Overview of Simulation Results

List of contour plots

List of all available contour plots from injection molding solver.

- Air Traps

- Density

- Fill Time

- Pressure

- Temperature

- Velocity

- Maximum Velocity

- Strain Rate

- Weld Surface

- Viscosity

- Sink Marks

- Fiber Orientation Tensor

- Warpage - Displacement

- Warpage - Stresses

Air Traps

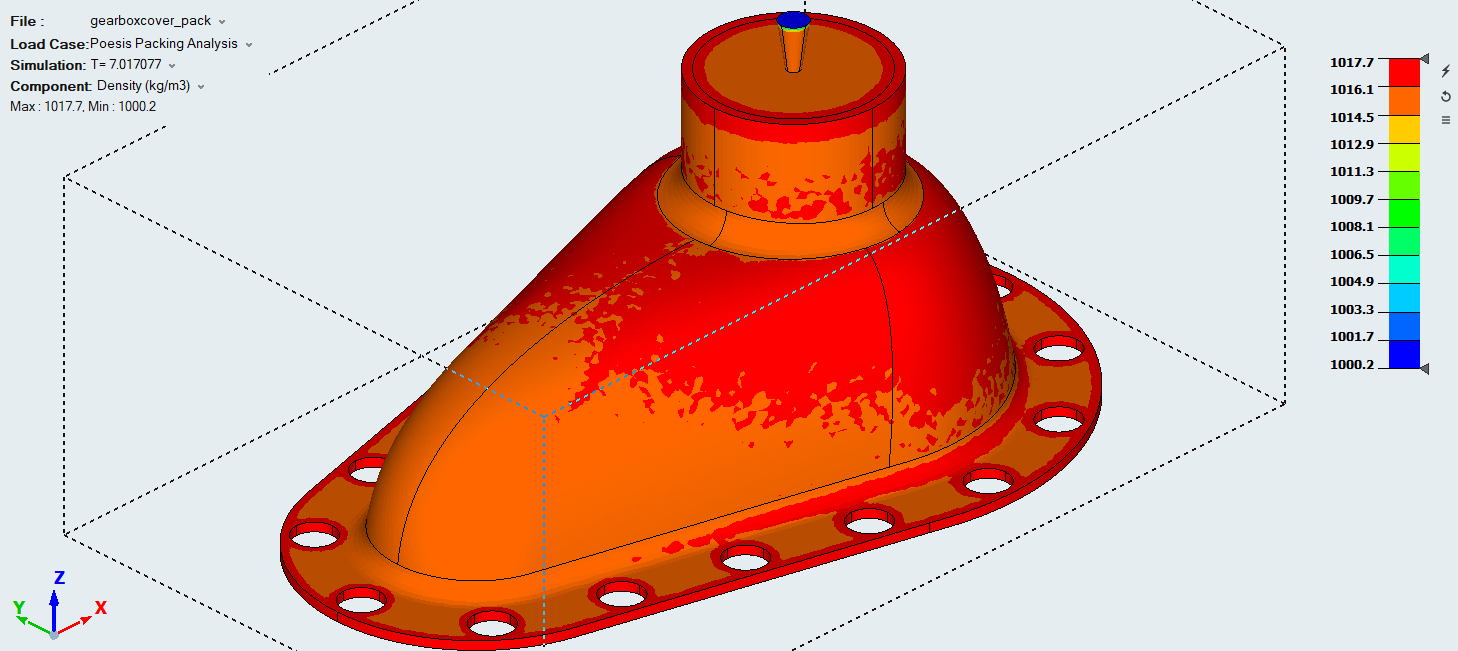

This contour help visualize the position of air pockets in the molding process. Different flow patterns cause a wide variety of air trap results, and filling simulation enables you to adjust venting designs to avoid such problems.Density

Polymer density depends on temperature and pressure. Injection molding solver computes density during packing and cooling stage. Uniform density will lead to a good quality part with less warpage distortion.

