/MAT/LAW104 (JOHNS_VOCE_DRUCKER)

Block Format Keyword An elasto-plastic constitutive material law using the 6th order Drucker model with a mixed Voce and linear hardening. Dependence on the Johnson-Cook strain rate and thermal softening effects due to self-heating can also be modeled. The law is available for isotropic shell and solid elements.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW104/mat_ID/unit_ID or /MAT/JOHNS_VOCE_DRUCKER/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | Ires | ||||||||

| H | Q | B | CDR | ||||||

| CJC | Fcut | ||||||||

| Tref | Tini | ||||||||

| Cp | |||||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Optional unit

identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| E | Young‘s

modulus. (Real) |

|

| Poisson’s

ratio. (Real) |

||

| Ires | Resolution method for plasticity.

(Integer) |

|

| Initial yield

stress. (Real) |

||

| H | Linear hardening

module. (Real) |

|

| Q | Voce hardening

coefficient. (Real) |

|

| B | Voce hardening

exponent. (Real) |

|

| CDR | Drcker

coefficient. (Real) |

|

| CJC | Johnson-Cook strain rate

coefficient. (Real) |

|

| Inviscid limit for the plastic

strain rate. (Real) |

||

| Fcut | Plastic strain rate filtering

frequency, Default = 10 kHz (Real) |

|

| Temperature softening

slope. (Real) |

||

| Tref | Reference temperature at which the

hardening law was identified in experiment. (Real) |

|

| Tini | Initial temperature of material in

simulation. (Real) |

|

| Taylor-Quinney

coefficient. (Real) |

||

| Cp | Specific heat. (Real) |

. |

| Plastic strain rate at isothermic

conditions. (Real) |

||

| Plastic strain rate at adiabatic

conditions. (Real) |

Comments

- The law uses 6th

order Drucker equivalent stress definition:

(1) Where , are respectively the second and third invariant of the deviatoric stress tensor .

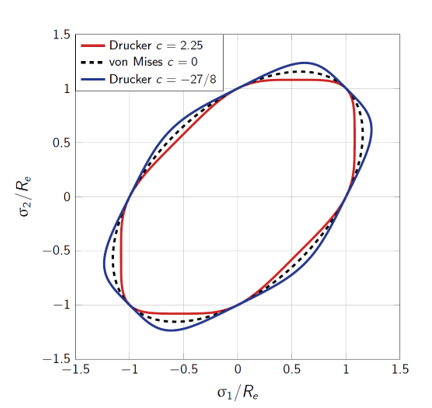

The parameter is user-defined and allows to define several yield surfaces (Figure 1). To respect the convexity, its value must respect -27/8 ≤ CDR ≤ 2.25.

Figure 1. Drucker yield surfaces - The yield function is

defined as:

(2) and(3) Where,- Initial yield stress.

- H

- Linear hardening.

- Voce hardening parameters.

- Johnson-Cook strain rate coefficient.

- Filtered plastic strain-rate.

- Inviscid limit plastic strain rate.

- Thermal softening slope.

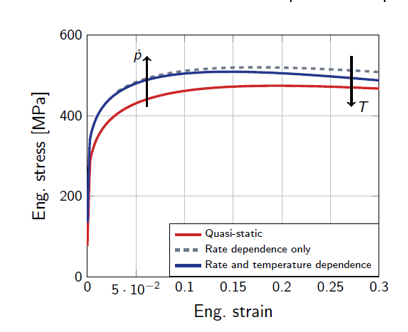

The evolution of this flow stress equation with plasticity.

Figure 2. Flow stress evolution with plasticity - If

/HEAT/MAT is not used for this material, the

temperature is calculated internally using the incremental

formula:

(4) Where,- Plastic work increment.

- Taylor-Quinney coefficient that must respect .

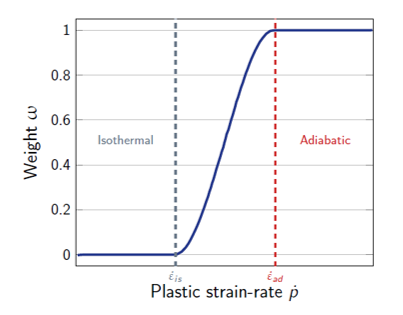

- Coefficient that defines the transition between isothermal and adiabatic conditions (Figure 3).

(5)

Figure 3. Evolution of the temperature weight with the plastic strain rate