/MAT/LAW115 (DESHFLECK)

Block Format Keyword An elasto-plastic constitutive law using von Mises criterion with pressure dependence. The hardening law is linear – nonlinear with an increasing exponential hardening.

Parameters can either be constant over all element of the part or can be statistically distributed over the elements. This introduces a probabilistic approach in the results of the simulation.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW115/mat_ID/unit_ID or /MAT/DESHFLACK/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | Ires | Istat | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Optional: Unit

identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| E | Young‘s

modulus. (Real) |

|

| Poisson's

ratio. (Real) |

||

| Ires | Resolution method for plasticity.

(Integer) |

|

| Istat | Activate statistical variation

flag.

(Integer) |

|

| Yield surface shape

parameter. Default = 0.0 (Real) |

||

| Linear hardening modulus. Default = 0.0 (Real) |

||

| Densification strain. Default = 1.0E20 (Real) |

||

| Nonlinear hardening

modulus. Default = 0.0 (Real) |

||

| Nonlinear hardening

parameter. Default = 1.0 (Real) |

||

| Initial flow stress. Default = 1.0E20 (Real) |

||

| Tensile volumic plastic strain at

failure. Default = 0.0 (Real) |

||

| Maximum principal stress at

failure. Default = 0.0 (Real) |

||

| Density of base material (matrix

material of the foam). Default = 1.0E20 (Real) |

||

| , | Statistical law parameters for

initial flow stress. (Real) |

|

| , | Statistical law parameters for

nonlinear hardening modulus. (Real) |

|

| , | Statistical law parameters for

linear hardening modulus. (Real) |

|

| , | Statistical law parameters for

nonlinear hardening exponent inverse. (Real) |

|

| Statistical law exponent of the

parameter. (Real) |

Example (Aluminum)

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/25

Local unit system

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW115/1/25

Aluminum foam constant

# Init. dens.

5.1E-10

# E Nu Ires Istat

5562.0 0.3 2 0

# ALPHA EPSVP_F SIGP_F

2.12 0.11 32.1

# SIGP GAMMA EPSD ALPHA2 BETA

14.82 5.37 1.67 66.9 2.99

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddataExample (Random Noise/Distribution)

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/25

Local unit system

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/DESHFLECK/1/25

Aluminum foam statistical

# Init. dens.

5.1E-10

# E Nu Ires Istat

5562.0 0.3 1 1

# ALPHA EPSVP_F SIGP_F RHOF0

2.12 0.11 30.0 2.7E-9

# SIGP_C0 SIGP_C1 SIGP_N

0 590.0 2.21

# ALPHA2_C0 ALPHA2_C1 ALPHA2_N

0 140.0 0.45

# GAMMA_C0 GAMMA_C1 GAMMA_N

0 40.0 1.4

# INV_BETA_C0 INV_BETA_C1 INV_BETA_N

0.22 320.0 4.66

/PERTURB/PART/SOLID/1

set Random Noise with random distribution on Solid density

# Mean_value Deviation Min_cut Max_cut Seed Idistri

1.0 0.02471 0.6 1.4 1000 2

#grpart_ID parameter

46 DENS

/GRPART/PART/46

part

1

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddataComments

- The material is supposed to be isotropic linear elastic.

- The law uses the

Deshpande-Fleck equivalent stress definition:

(1) Where,- The von Mises equivalent stress.

- The mean stress defined by:

(2)

The parameter controls the effect of pressure dependence in the computation of equivalent stress. This parameter must respect the following inequality:(3) - The yield

function is denoted

, compared to the Deshpande-Fleck equivalent

stress to the flow stress,

:

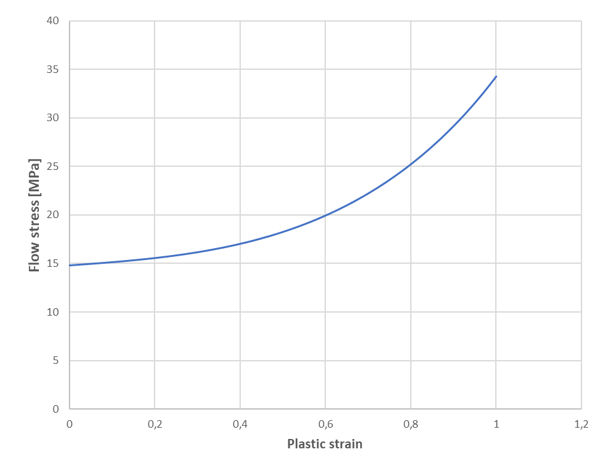

(4) With the flow stress defined by (Figure 1):(5) Where,- Initial flow stress.

- Linear hardening modulus.

- Densification strain.

- Nonlinear hardening modulus.

- Nonlinear hardening exponent.

Figure 1. Flow stress evolution with plastic strain - Two versions of

the same material are available, depending on the value of the flag

Istat:

- If Istat = 0: parameters , , , and are the same for all solid elements of the part.

- If

Istat =

1: parameters

,

,

,

and

are not the same for all solid elements of

the part.They are computed from the foam density that is statistically distributed (using /PERTURB/PART/SOLID).

(6) Where,- , , and

- Statistical law parameters.

- Base material density (for instance, if the material law represents aluminum foam, will be aluminum density).

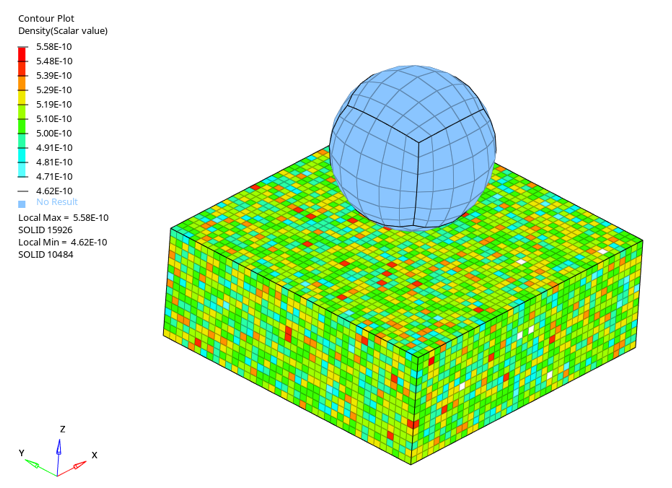

- When using

Istat =

1, the card /PERTURB/PART/SOLID must

be set to create the initial foam density

distribution over all elements of the part (Figure 2).

Figure 2. Example: foam density distribution in a foam block for an impact simulation - Most failure criteria are compatible with /MAT/LAW115; however, element deletion can be onset by you, if and/or are different from 0. The element deletion will be onset if the tensile volumetric strain is higher than and/or, if the first principal stress is higher than .