Skeleton Modeling

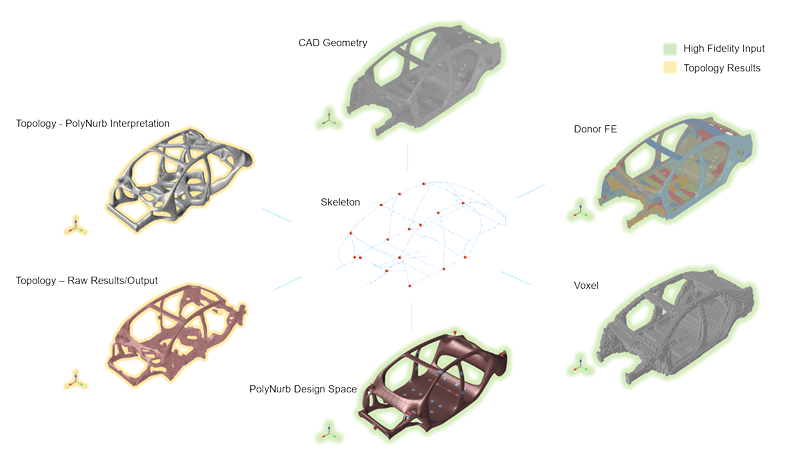

Create a reduced ordered model to facilitate optimization at the concept phase.

Skeleton modeling is independent of industry and can be used for a variety of modeling needs. It can be used purely for model build purposes and/or for concept optimization.

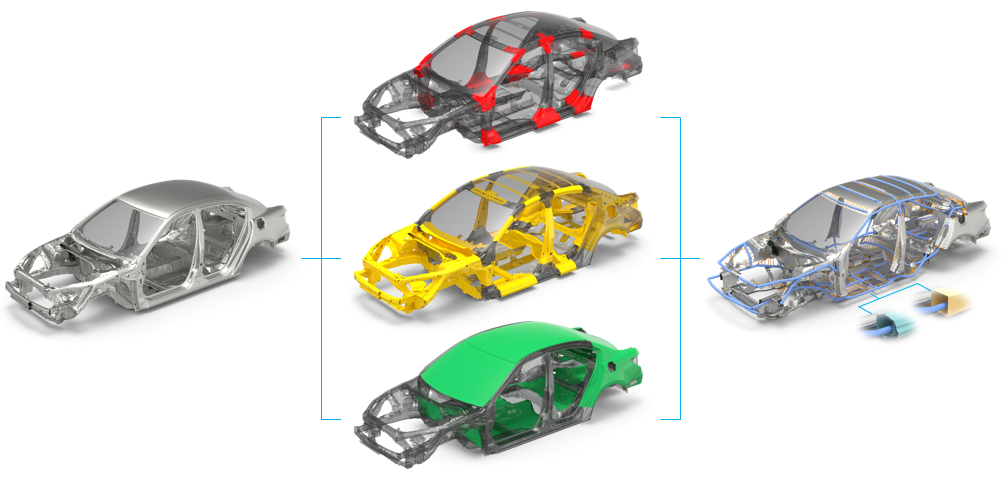

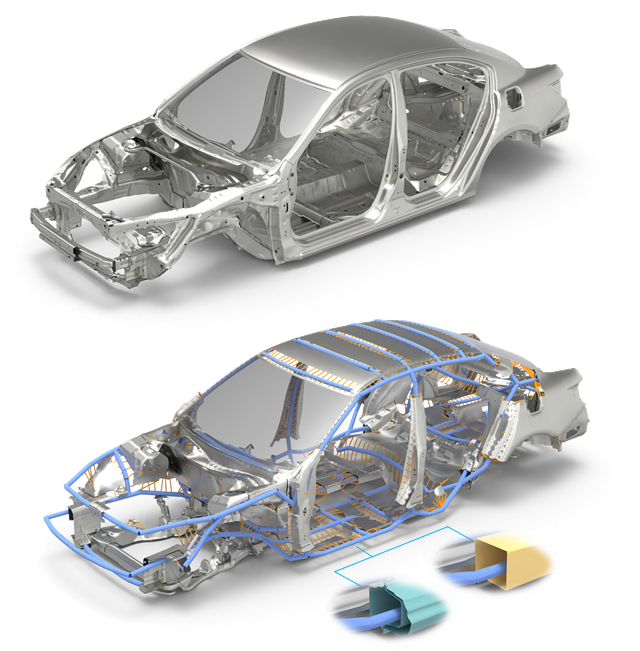

Once the skeleton model is built, it’s necessary to verify and certify that the low fidelity model correlates with the original high-fidelity model (assuming the source is donor FE).

Once the correlation is complete, optimization studies can be performed to meet certain performance metrics.

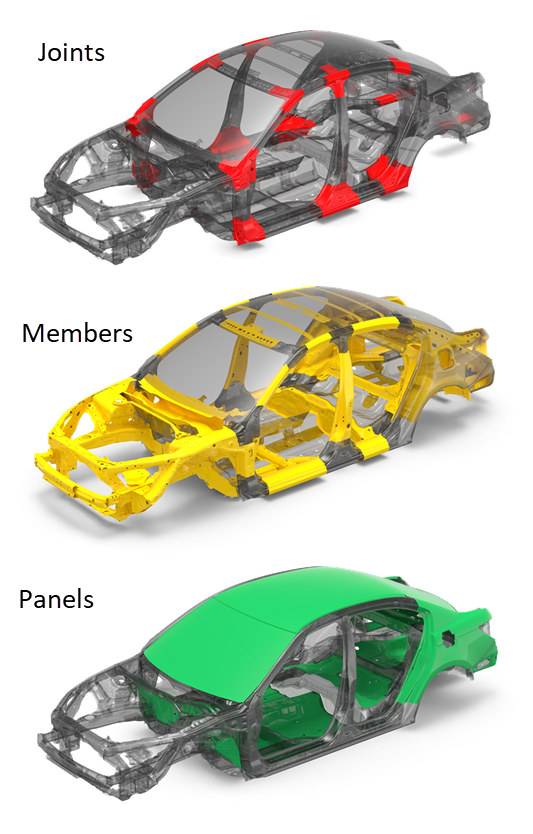

The skeleton model build process is dissected into three key stages – Joints, Members, and Panels.

The model build creation process starts by isolating the areas to be considered as a joint. These are typically junctions in the model that have multiple joining locations within the physical structure.

Each member is connected between two joints.