/MAT/LAW2 (PLAS_JOHNS)

Block Format Keyword This law represents an isotropic elasto-plastic material using the Johnson-Cook material model.

This model expresses material stress as a function of strain, strain rate and temperature. A built-in failure criterion based on the maximum plastic strain is available. For Solid and SPH elements, this material may account for the nonlinear dependence between pressure and density when corresponding Equation of State is prescribed.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW2/mat_ID/unit_ID or /MAT/PLAS_JOHNS/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | Iflag | VP | Pmin | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| a | b | n | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| UTS | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| c | ICC | Fsmooth | Fcut | Chard | |||||

| m | Tmelt | Tr | Tmax | ||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E | Young's modulus. (Real) |

|

| Poisson's ratio. (Real) |

||

| Iflag | Input type flag. 3

(Integer) |

|

| VP | Formulation for rate effects.

(Integer) |

|

| Pmin | Pressure cutoff (< 0). Default = -1020 (Real) |

|

| a | Yield stress. 2 (Real) |

|

| b | Plastic hardening parameter

b. (Real) |

|

| n | Plastic hardening exponent

n. 6

Default = 1.0 (Real) |

|

| Failure plastic strain. Default = 1020 (Real) |

||

| Maximum stress. Default = 1020 (Real) |

||

| Yield stress. (Real) |

||

| UTS | Ultimate tensile stress (engineering

stress). Input

. (Real) |

|

| Engineering strain at

UTS. Default = 1.0 (Real) |

||

| c | Strain rate coefficient

.

Default = 0.00 (Real) |

|

| Reference strain rate. If , no strain rate effect. (Real) |

||

| ICC | Strain rate computation flag. 9

(Integer) |

|

| Fsmooth | Strain rate smoothing flag.

(Integer) |

|

| Fcut | Cutoff frequency for strain rate

smoothing. Only available for shell and solid elements, Appendix: Filtering. Default = 1020 (Real) |

|

| Chard | Hardening coefficient (unloading).

(Real) |

|

| m | Temperature exponent. 13 Default = 1.00 (Real) |

|

| Tmelt | Melting temperature. Default = 1020 (Real) |

|

| Specific heat per unit volume. 11 (Real) |

||

| Tr | Reference temperature. 11 Default = 300 K (Real) |

|

| Tmax | Maximum temperature. Default = 1020 (Real) |

Example (Classic Parameter Input)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/PLAS_JOHNS/1/1

Steel

# RHO_I

7.8E-9

# E Nu Iflag flagVP Pmin

210000 .3 0 1 0

# a b n EPS_max SIG_max0

270 450.0 0.6 0 0

# c EPS_DOT_0 ICC Fsmooth F_cut Chard

0.10 1 0 0 0 0

# m T_melt rhoC_p T_r Tmax

0 0 0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Example (Simplified Input - Experimental Data)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/PLAS_JOHNS/1/1

Steel (use ultimate tensile stress(UTS) and engineering strain )

# RHO_I

7.8E-9

# E Nu Iflag flagVP Pmin

210000 .3 1 1 0

# SIG_y UTS EPS_UTS EPS_max SIG_max0

270 362.8 0.2885 0 0

# c EPS_DOT_0 ICC Fsmooth F_cut Chard

0.1 1 0 0 0 0

# m T_melt rhoC_p T_r Tmax

0 0 0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- This is an elasto-plastic material model that includes strain rate and temperature effects with true stress and strain output.

- In this model the material behaves as a

linear-elastic material when the equivalent stress is lower than the plastic yield stress.

For higher stress values, the material behavior is plastic, and the true stress is

calculated as:Where,

- Plastic strain

- Strain rate

- Temperature

- Tr

- Ambient temperature

- Tmelt

- Melting temperature

- If Iflag=0, the Johnson-Cook equation parameters a, b, and n values are

entered.

If Iflag=1, experimental engineering stress and stain data can be entered for , UTS and and the parameters a, b and n are calculated and printed in the Starter output file. If the a, b and n parameters cannot be automatically fit, then a Starter warning message will contain important information about changes to the material input.

- The plastic yield stress should always be greater than zero. To model pure elastic behavior, the plastic yield stress should be set to 1020.

- When

reaches the value of

in one integration point, then based on the element type:

- Shell elements: The corresponding shell element is deleted.

- Solid elements: The deviatoric stress of the corresponding integral point is permanently set to 0; however, the solid element is not deleted.

- The plastic hardening exponent, n must be less than or equal to 1.

- The strain rate has no effect on truss elements.

- To eliminate the effect of the strain rate, you can either set the value of c equal to 0 or the reference strain rate ( ) can be set equal to 1020. There is no effect of strain rate when is less than .

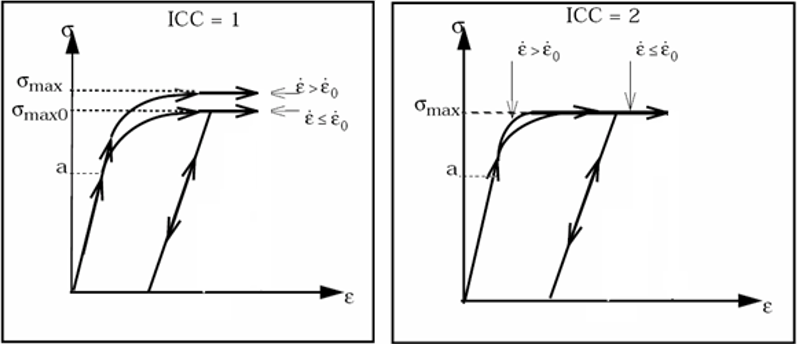

- The ICC flag defines the effect of strain

rate on the maximum material stress

. Figure 1 shows the value of for

the corresponding ICC flag.

Figure 1.

- There is no effect of temperature on trusses. Beam element (with /PROP/TYPE3 or /PROP/TYPE18) together with /HEAT/MAT or /THERM_STRESS/MAT could consider thermal effect.

- The temperature is constant ( ), if .

- Adiabatic conditions are assumed for

thermal simulations with initial temperature equal to reference temperature (Tr) and:

Where, is the plastic energy increment with .

- The strain rate coefficient, c and reference strain rate must be defined to include thermal effects.

- When /HEAT/MAT (with Iform=1) references this material model, the values of Tr, Tmelt and defined in this card will be overwritten by the corresponding , and defined in /HEAT/MAT.

- When the temperature is not initialized using /HEAT/MAT or /INITEMP, the reference temperature (Tr) is also the initial temperature.

- The hardening coefficient is used to describe the hardening model (during unloading). The values of the hardening coefficient should be between 0 and 1.

- By default, the hydrostatic pressure is linearly proportional to the

density:Where,

- Bulk modulus

An additional Equation of State (/EOS) card can refer to this material in order to define a nonlinear dependency between hydrostatic pressure and volumetric strain.

This behavior is only available for solid and SPH elements.