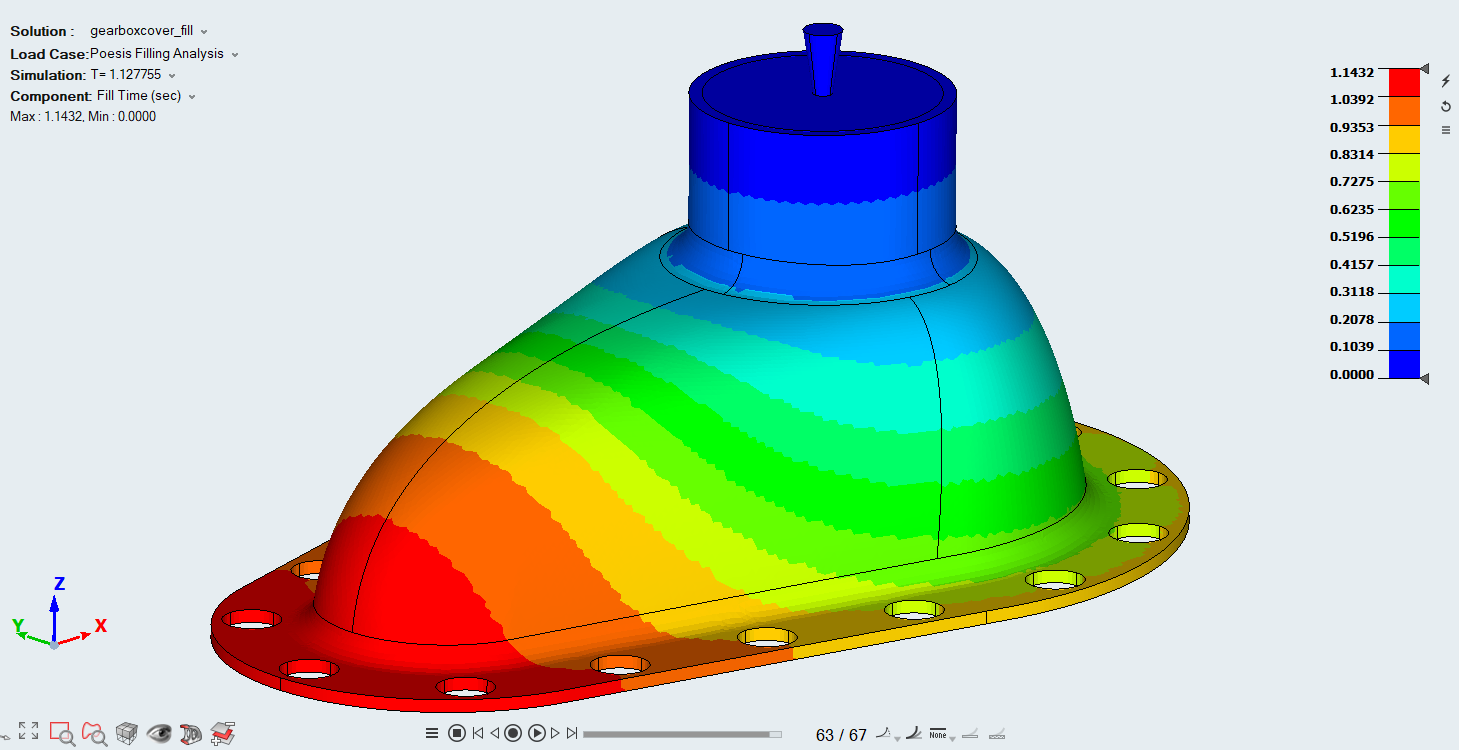

Fill Time

- potential incomplete filling,

- unbalanced flow,

- identify weld line,

- air pockets regions

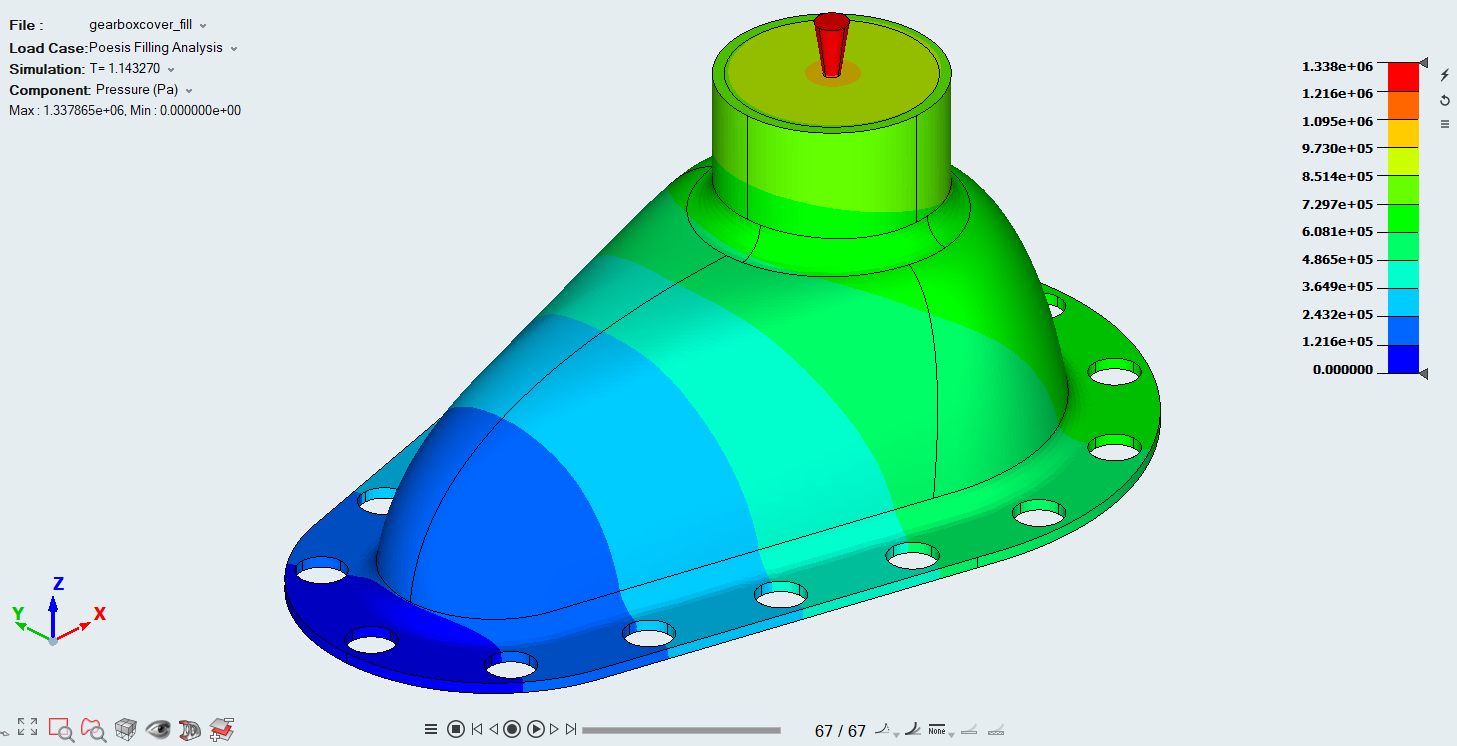

Pressure

- High injection pressure can lead to overflowing and flash

- Low injection pressures can lead to Air bubbles and voids

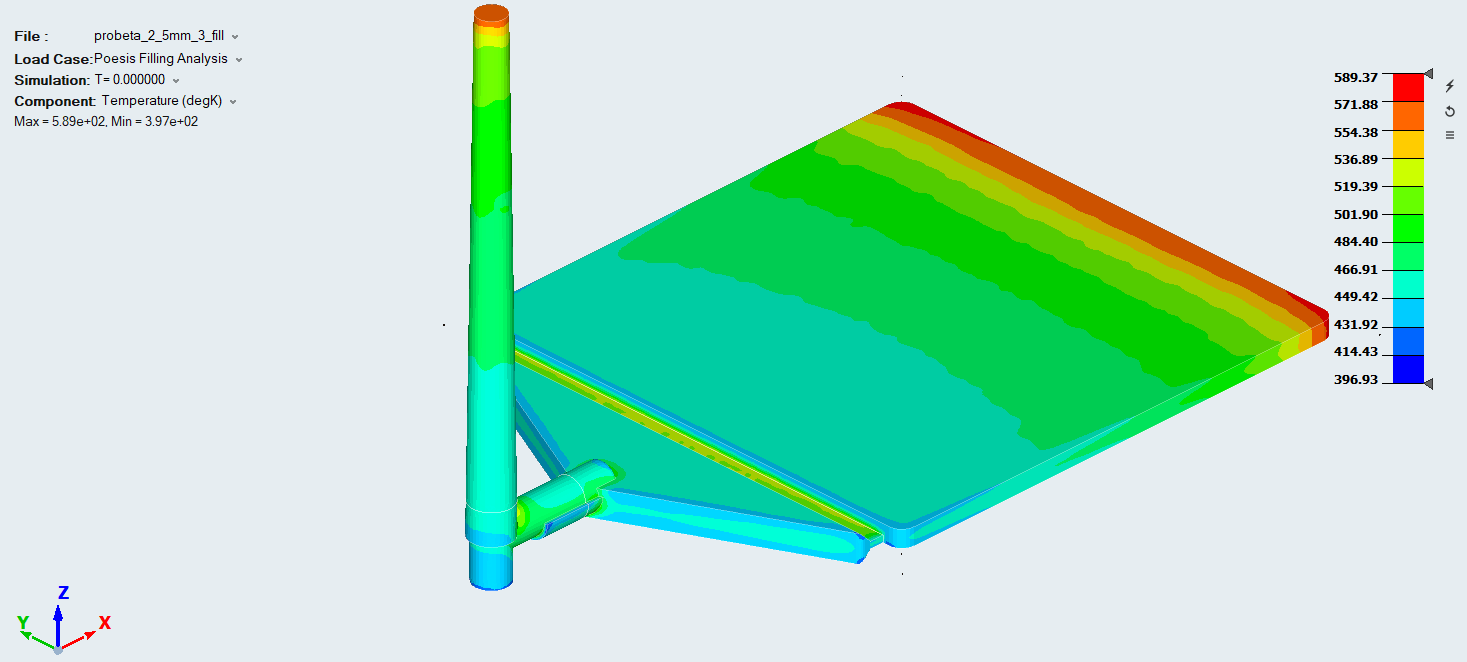

Temperature

- Determine how the melt-front temperature evolves as it reaches each region in the mold cavity.

- Determine how heat is conveyed and dissipated in the molding process.

- Check region of excessive heating or cooling, and to determine the appropriate fill speed for uniform temperature distribution.

- Injection molding solver simulates combined effects of viscous heating of polymer melt and mold cooling across the part thickness during the entire injection process.

