Convection

![]()

Description

This tool is used to specify the effective heat transfer between Polymer and Mold.

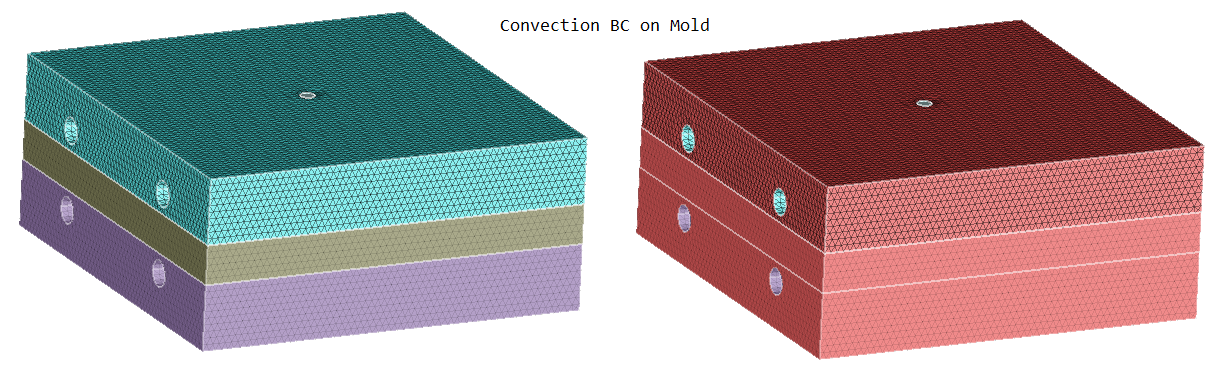

Convection Heat Transfer Conditions on External Surfaces

Poesis Mold Solver requires that every external face and every contact face between polymer and mold should have a BC specified on them.

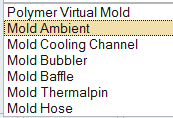

Heat transfer Coefficients can be of the following types. Use Polymer Virtual Mold for model without mold, others for model with mold.

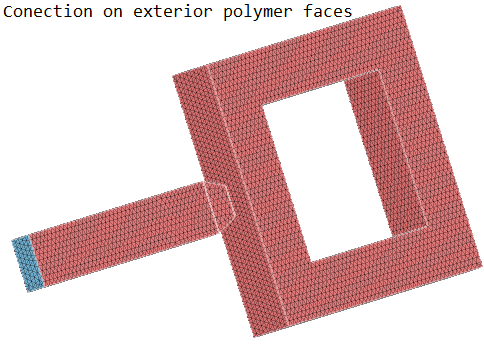

Polymer Virtual Mold

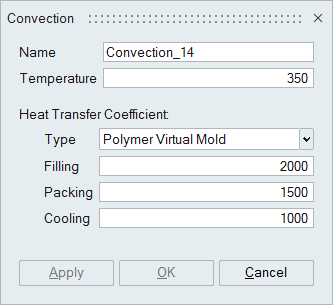

This condition is used on all external surfaces of polymer parts when mold is not included for analysis. This condition is used to specify the heat transfer between the polymer and the mold. Temperature specified is the average temperature of the mold. Heat transfer coefficient (HTC) specified is different for filling, packing, and cooling. To apply this BC:

- Select all the exterior faces on the polymer. Interior faces between gate/part shouldn't be selected.

- Specify name and temperature for the BC.

- In the Heat Transfer Coefficient, Select Type : Polymer Virtual Mold. Since heat

transfer differs based on molding stages, HTC also varies based on Filling,

Packing and Cooling.

Mold Ambient

This condition is used on all external surfaces of mold plates. This condition is used to specify the heat transfer between the mold and air surrounding it via natural convection heat transfer. HTC is approximately ~ 10 W/m^2-K and temperature is ~ 310 K.

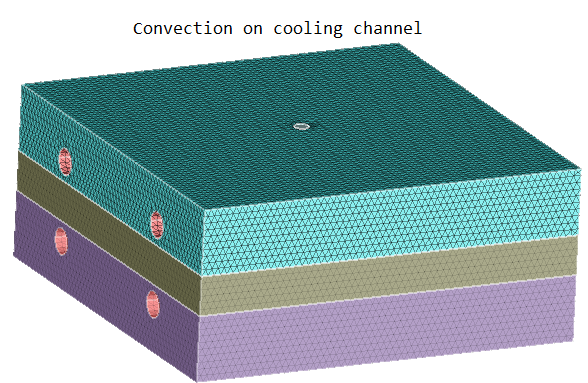

Mold Cooling Channel

This condition is used on coolant channel . This condition is used to specify the heat transfer between the mold and coolant via forced convection (turbulent) heat transfer. HTC is approximately ~ 10000 W/m^2-K and temperature of the coolant; is ~ 300

K.