Solder Resist Pad

Solder Resistor (SR) is a material which is applied to specific areas of the printed circuit board during a soldering process and protects the circuit of the unnecessary portions of solder.

- Solder Mask Layer Definition

- Top: Define the Solder Mask layer of the Top layer.

- Bottom: Define the Solder Mask layer of the Bottom layer.

- Checking

- Item Name: Specify the item name.

- Component Group: Select target components with component group selection.

- Check Options: Upon double-clicking column, Check Options,

run checking option dialog as below.

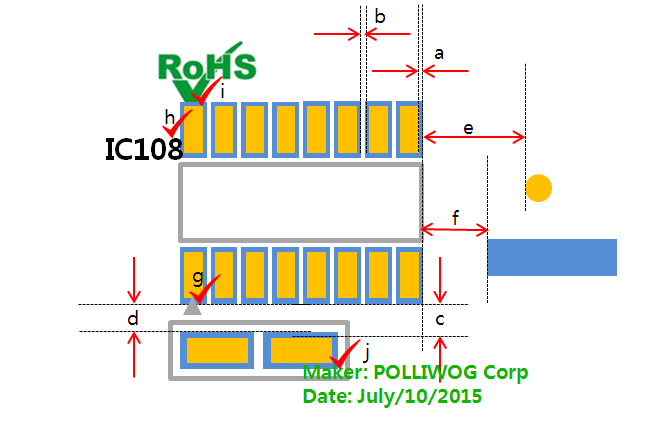

Figure 1.- Clearance between Solder Mask and Pad in Same Component: Set

the clearance value between solder mask and pad.

-

- SMD: Set the clearance value between solder mask and SMD pad.

- NSMD: Set the clearance value between solder mask and NSMD pad.

- Maximum distance between Solder Mask and Pad in same

Component: Even if the distance between the pad and

solder mask satisfies the upper inspection option

Clearance condition, if it exceeds the maximum

distance value Fail

- SMD: Set the clearance value between solder mask and SMD pad.

- NSMD: Set the clearance value between solder mask and NSMD pad.

- Regard Pad as Pass with having greater than given value for any direction: On the clearance checking between the edges of Pad and Solder Mask, this option is considered to pass if either direction is satisfied.

-

- Clearance between Solder Masks in Same Component: Set the clearance value between solder mask and solder mask.

- Clearance between Pad and Other Component’s Solder Mask: Set the clearance value between pad and other components’ solder masks.

- Clearance between Solder Mask and Other Component’s Solder Mask: Set the clearance value between solder mask and other component solder masks.

- Clearance between Solder Mask and Board Figure Pads: Set the clearance value for solder mask and board figure type pads.

- Clearance between Solder Mask and Board Figure Solder Masks: Clearance checking between the Solder Masks of Pad and Board Figure.

- Clearance between Solder Mask and other Net: Clearance

checking between the Solder Masks of Pad and Net.

- Recognize as different nets if other nets are connected to the same reference.

- Check exposed copper on the same net due to solder mask.

- Solder Mask Overlapping with Component Figure Silkscreen: Option to check the area where the Solder Mask and Component Figure silkscreen overlap. Overlapped area is considered as fail.

- Solder Mask Overlapping with Component Text Silkscreen: Option to check the area where the Solder Mask and Component Text silkscreen overlap. Overlapped area is considered as fail.

- Solder Mask Overlapping with Board Figure Silkscreen: Option to check the area where the Solder Mask and Board Figure silkscreen overlap. Overlapped area is considered as fail.

- Solder Mask Overlapping with Board Figure Text Silkscreen: Option to check the area where the Solder Mask and Board Figure Text silkscreen overlap. Overlapped area is considered as fail.

- Check Existence of Solder Mask in Target Component’s Pin: Check whether target component’s pin has solder mask or not.

- Check the existence of Solder Mask between Thermal Pad and I/O Pad: Check whether Solder Mask exists between Thermal Pad and I/O Pad.

- Solder Mask Usage

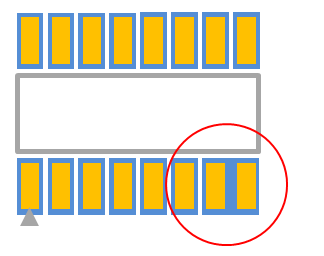

- Check Solder Mask usage in multiple Pins: Check multiple

shares same solder mask.

Figure 2. - Check Solder Mask usage between Pins(Only 2Pin Component): Option to check whether the Solder Mask is filled between the Pads where the component has only 2 pins.

- Check Solder Mask Covered on Component Area: Option to check whether the component area is covered with the Solder Mask.

- Measure Base: Select measure base.

- Expand Component Boundary: Enter the value to be expanded the component boundary area.

- Clearance between Solder Mask and Pad in Same Component: Set

the clearance value between solder mask and pad.

- Remainder: Check above same rules for components which are not listed in table.

- Display Fail Results for Each Pin: Display the fail results for each pin of the component.

- Board Figure Solder Mask: Checking rules for solder masks belong to

board figure.

- Clearance between Board Figure Solder Mask: Set the

clearance value between board figure solder masks and others.

- Including Board Figure having Pad: Option to include the Solder Mask of Board Figure having Pad.

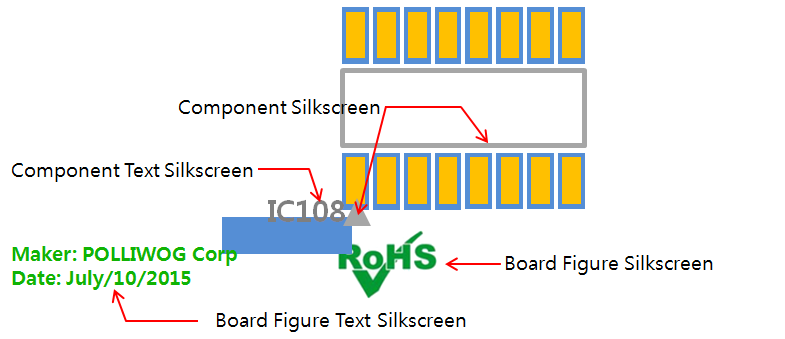

- Overlapping with below Types of Silkscreen: Check silkscreen

data’s overlapping with board figure geometries.

Figure 3.- Component Figure: Option to check whether the Solder Mask and Component Figure silkscreen overlap.

- Component Text: Option to check whether the Solder Mask and Component Text overlap.

- Board Figure: Option to check whether the Solder Mask and Board Figure silkscreen. overlap.

- Board Figure Text: Option to check whether the Solder Mask and Board Figure Text silkscreen overlap.

- Clearance between Board Figure Solder Mask: Set the

clearance value between board figure solder masks and others.