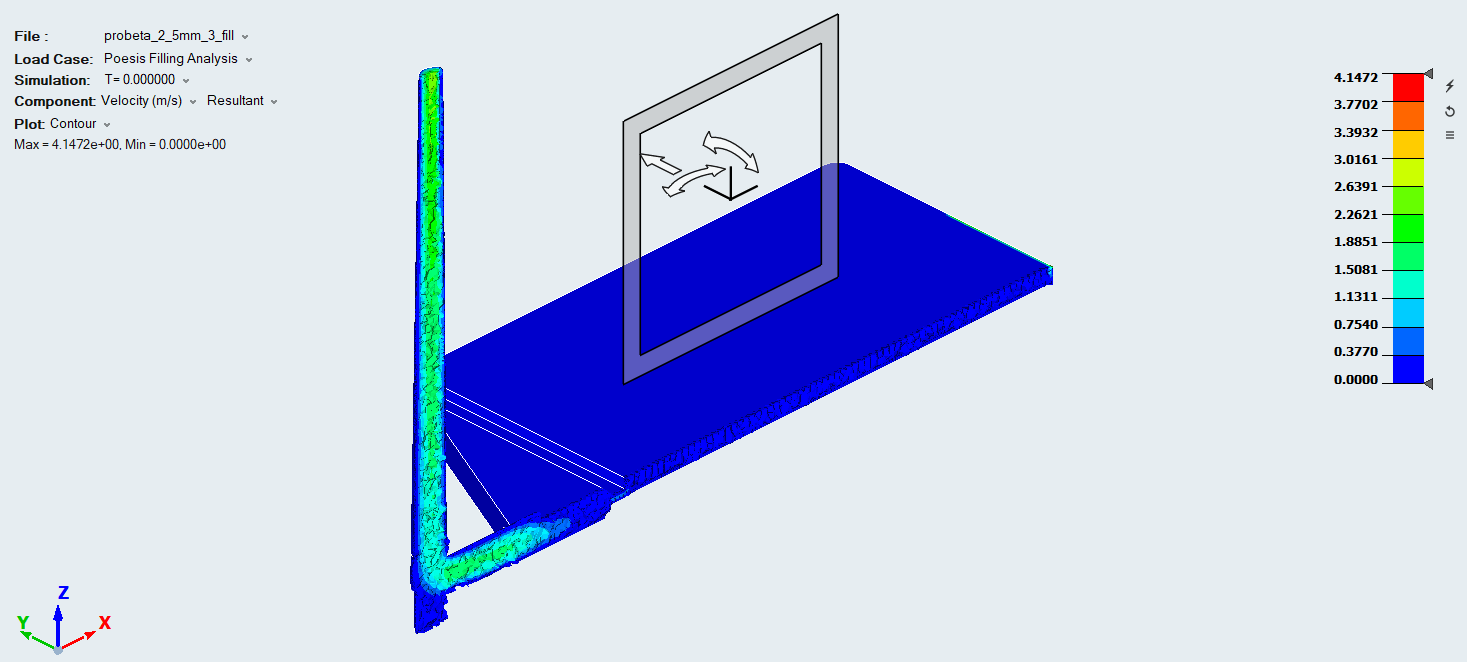

Velocity

This data provides a detailed understanding of how a material deforms and flows during the molding process. Using this data, we can determine if the mold cavity is filling uniformly or not. For multi-cavity mold, it is important that velocity at the gate is within the desired value to avoid non-uniform filling. By studying the material flow in the runner system, mold cavity, it can be redesign to improve the performance.

Maximum Velocity

This data provides maximum speed achieved by polymer melt during filling of the mold cavity.Strain Rate

