/MAT/LAW78

Block Format Keyword This law is the Yoshida-Uemori model for describing the large-strain cyclic plasticity of metals. The law is based on the framework of two surfaces theory: the yielding surface and the bounding surface.

During the plastic deformation, a yield surface will move within the bounding surface and will never change its size, and the bounding surface can change both in size and location. The plastic-strain dependency of the Young's modulus and the work-hardening stagnation effect are also taken into account. Concerning SPH, it is compatible with solid only, this can be verified with the /SPH/WavesCompression test. The solid version is only isotropic. The shell version is anisotropic based on Hill criterion.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW78/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | |||||||||

| Y | b | h | B0 | ||||||

| m | Rsat | OptR | C1 | C2 | |||||

| r00 | r45 | r90 | Mexp | Icrit | |||||

| fct_IDE | Einf | CE | |||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E | Young's modulus. (Real) |

|

| Poisson's ratio. (Real) |

||

| Y | Yield stress. (Real) |

|

| b | Center of the bounding

surface. (Real) |

|

| Parameter for kinematic hardening rule

of yield surface (or used in calculation of

if

). 5 (Real) |

||

| h | Material parameter for controlling work

hardening stagnation. (Real) |

|

| B0 | Initial size of the bounding

surface. (Real) |

|

| m | Parameter for isotropic and kinematic

hardening of the bounding surface. (Real) |

|

| Rsat | Saturated value of the isotropic

hardening stress. (Real) |

|

| OptR | Modified isotropic hardening rule flag

(available for shells only):

(Integer) |

|

| C1, C2 | Constant used in the modified

formulation of the isotropic hardening of bounding surface (available for shells

only). (Real) |

|

| r00 | Lankford parameter (0 degree) used for

shell elements. Default = 1.0 (Real) |

|

| r45 | Lankford parameter (45 degree) used for

shell elements. Default = 1.0 (Real) |

|

| r90 | Lankford parameter (90 degree) used for

shell elements. Default = 1.0 (Real) |

|

| Mexp | Exponent

in Barlat's 1989 Yield Criterion for shell elements.

See Comment 8.

(Real) |

|

| Icrit | Plastic criterion selection flag.

|

|

| fct_IDE | ID of the function defining the scale

factor of Young's modulus evolution versus effective plastic strain. 9 (Integer) |

|

| Einf | Asymptotic value of Young's

modulus. (Real) |

|

| CE | Parameter controlling the dependency of

Young's modulus on the effective plastic strain. (Real) |

|

| Parameter

for kinematic hardening rule of yield surface. 5

Ignore if . (Real) |

Example

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW78/1/1

DP600-HDG

# RHO_I

7.8E-9

# E NU

206000 .3

# Y B C2KH H B0

420 112 200 0 555

# m RSAT OPTR C1 C2

12 190 0 1 1

# R0 R45 R90 Mexp Icrit

1 1 1

# Fct_IDE EINF CE C1KH

0 163000 50 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- For solid elements, von Mises yield criterion is

used, so the yield function is expressed as:

(1) Whereas for shell elements, Hill’s (1948) or Barlat’s (1989) yield criterion are used, which allows for the modeling of anisotropic materials:- The Hill’s criterion is expressed as:

(2) Where,- Yield stress.

- Total back stress.

If , then is expressed as:(3) - The Barlat’s criterion is expressed as:

(4) Where, is the exponent in Barlat's yield criterion.

is expressed as:(5) With,

and .

Parameters , , and are computed from the Lankford coefficients.

, ,

Parameter is obtained by solving:(6)

- The Hill’s criterion is expressed as:

- Yield stress, Poisson ratio and Young's modulus should be strictly positive. The other parameters should be non-negative value.

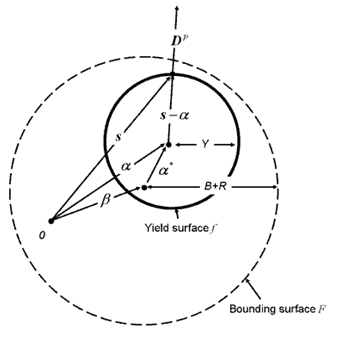

- The schematic illustration of the

two-surface model is shown in Figure 1.

Where, 0 is the original center of the yield surface, the yield surface with its center and its radii Y, is moving kinematically, within a bounding surface that has a size indicated by B+R and tensor indicating its center position.

Figure 1. Schematic Drawing of the Two-surface Model - The yield surface is subjected to a kinematic

hardening. The kinematic motion is described by

that has the following evolution:

- for shell elements

(7) - for solid elements

(8)

Where,- Equivalent plastic strain rate

- C and a

- Material parameters and

- Total back stress

Note: In case of a quadratic (using Hill or =2.0 with Barlat) and isotropic criterion ( ), the shell kinematic motion equation equals the solid one. - for shell elements

- The parameter

for kinematic hardening rule can take two different values

to describe a change of work hardening rate for forward and reverse deformations.

- If ,

- If , the change of work hardening rate is deactivated and .

- The bounding surface is subjected to an

isotropic-kinematic hardening. The evolution equation for isotropic hardening is:

- Default (if OptR = 0) Yoshida expression

- Available for shell elements, if OptR = 1

The evolution equation for kinematic hardening of bounding surface is:- for shell elements:

(9) - for solid elements:

(10)

Note: In case of a quadratic (using Hill or Mexp=2 with Barlat) and isotropic criterion ( ), the shell kinematic hardening equation equals the solid one. - The work-hardening stagnation during unloading is

described using a J2-type surface

with a radius r and a center

q:

(11) Where,- Denotes a material parameter that determines the rate of expansion of surface .

- Should be either inside or on the surface .

- The exponent in Barlat’s (1989) yield

criterion can be set by considering the microstructure of the material. Any value greater

than 2.0 is valid, but typically:

- Mexp = 6.0 (Default) for a Body Centered Cubic (BCC) material

- Mexp = 8.0 for a Face Centered Cubic (FCC) material

- The evolution of Young's modulus:

- If fct_IDE > 0, the curve defines a scale factor for Young's modulus

evolution with equivalent plastic strain, which means the Young's modulus is scaled by

the function

:

The initial value of the scale factor should be equal to 1 and it decreases.

-

If fct_IDE = 0, the Young's modulus is calculated as:

(12) Where,- E and Einf

- Initial and asymptotic value of Young's modulus, respectively.

- Accumulated equivalent plastic strain.

Note: If fct_IDE = 0 and CE = 0, Young's modulus E is kept constant.

- If fct_IDE > 0, the curve defines a scale factor for Young's modulus

evolution with equivalent plastic strain, which means the Young's modulus is scaled by

the function

:

- This material law is not available for implicit analysis.