/MAT/LAW65 (ELASTOMER)

Block Format Keyword This law describes nonlinear elastoplastic material with strain rate dependent loading and unloading behavior.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW65/mat_ID/unit_ID or /MAT/ELASTOMER/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | |||||||||

| Nrate | Fsmooth | Fcut | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_IDld | fct_IDul | Fscalestress | |||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material

title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| E | Young's

modulus. (Real) |

|

| Poisson's

ratio. (Real) |

||

| Failure plastic

strain. (Real) |

||

| Nrate | Number of

loading/unloading function pair. Default = 50 (Integer) |

|

| Fsmooth | Smooth strain rate flag.

(Integer) |

|

| Fcut | Cutoff frequency for

strain rate filtering. Default = 1030 (Real) |

|

| fct_IDld | True stress-true strain

function identifier for loading. (Integer) |

|

| fct_IDul | True stress-true strain

function identifier for unloading. (Integer) |

|

| Fscalestress | Stress scale

factor. Default = 1.0 (Real) |

|

| Strain rate. Default = 1.0 (Real) |

Example (Nitinol)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW65/1/1

nitinol-like material

# RHO_I

6E-6

# E0 NU EPS_max

50 .3 0

# Nrate Fsmooth Fcut

1 1 0

#FUNC_IDld FUNC_IDul FSCALESTRESS EPS_rate

3 4 1 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 3. FUNCTIONS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/3

Loading_stress_strain

# X Y

0 0

.0085 .35

.0575 .55

.077 1.262

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/4

Unloading_stress_strain

# X Y

0 0

.0055 .199

.0502 .25

.077 1.245

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

Comments

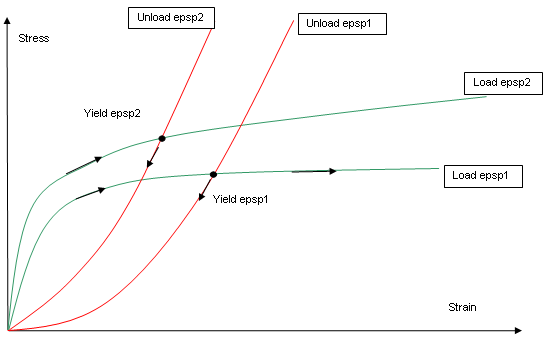

- The law is defined by pairs of true stress-true strain functions for loading and unloading at specified strain rates. Each of the curves should begin with point (0,0) and increase monotonically. Each unloading curve should lie below the loading curve for corresponding strain rate.

- The loading/unloading curve with the higher strain rate ( ) should lie above the curve with lower strain rate ( ). The curves between and are interpolated linearly for intermediate strain rates. Curves are extrapolated for strain rates higher than maximum specified strain rate. It is advised to duplicate the last curves twice to avoid instability for high strain rates.

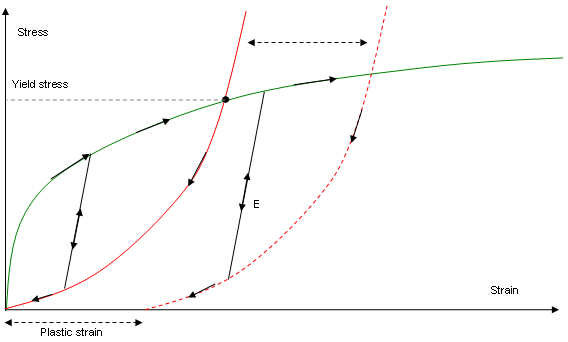

- Yield stress is determined at the intersection point between loading and unloading curves.

- If the load is removed

prior to the intersection point between loading and unloading curves, the

unloading follows the hyperelastic path with hysteresis (Fig. 1). This path is calculated based on the value of Young's

modulus, E until it intersects with the unloading curve.

Thereafter it follows the unloading curve back to its initial state (0,0).

If the load is removed after intersection point between loading and unloading curves, the unloading curve is shifted by the value of plastic strain (Fig. 2).

- The Young's modulus must be greater than the maximum slope of all stress-strain curves. As mentioned before, Young's modulus is used to determine the unloading path between loading and unloading curves.

- When

reaches

in one integration point, then based on the element

type:

- Shell elements:

The corresponding shell element is deleted.

- Solid elements:

The deviatoric stress of the corresponding integral point is permanently set to 0, however, the solid element is not deleted.

Figure 1. Loading and Unloading Function Sets for Constant Strain Rates - Hyperelastic Loading/Unloading

Figure 2. For Plastic Case the Unloading Curve is Shifted by the Value of the Actual Plastic Strain - Shell elements: