Thermal Pad

Check rule for component thermal pads.

- Checking

- Item: Specify the item name.

- Component Group: Select target components from component group list.

- Exclude Component Group: Select void-checking components among target components by selecting void-checking component group list.

- Checking Option: Upon double-clicking column, the new

optional dialog will appear. In the dialog, set

detail checking options.

- Thermal Pad Definition: Define the criteria to recognize the

Thermal Pad in the component area.

- Pad: Recognize as a Thermal Pad if the Pad is placed inside the component area.

- Copper Polygon: Recognize as a Thermal Pad if the Copper-Pour is filled inside the component area.

- Laser Via Definition: Define the Laser Via.

- Minimum Hole Size: Define the Laser Via with the Hole Size. Vias with the hole size below the entered value are considered as the Laser Via.

- Via PadStack Selection: Select the Laser Via through the Via PadStack list directly.

- Check the Number of Solder Mask and Metal Mask in Thermal

Pad: Check the number of solder / metal masks.

- Size / Area: Selecting searching unit between size and area.

- Item: Specify the item name.

- Pad Size/Pad Area: Depending on target pad searching unit, set the value range of size or area.

- Number of Solder Masks: Set the number of solder masks. If the number of solder masks does not match the given value, it is a fail.

- Number of Metal Masks: Set the number of metal masks. If the number of metal masks does not match the given value, it is a fail.

- Checking Options

- Target Via: Select the target via.

- Through Via: Option to include the Through hole via from checking.

- Blind Via: Option to include the Blind via from checking.

- Buried Via: Option to include the Buried via from checking.

- Laser Via: Option to include the Laser via from checking.

- Via Measure Base: Select measure base for via.

- Hole Shape: Measure based on the edge of the Via Hole Shape.

- Via Pad: Measure based on the edge of the Via Pad shape.

- Via Location: Measure based on the center of the Via Pad shape.

- Check Existence of Thermal Pads in Target Component: Check if target component has thermal pad or not. If it has no thermal pad, PollEx DFM detects it.

- Check Existence of Vias in Metal Mask Region: Check if vias are placed on metal mask in thermal pad. If vias are placed on metal mask region, it is a fail.

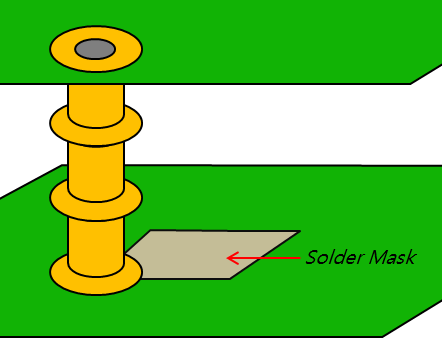

- Check Existence of Solder Mask in Via’s region at

reverse Side of Thermal Pad: Check if solder mask is

overlapped with via on reverse side of thermal pad

placed layer. If so, it is a fail.

Figure 1. - Check co-Existence of Solder Mask and Metal Mask in Thermal Pad: Check if solder mask and metal mask exist at the same time. If one of them is not in thermal pad, it is a fail.

- Check Size Matching with Solder Mask and Metal Mask in Thermal Pad: Check metal mask and solder mask size. If they are not same in size, it is fail.

- Expand Thermal Pad Area: Set the expanding size value for thermal pad region.

- Check direct Connection between Pin and Thermal Pad: Check if there is a routing pattern connecting thermal pad and pin of component. If there is direct connection, it is a failed.

- Clearance between Via and Via in Thermal Pad: Check clearance between via and via in Thermal Pad area.

- Clearance between Thermal Via and the Component Pads placed on the opposite side of the Thermal Pad.

- Check the Number of Vias in Thermal Pad: Check the

number of vias in thermal pad.

- Number of \Vias: Specify the number of vias. If the result does not match the given number, it is a fail.

- Exclude GND connected Via: If this option is checked, exclude GND connecting vias in counting the number of vias.

- Exclude Vias overlapped with Silkscreen: If this option is checked, exclude silkscreen overlapped vias in counting the number of vias.

- Clearance between Thermal Pad and Via: Check

clearance between thermal pad and vias.

- Clearance: Set the clearance value between thermal pad and vias.

- Exclude GND connected Via: If this option is checked, exclude GND connecting vias in counting the number of vias.

- Do not check in case of Thermal Pad and Via have same Net: If via and thermal pad have same net name, PollEx DFM will not do clearance checking.

- Target Via: Select the target via.

- Thermal Pad Definition: Define the criteria to recognize the

Thermal Pad in the component area.