Manufacturing Check

Manufacturing check configurations.

Graphical User Interface Default Settings

- slide-number

- The initial slide number that is displayed on the report.

- action

- Action items.

- input

- Initial director for CAD input.

- output

- Initial director for results output.

Hole Details

- min-diameter

- The minimum diameter for the surface hole recognition. Holes below this diameter will be ignored.

- max-diameter

- The maximum diameter for the surface hole recognition. Holes above this diameter will be ignored.

- min-nodes

- The minimum number of nodes to recognize the finite element (FE) hole. Holes with nodes less than this number will be ignored.

- max-nodes

- The maximum number of nodes to recognize the finite element (FE) hole. Holes with nodes greater than this number will be ignored.

- adjacent-tolerance

- Distance to judge the duplicate holes for the same plate. If the Holes-to-Holes distance is less than this value, it is considered as a duplicate hole.

Connector Database

- Spot connection

- Spot CAD Entity: Points/solids/lines/cdh-data.

- Arc/Seam connection

- Arc CAD Entity: Surfaces/lines.

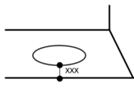

Checks

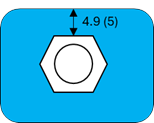

- Nut bolt seating surface check.

Detects the holes in the model which do not have connectors around them.

Figure 1.

- Do check

- Check on/off.

- Feature angle

- Internal mesh face-to-face angle.

- Feature distance tolerance

- Distance between the nut's outer edge to the nearest surface's free edge.

- Tolerance for judgement

- Allowable tolerance for "OK" or "Not good".

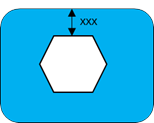

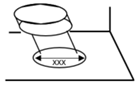

- Stud seating surface check.

Detects the bolts and nuts which do not have corresponding holes to fit in.

Figure 2.

- Do check

- Check on/off.

- Feature angle

- Internal mesh face-to-face angle.

- Feature distance tolerance

- Distance between the nut's outer edge to the nearest surface's free edge.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

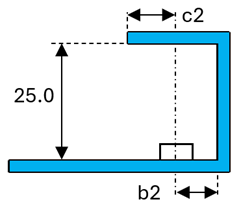

- Electrode interference check.

Detects the bolts which have a hole around it, but the distance between the bolt center and hole center is more than the threshold value.

Figure 3.

- Do check

- Check on/off.

- a2

- Distance between the bottom of the nut to the plate.

- b2

- Distance between the center of the nut to the plate.

- c2

- Distance between the center of the nut to the plate's edge.

- Free edge distance tolerance

- Value appended to a2, b2, and c2.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

- Spot weld surface area check.

Detects the nuts which have a hole around it, but the distance between the nut center and the hole center is over the threshold.

Figure 4.

- Do check

- Check on/off.

- Thickness threshold

- CSV table thickness value.

- Radius if thickness is below threshold

- Radius of the imaginary circle.

- Radius if thickness is above threshold

- Radius of the imaginary circle.

- Free edge distance tolerance

- Distance between the imaginary hole and the free edge.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

- Spot weld pitch check.

Based on the plate material, it checks the distance between weld locations. The required distance is calculated based on the CSV file table.

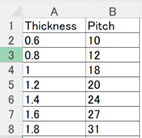

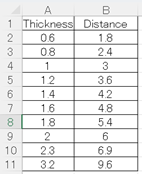

Figure 5.

- Do check

- Check on/off.

- Pitch threshold CSV file

- File selection: Spot_pitch.csv.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

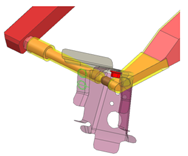

- Spot gun interference check.

Collision check between the spot gun and the weldable assembly model.

Figure 7.

- Do check

- Check on/off.

- Spot gun file

- Spot gun CAD data: Catia, NX, JT, IGES, and so on.

- Angle increment

- Incremental rotation angle at once (15, 30, or 45, for example).

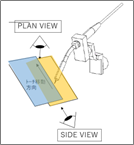

- Arc weld torch interference check.

Collision check between the arc torch, the weldable nut, and the assembly model.

Figure 9.

- Do check

- Check on/off.

- Torch file

- Spot gun CAD data: Catia, NX, JT, IGES, and so on.

- Min tilt angle

- Start angle (15, 30, or 45, for example).

- Max tilt angle

- End angle (15, 30, or 45, for example).

- Tilt angle increment

- Incremental rotation angle at once (5, 10, or 15, for example).

- Rotation increment

- Incremental rotation angle at once (15, 30, or 45, for example).

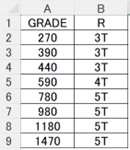

- Fillet radius check.

Checks the fillet radius against the material grade.

Figure 11.

- Do check

- Check on/off.

- Minimum fillet radius

- Minimum fillet radius.

- Maximum fillet radius

- Maximum fillet radius.

- r threshold CSV file

- Select the file that has a fillet radius table.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

- Trim line radius check.

Checks edge fillet radius values against user-set value.

Figure 13.

- Do check

- Check on/off.

- Pitch between points

- Default: 1.0.

- R threshold

- User-defined fillet value.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

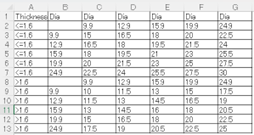

- Hole pitch check.

Checks the distance between the nearest holes against the threshold value from the CSV file.

Figure 14.

- Do check

- Check on/off.

- Pitch threshold CSV file

- Select file that has the fillet radius table.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

- Hole size check.

Checks the distance between the nearest holes against the threshold value set in the CSV table.

Figure 16.

- Do check

- Check on/off.

- Diameter threshold CSV file

- Select the file that has the fillet radius table.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

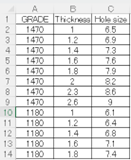

- Hole size of nut bolt check.

Checks the distance between the nearest holes. If it less than the threshold, then reports are generated.

Figure 18.

- Do check

- Check on/off.

- Nut diameter difference

- Allowable tolerance for the nut's diameter.

- Bolt diameter difference

- Allowable tolerance for the bolt's diameter.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

- Corner radius of oblong designed hole check.

Checks the radius of the oblong holes at the corners against the threshold value in the configuration file.

Figure 19.

- Do check

- Check on/off.

- Pitch between points

- Default: 1.0.

- R threshold

- User-defined radius.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

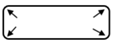

- Distance trim line hole end check.

Checks the distance between the hole edge against the nearest surface edge, and compares the result with the CSV table.

Figure 20.

- Do check

- Check on/off.

- Distance threshold CSV file

- File selection: Distance_trimline_hole_end.csv.

- Tolerance for judgement

- Allowable tolerance for pass/fail.

- Part interference check.

Checks the gap between the nearest parts at the physical location without surface offset. You can perform a surface offset to check at the mid location.

Figure 22.

- Do check

- Check on/off.

- Clearance

- Allowable tolerance for pass/fail.