BGA

Check the rules for BGA component clearance and via placements near pins.

- BGA Component Definition

- BGA Component Group: Select the BGA component group from the predefined component group list.

- Laser Via Definition: If laser vias are used on PCB design, it is able to

check the clearance with certain value.

- Maximum Hole Size: Can define the via with having hole size.

- Via Padstack Selection: Can define the via with using name.

- Padstack String: Can define the via with using string filter.

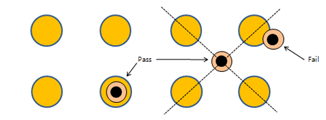

- Via Location Checking: Check the via location. Depending on the options, if

the via is placed among the center of the pins or at the same location, it

passes.

Figure 1.- Pass for the center of 4BGA Pins.

- Tolerance: Even if a Via Location design violation occurs, if it is within the inputted tolerance value, it is regarded as a pass.

- Pass for the same BGA Pin’s Location.

- Tolerance: Even if a Via Location design violation occurs, if it is within the inputted tolerance value, it is regarded as a pass.

- Pass for the center of 4BGA Pins.

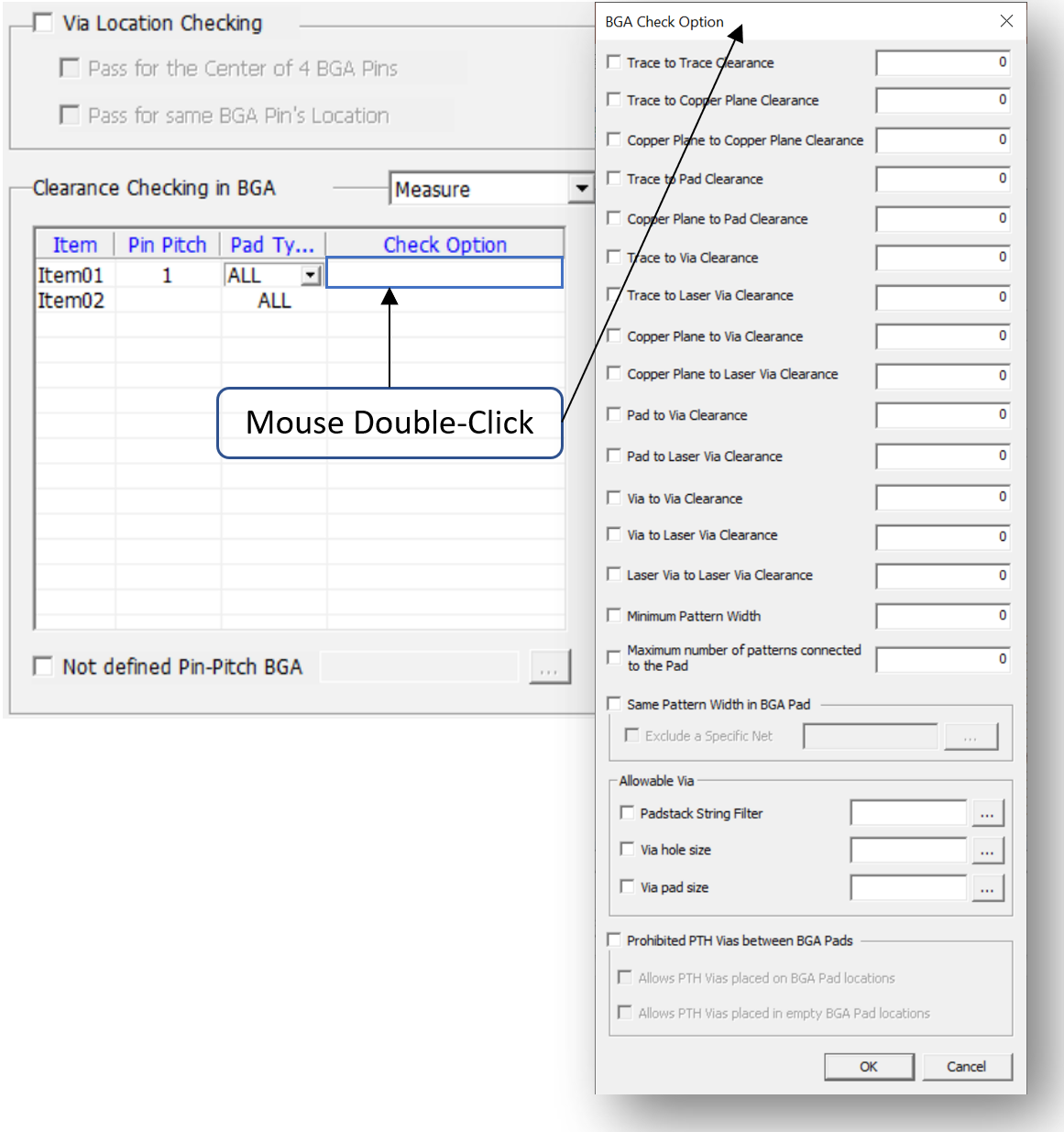

- Clearance Checking in BGA: Among defined BGA components, pick the BGA

components with certain pin pitches and specify special clearances for

different items. Set the pin pitch and double-click the Check

Option column. In the dialog, set various clearance options

and click OK to save them.

In the column, selected clearances option numbers will be displayed.

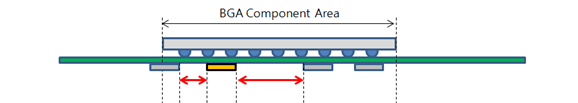

Figure 2. - Clearance between Components under BGA Area on BGA’s Reverse Side: For

components that are placed on the reverse side of BGA components and under

the BGA component area, use PollEx DFM to check the

clearance among them. Select the component group1, component group2, and set

the clearance values to complete rule.

Figure 3.