic strain.

Mixed hardening (HR=1, 2, 3 or real value) can be combined with rate dependent plasticity (TID=TABLEMD).

- Support information for kinematic and mixed

hardening:

Supported Entity Implicit Analysis (NLSTAT and Nonlinear Transient Analysis) Explicit Analysis Elements - SMDISP

- Shell (1st order) and solid elements

- LGDISP

- Shell (1st order) and Solid elements

Shell and solid elements - The conversion of the stress versus total

strain (TYPSTRN=0) into stress versus plastic strain

(TYPSTRN=1) is illustrated in Figure 1. This is

clearly different than simply shifting the entire table along the epsilon-axis.

Figure 1.

- Element support restrictions for

MATS1:

- Element Type

- Restriction

- Second order shell elements (CTRIA6 and CQUAD8)

-

- MATS1 is not supported

- CROD, CONROD, CBAR and CBEAM

-

- MATS1 is supported in the axial translational direction only

- The behaviors in other directions remain elastic. More specifically, the torsional deformation of the CROD/CONROD elements or the shear, bending and torsional deformations of the CBAR/CBEAM elements remain elastic.

- Information on the Johnson-Cook model:

- Entity

- Details

- Analysis type

- Supported only for Explicit Dynamic Analysis

- Strain rate dependency

- Activated only when strain rate is greater than reference strain rate

Johnson-Cook strain rate dependence assumes that

and for .

Where,- Yield stress for non-zero strain rate

- Equivalent plastic strain rate

- and

- Material parameters measured at or below the transition temperature

- Static yield stress

- Ratio of the yield stress at nonzero strain rate to the static yield stress

- Information on the Crushable Foam model:

- Entity

- Details

- Analysis type

- Supported only for Explicit Dynamic Analysis

- TSC definition

- Defined as a positive stress value which indicates the yield stress of crushable foam under tensile loading

- Table definition

- The yield stress of crushable foam under compression loading can be given by a

rate independent table (TABLES1) where the following rules apply:

- x values in the table are the volumetric strain (all positive values indicate that the volume is compressed). The volumetric strain is defined as .

- y values in the table are the compression

yield stress (all positive values).Note: Since crushable foam is based on volumetric strain-based definition, TYPSTRN=0 (default) is invalid and TYPSTRN=1 must be specified.

- First entry is x=0, y=y_0 (the initial compressive yield stress).

- All xi should be positive and in increasing order.

- Specific output

- Instead of the equivalent plastic strain, the integrated volumetric strain result (natural logarithm of the relative volume is output.

- Information on the Cowper-Symonds model:

- Entity

- Details

- Analysis type

- Supported only for Explicit Dynamic Analysis

- TYPSTRT

- Either total strain rate or plastic strain rate can be used

- Can be specified in linear hardening form or tabular form using TABLES1 or TABLEMD

The yield stress is computed as:

Where,- Reference rate plastic strain versus yield stress hardening function.

- Strain rate effect term, computed as .

- Information on using combined hardening:

- Entity

- Details

- Analysis type

- Supported only for Implicit Analysis (Nonlinear Static and Transient for SMDISP/LGDISP)

- Element type

- Supported only for solid elements

- Rate dependent plasticity with combined hardening

- Not supported, thus TID field is ignored

- Flexibility in combination

- Both NLKIN and NLISO support either parameter or stress-strain curve input.

At least one type of nonlinear hardening should be defined. For more information, refer to the Combined Hardening of von Mises Plasticity.

- Information on using NLKIN

or NLISO:

- Entity

- Details

- Analysis type

- Supported only for Implicit Analysis (NLSTAT/Nonlinear Transient Analysis for SMDISP/LGDISP)

- Temperature dependency

- When TYPKIN = HALFCYCL or TYPISO = TABLE, multiple curves can be provided one after each other. The last column temperature (TEMP) should be in ascending order. When TYPKIN/TYPISO = PARAM, the parameters can be temperature dependent, with TEMP specified in ascending order.

- Parameter fitting (for TABLE/HALFCYCL)

- The Levenberg-Marquardt method is used.

- Equivalent plastic strain determination

- For NLKIN, it is usually sourced directly from the first cycle of the experiment. For NLISO, it is usually sourced from cyclic loading experiments.

- Additional remarks

- If both NLKIN and NLISO use PARAM format, then the initial yield stress SIGY0 should be the same for the same temperature.

- When TYPKIN=PARAM, if the number of back stresses is equal to or greater than 4, multiple continuation lines can be used to define the complete set of parameters (C1-C10, G1-G10). See the example above.