Strain rate is an important factor in design runner system, mold cavity, and process data. Higher strain rate will lead to degradation of the polymer and poor quality molded parts. This generally happens near the wall and gate.

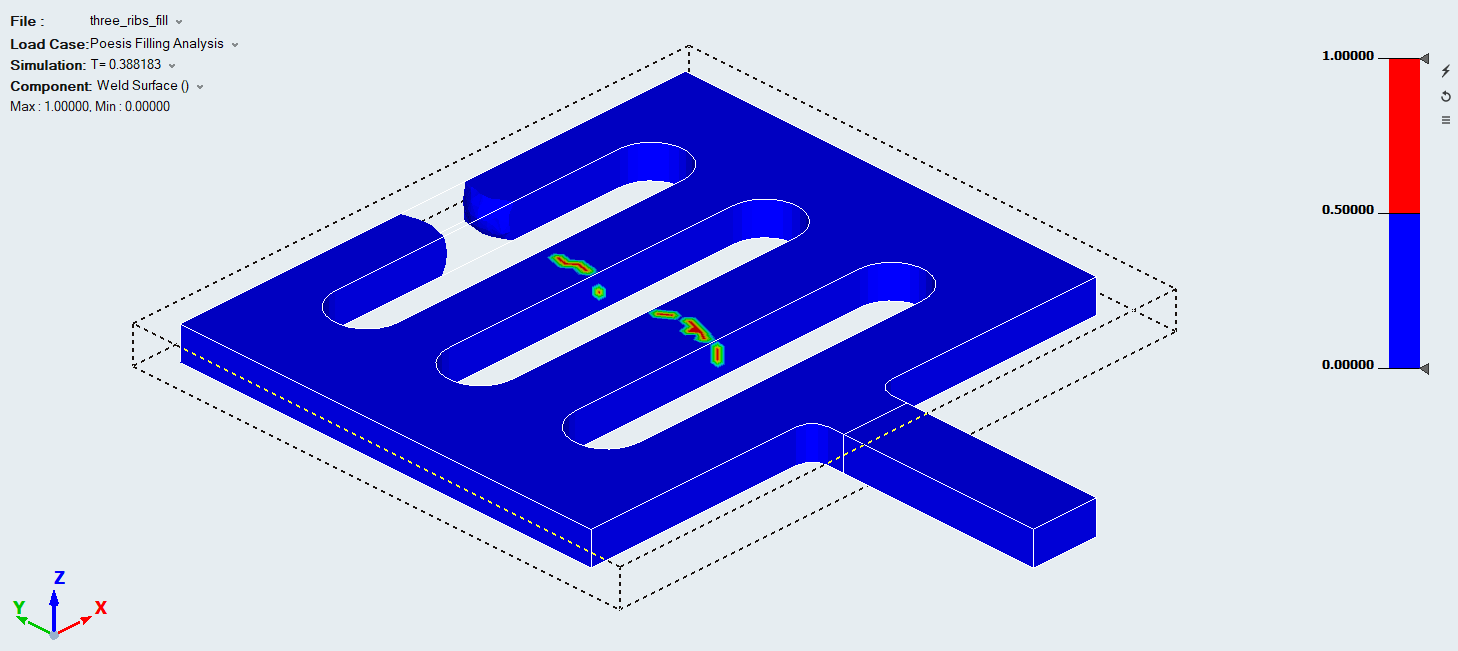

Weld Surface

Weld lines are regions where two or more streams of polymer merge. Different flow patterns lead to a wide variety of weld-lines, which can cause cosmetic blemishes or structural issues. With Injection Mold Solver, we can observe possible weld regions and correct gate locations. The contour values are between 0 and 1. Value 1 represents the weld surface region.

