Liquid Cooling

![]()

Introduction

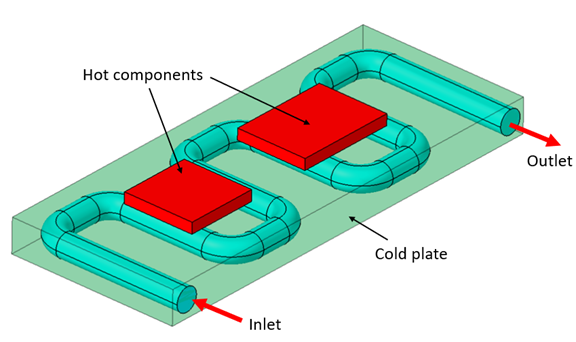

Liquid cooling is an ElectroFlo smart object used for defining the cooling liquid region with specific flow parameters.

Description

- Electronic components can have advanced cooling entities, such as liquid cooling, to avoid thermal damage.

- Liquid cooling smart object is used to define all the required liquid

cooling parameters combinedly in a single GUI.

- User can define the liquid cooling region by selecting the bodies applied with “Fluid” materials.

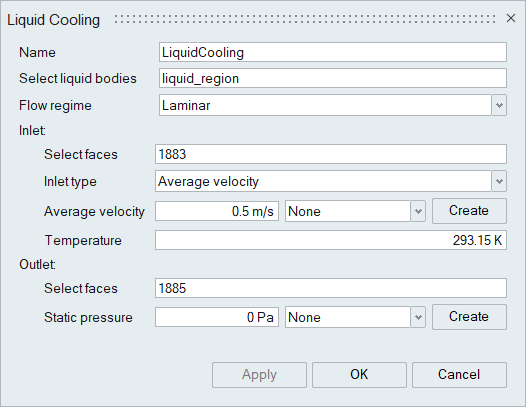

- The Flow regime for the cooling liquid region can be set as,

- Laminar

- Turbulent

- Turbulent flow regime can be solved by the below methods.

- Standard K-epsilon

- Zero equation

- Spalart–Allmaras

- User can select the inlet face regions and define the Inlet parameters

as,

- Mass flow rate

- Volume flow rate

- Average flow velocity.

- Temperature must be also defined in the inlet region.

- Outlet pressure can be defined by selecting the outlet face region and entering the corresponding value in the “Static pressure” field.

- Inlet Flow parameters and outlet pressure can be either constant or variable

if a multiplier function is defined.

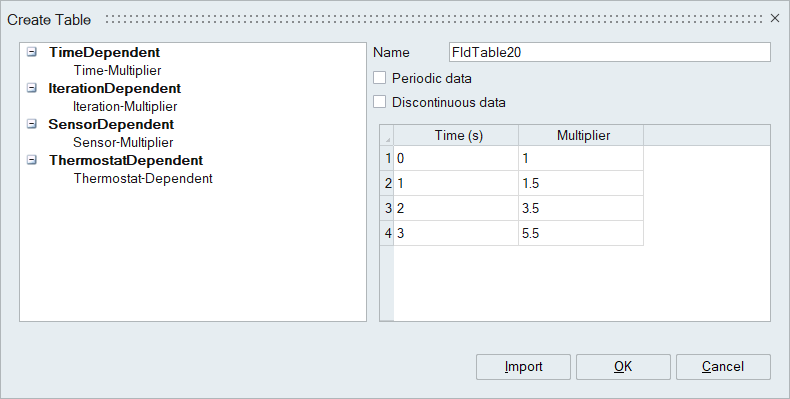

- There are three types of multiplier tables:

- Time - Multiplier value varies as a function of time in transient simulations.

- Iteration - Multiplier value varies as a function of the iteration number in steady-state simulations.

- Sensor – Multiplier value varies based on the selected sensor output.

- Thermostat - Multiplier value varies based on the ON/OFF status of the selected thermostat.

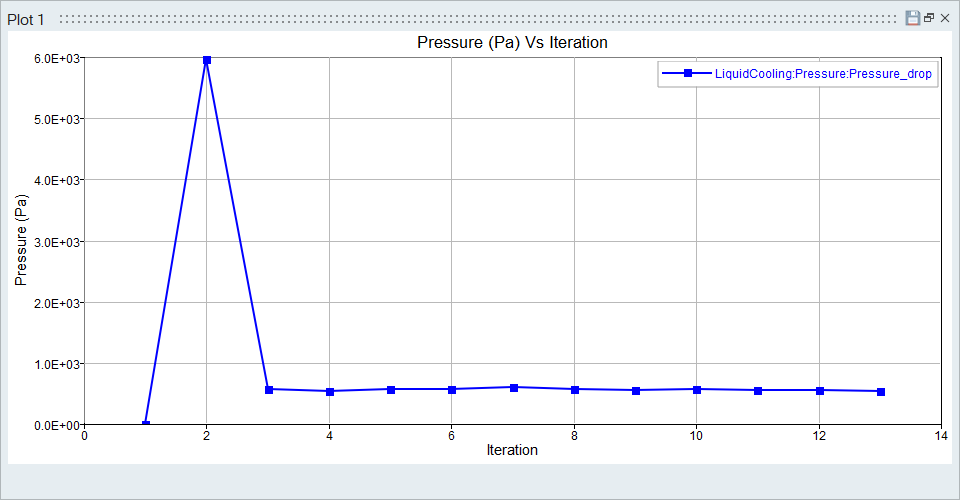

Graph Plotting

Pressure drop and Heat transfer parameters can be plotted by right click on “Liquid cooling” under “Smart Objects” in the solution browser.