Material Database

This document provides information on available database in SimLab Molding and how to access/modify the material properties.

How to access the material database?

The material database can be viewed clicking on the Property tab in the Model Browser. Right click on Materials component and select Open Material database. This opens a window to select different databases. Make sure the Model browser is displayed. This can be done by selecting ‘Model Browser’ option under the View title bar or by clicking on F2 key.

System and user material database

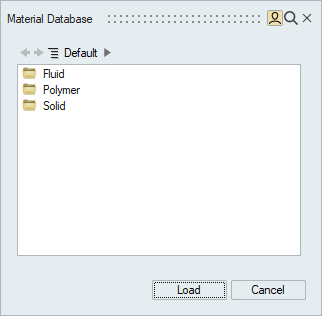

SimLab allows two types of databases namely User database and System database. System database contains default material properties for several materials. User database allows user defined material properties to be imported to the model. This feature can be accessed by clicking ‘Set User Material Database icon’ in the top right corner of the Material database window. By default, System database is selected as shown below.

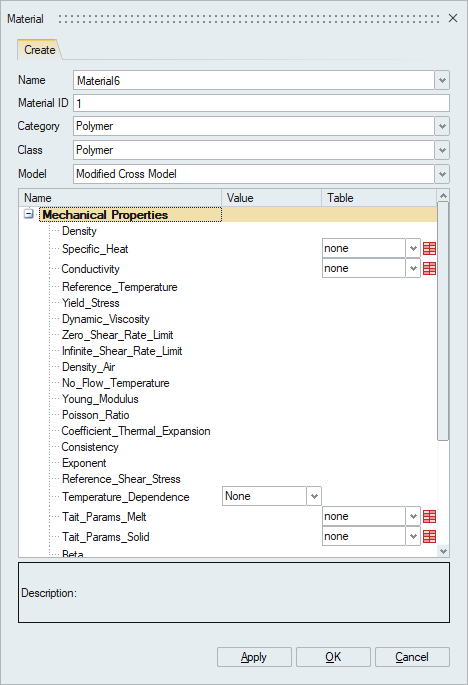

For polymers, the input values for specific heat, conductivity, melt tait parameter and solid tait parameter can be defined as tables. Click on the table icon next to these property fields and enter the table values manually. These inputs can also be imported from coma separated value file, generic data file or text file. Multiple file selection is not allowed. Click on the Select All button and delete all the cell values in the table in order to remove unwanted entries. The inputted tables can be edited in the under the Table component in the Model Browser. Figure 2 shows the default input mechanical properties for ABS_CYcolac_GPM5500 polymer. The input table values for specific heat are defined under FldTable1.

Five polymer models are available for molding process namely Modified Cross Model, Polymer Law Model, Carreau-Yasuda Model, Cross Model and Herschel-Bulkley Model. By default, the Modified Cross Model is selected. Users cannot edit the material data in the database. However, they can be loaded into the model and edited in the model browser.

How to create a solid material?

This sub-section explains how to create the thermal and mechanical properties of steel for molding analysis. Solid materials are used to define mold plates, mold inserts and part inserts. In the Property tab under the Model Browser, right click on the Materials component and select Create. Choose the Category as Solid, the Class as Metal and Model as Isotropic. Other options for material models are orthotropic, engineering constants and Johnson-Cook. Enter the following input values in the corresponding fields.

-

Thermal conductivity = 50

-

Heat capacity = 500

-

Density = 7800

How to create polymer material?

This sub-section explains how to create the thermal properties of polystyrene for molding analysis. Polymer materials are used to define sprue, runner, gate and melt inside the cavity. In the Property tab under the Model Browser, right click on the Materials component and select Create. Choose the Category as Polymer and the Model as Cross Model. Make sure that the Material ID is different from other defined materials.

-

Density = 995

-

Specific_Heat = 2300

-

Conductivity = 0.17

-

Reference_Temperature = 473.15

-

No_Flow_Temperature = 413.15

-

Coefficient_Thermal_Expansion = 3.4e-5

-

Reference_Shear_Stress = 24840

-

Temperature_Dependence = WLF

-

Beta = 0.005

-

WLF_ConstantC1 = 30.62

-

WLF_ConstantC2 = 51.6

-

WLF_Pressure_Dependency_D3 = 0

-

Glass_Transition_Temperature = 373.15

-

Activation_Energy = 75000