Viscosity

Based on material data, local temperature and shear rate, the effective viscosity of polymer melt is computed to visualize its distribution.

High viscosity regions will need more pressure to drag polymer.

Check if high shear rate tends to cause war-page the part

Sink Marks

Even after the part is 100% filled, there are post filling defects like sink mark, tolerance issues due to shrinkage of the polymer melt. By holding the inlet pressure more material is packed into the mold cavity to overcome such defect.

Sink marks occur in parts with varying thicknesses. The greater the differences in the thicknesses, the more the sink marks. Changing injection molding parameters, or design can reduce sinking to an acceptable level.

Fiber Orientation Tensor

Fiber orientation analysis predicts the fiber orientation tensor for short fiber reinforced polymers. Solver writes fiber orientation tensor in result file and ASCII files that can be imported into Multiscale Designer for further strength/failure analysis.

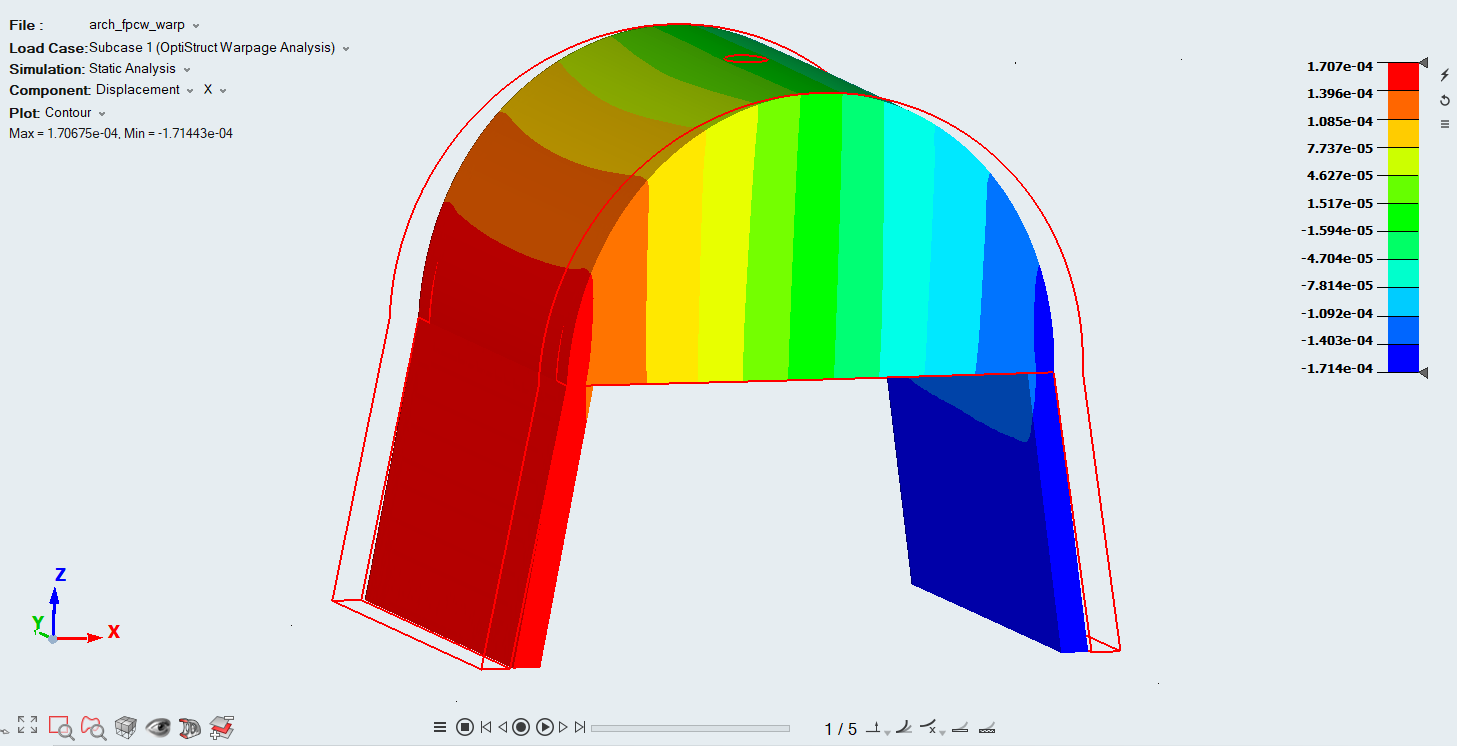

Warpage - Displacement

Due to non-uniform cooling, the molded part can warp. Warping can cause the part to fold, bend twist or bow. This contour help understands how the part is warping and make correcting measures in cooling rate, cooling channel design, or process data.

