Vent

![]()

Description

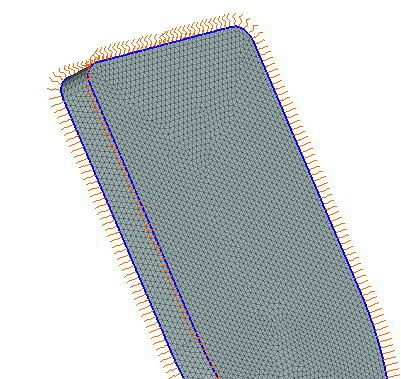

Vents in the mold allow the trapped air inside the mold cavity to escape during the filling process. Choosing the correct venting location is critical for successful filling. Vents are machined in the mold and these are very small in size (in the order of microns). They are designed to vent the air and not let the resin leak. The default value of vent exit pressure (gauge) is 0. In this release, vacuum conditions are not supported. Hence, the value 0 is always correct. Solver support three different options for venting.

- Using 1D lines. This is the preferred option.

- Using 2D surface elements. This is largely used for testing and validation examples.

- Automatic venting. This happens when the user does not define any vent. This

option is not preferred.

Vent BC is relevant only for the filling analysis and is not used for packing or cooling analysis. Hence, you will find this Dirichlet BC in the BC file for filling. Solver automatically closes a vent after the resin has reached this location.

Steps

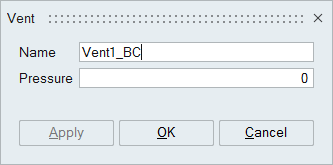

- Specify name of Vent BC. Use pressure = 0.

- Select mesh edge from body. Once all vent edges are selected, click on OK

button.