Hot Runner Systems

![]()

Introduction

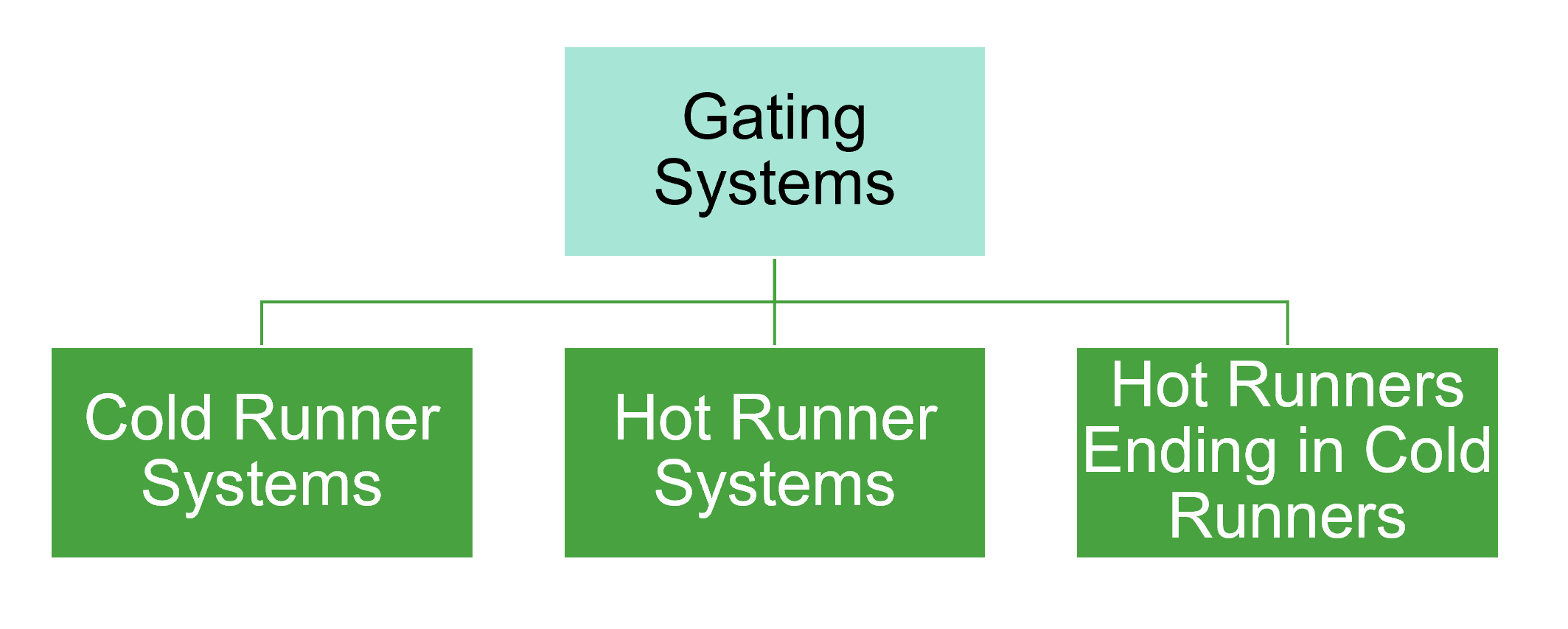

SimLab supports creating a variety of hot and cold runner system setup. Around 35% of the injection molded parts use hot runner systems and SimLab provides all the necessary controls to models these combinations.

Hot and Cold Runner System Differences

IHot

- Polymer in the hot runner stays in the melt state (as a liquid) throughout the cycle

- Material in the runner is not ejected

- Results in saving of material and cycle time

- Polymer solidifies during cooling

- Material in the runner is ejected along with the part

- Results in material wastage and increase cycle time

- Mold costs are cheaper

Modeling Hot Runner Systems

Modeling involves

SimLab can also setup models with thermally controlled (open) gate systems.