Injection

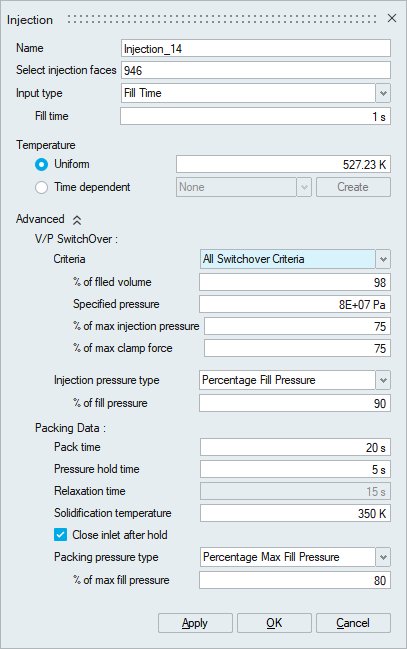

![]()

Description

In injection molding process, polymer melt is injected at the sprue inlet.

Most users will know the fill time, melt velocity (flow rate) and the temperature at the inlet. These form the inlet conditions.

In a typical process, part is filled in one or two seconds. Hence, from the volume of the cavity and inlet injection area, we can compute the flow rate or velocity.

flow rate = (volume to be filled)/(fill time)inlet velocity = (flow rate)/(injection area at the inlet)

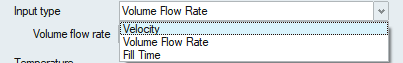

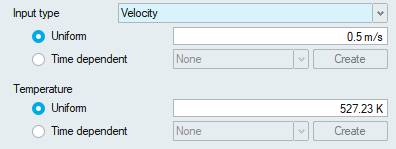

Inlet flow condition can be defined using (normal) velocity or volume flow rate or Fill Time. Velocity is always specified in the normal direction to the surface on which it is injected. Hence, it is also denoted as normal velocity.

Varying Velocity and Temperature can be applied as function of time.

Advanced options

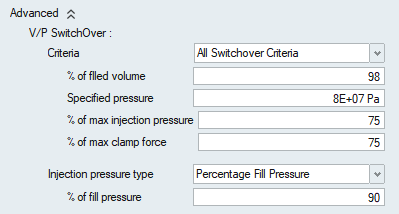

V/P Switchover criteria can be defined using All SwitchOver Criteria, Percentage filled volume, Specified Pressure, Percentage Max Injection Pressure and Percentage Max Clamp Force or None.

Injection Pressure Type can be defined using Pressure Value, Percentage Fill Pressure or Percentage Max Machine Pressure.

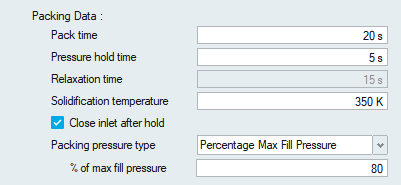

If Pack Analysis stage is selected, Packing Data can be defined in advanced options.

Model without Mold

Steps

- Specify name of Injection BC.

- Specify value for velocity or volume flow rate or fill time depending on options picked for Input type

- Specify value for velocity or volume flow rate depending on options picked for Inflow type

- Specify temperature of polymer at injection point

- Select injection face from mesh body

- Click on OK button to accept the changes. you can see injection face with proper

legend.

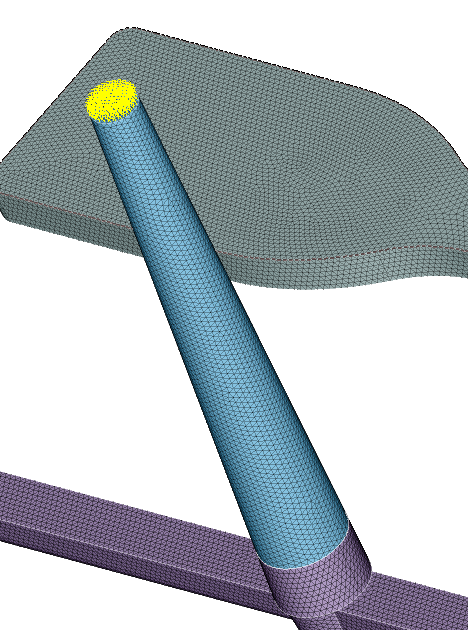

Models with Mold

- These models should be meshed such that, the sprue inlet comes to the mold external wall and it is exposed. That is, it cannot be inside the mold and enclosed by it.

- Inlet is always specified on the polymer part (sprue).

- Steps to create injection BC is same explained in previous section.