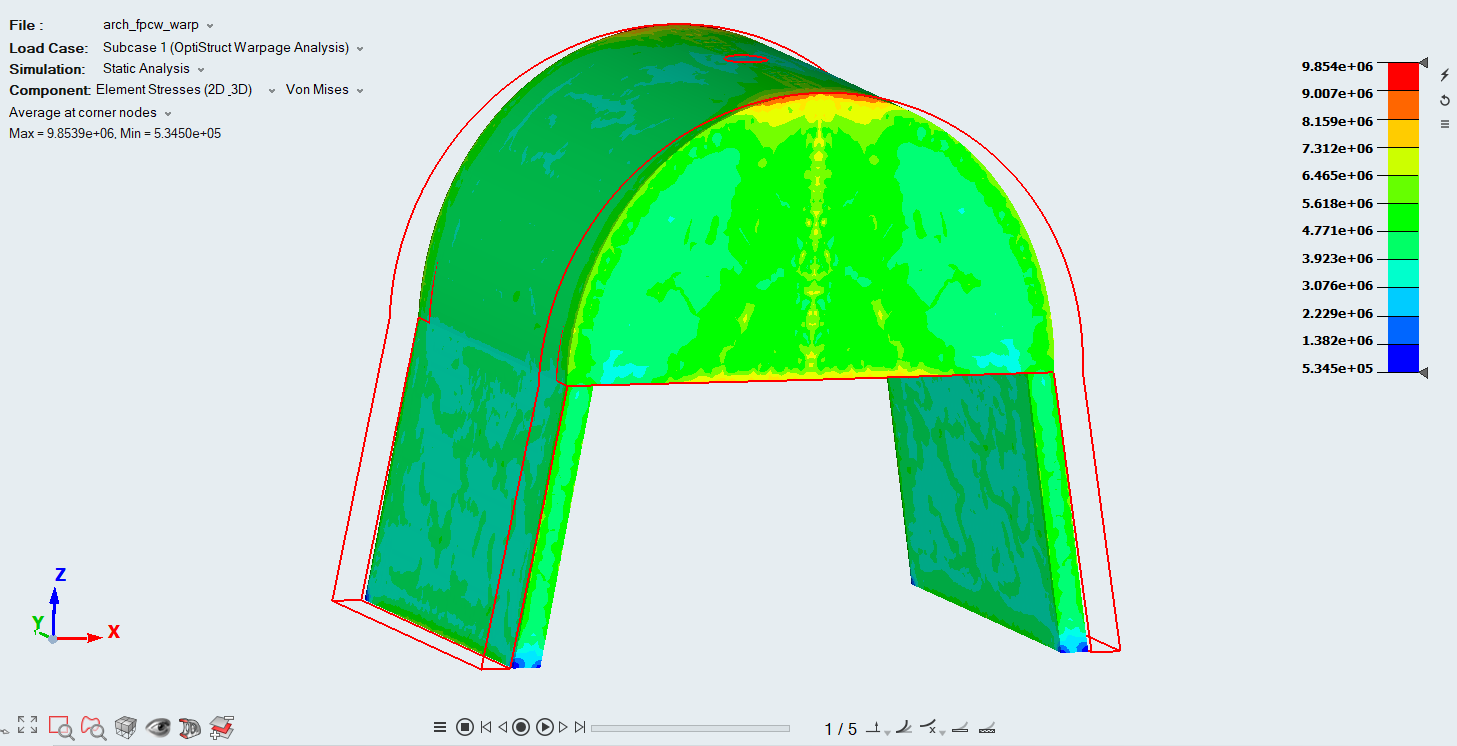

Warpage - Stresses

Due to non-uniform cooling, the molded part can warp and hence introduces stresses in

the molded parts. This data helps in determining regions with high-stress

concentration.