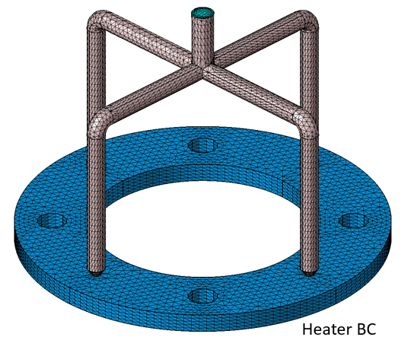

Hot Runner Systems - Heater BC

![]()

Description

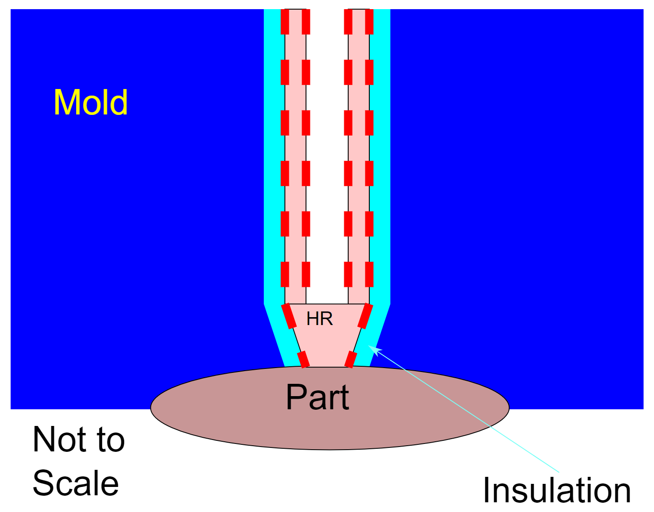

Polymer melt is maintained at inlet temperature in a hot runner system throughout the cycle in the filling, packing, and cooling phases.

To accomplish this variety of techniques are used. This BC enables us to specify these conditions. Three different heater controls can be applied.

On each hot runner surface, one of these conditions is applied.

- Insulated

- Temperature Control

- Heater Control

Insulated Condition

In this condition, Heat Flux = 0 is applied. In addition, a leakage condition is applied.

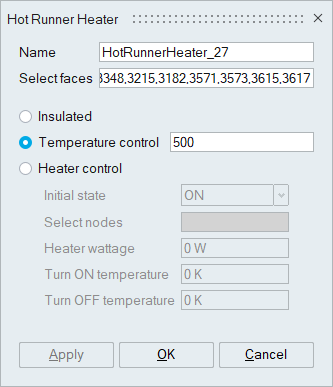

Temperature Control

In this condition, a constant temperature T=Specified Value is applied. In a machine, this may be achieved by closed-loop feedback control. However, in the solver, it is an idealistic condition of constant temperature is imposed. A more realistic BC is the heater control BC.

Heater Control

In this BC, the heater is turned on and off based on thermocouple in sensor nodes.

- Initial state

Initial state of the heater can be on or off

- Select nodes

Select the sensor nodes that will be used to determine if the heat should be turned off on on

- Heater Wattage (W)

This wattage will be divided by the surface area and heat flux (W/m2) is applied

- Turn ON temperature

When any one of the sensor nodes drops below the turn-on temperature, the heater will be turned on.

- Turn OFF temperature

When all of the sensor nodes increase above the turn-off temperature, the heater will be turned off.

Leakage HTC

Even though the heater surfaces are insulated, there will always be some heat leakage to the mold. In this version, there is no user control for this data. Solver applies a standard leakage of leakage HTC=25 W/m2-K and average mold temperature = 350 K. This data will be exposed in the next release.