PFATSMW

Bulk Data Entry Defines properties for Seam Weld Fatigue Analysis.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| PFATSMW | ID | BRATIO | TREF | TREF_N | EVALDIS |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| ID | Each

PFATSMW card must have a unique ID. This

ID may be referenced from a FATDEF definition. No default (Integer > 0) |

|

| BRATIO | Critical bending

ratio. Default = 0.5 (Real > 0.0) |

|

| TREF | Reference thickness

for thickness effect consideration. 1 Default = 25.0 (Real > 0.0) |

|

| TREF_N | Exponent for the

thickness effect consideration. 1 Default = 0.2 (Real ≥ 0.0) |

|

| EVALDIS | Evaluation distance in

Joint Line method. 2

(Real ≥ 0.0) |

Comments

- TREF is used to define

the reference thickness for thickness effect consideration. If the thickness of

a shell (T) is greater than the specified value

(TREF), and the THCKCORR field on the

FATPARM entry is set to YES, then the

thickness effect is included by increasing the stress (

) based on:

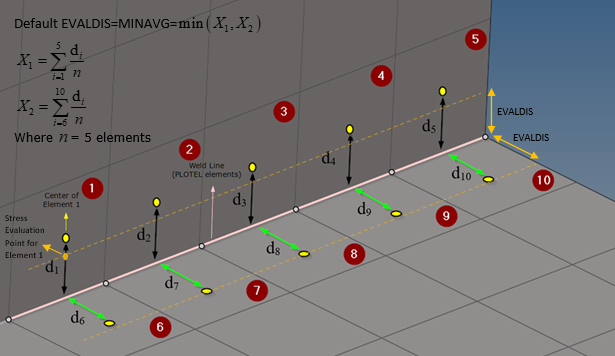

- The distance at which the stresses

are evaluated for a particular weld is defined by EVALDIS.

The stresses are actually evaluated at the element corners (based on STRESS

output request or PARAM,CNST4FAT), and then the stresses are

interpolated to the stress evaluation point (Figure 1) for each element. This stress

is used in further fatigue calculations.

Figure 1.