- Temperature-dependent materials can be activated at the subcase level via different options (such as TEMP(MAT), TEMP(BOTH), DLOAD (via TLOAD1, TLOAD2 and TEMP/TEMPD Bulk Data Entries), etc.) depending on the subcase type.

- Temperature-dependent material can be activated at the subcase-level via different options (such as TEMP(MAT), TEMP(BOTH), DLOAD (via TLOAD# and TEMP/TEMPD Bulk Data Entries), and so on ...) depending on the subcase type. For more information, refer to Comment 2 on the TEMPERATURE Subcase Information Entry.

- The damage initiation and evolution failure

criteria can be defined using two methods:

- Using the DAMAGE continuation line in the MATS1 Bulk Data Entry. This method is supported both for Implicit and Explicit Dynamic Analysis.

- Using CRI=INIEVO in the MATF Bulk Data Entry. This method is supported only for Explicit Dynamic Analysis.

For more information, refer to Material Failure Criterion in the Explicit Dynamic Analysis section of the User Guide.

- The Johnson-Holmquist material model is

available to model brittle material behavior. It can be used with MAT1

elastic behavior and is currently only supported for solid elements. The shear modulus (

) and bulk modulus (

) can be used to input the corresponding Young's modulus and Poisson's ratio as:

The equivalent stress is the normalized Von Mises stress:

Where the normalizing stress is the Hugoniot elastic limit is calculated as:The normalized Von Mises stress, is compared to the normalized yield stress obtained with:

Where,- Intact material yield stress:

- Failed material yield stress:

If no damage parameters are specified , no plastic strain evolution is computed and an instant failure is obtained when the element behavior reaches the elastic limit. Otherwise, when damage parameters are mentioned, the plastic strain evolution is computed and the accumulated damage is:

Where the plastic strain to failure is calculated as:

The maximum pressure tensile strength is decreased during damage as:

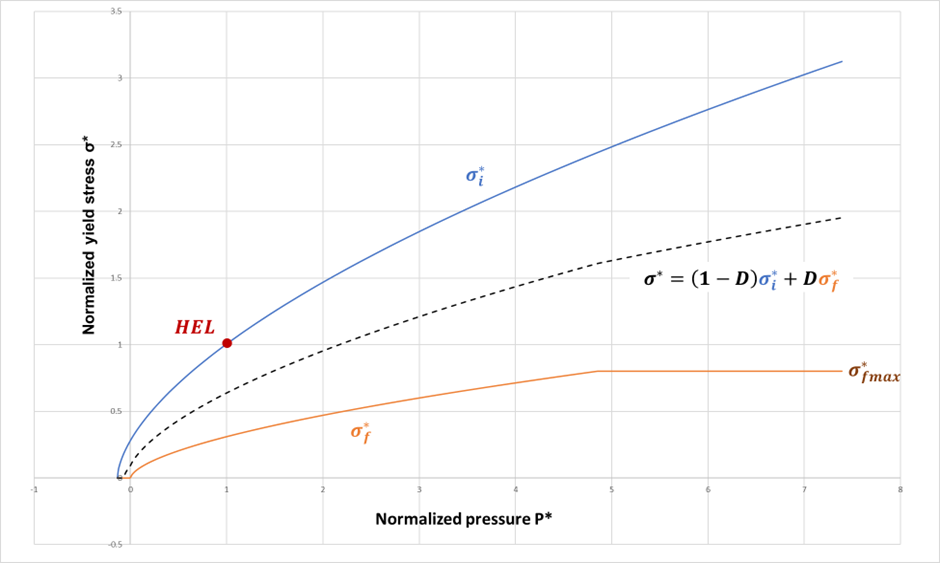

This allows a smoother transition between and during damage.Figure 2. Evolution of Normalized Yield Stress with Respect to Normalized Pressure. Damage value of D = 0.5.

The pressure is computed following an equation of state defined as:

in tension, andin compressionWhere:

When damage starts, a bulking pressure increment is computed as a function of elastic energy loss converted into potential hydrostatic energy:

Where , with .

This increment is then added to the equation of state described above:

- When some nonlinear material models which are currently only supported for explicit analysis, such as Johnson-Cook, Crushable Foam, Cowper-Symonds, and Johnson-Holmquist materials, are used for implicit analysis subcases, only the linear elastic part of these materials is considered for implicit analysis. A corresponding WARNING message is also printed to the .out file.