Stiffener

Check rules of stiffener.

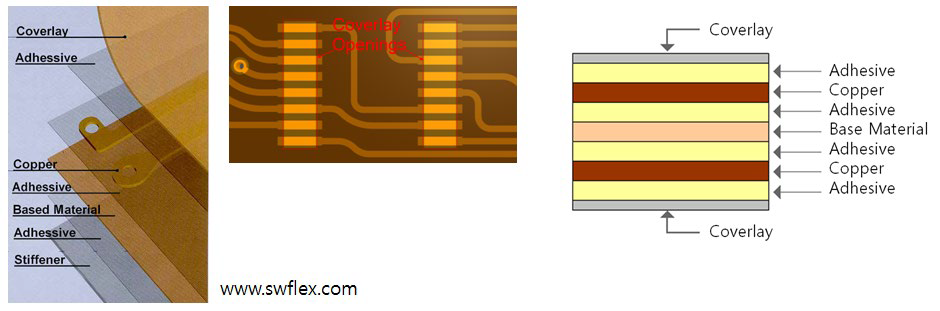

Figure 1.

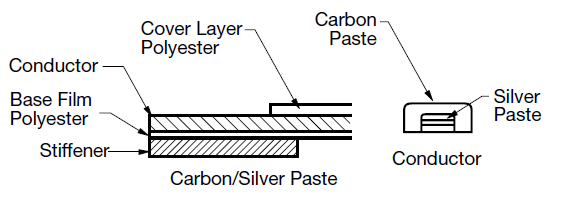

Figure 2.

- Stiffener Layer Definition: Define stiffener layer for the top and bottom.

- Stiffener Top Layer: Select stiffener top layer from the layer list.

- Stiffener Bottom Layer: Select stiffener bottom layer from the layer list.

- Target Component Definition: Define target components.

- Component Selection: Select target components from the component group list.

- Exclude Components from Board’s Outline within given Distance: Exclude components, placed near board outline. To select void –checking component, set the distance between the component and board outline.

- Checking

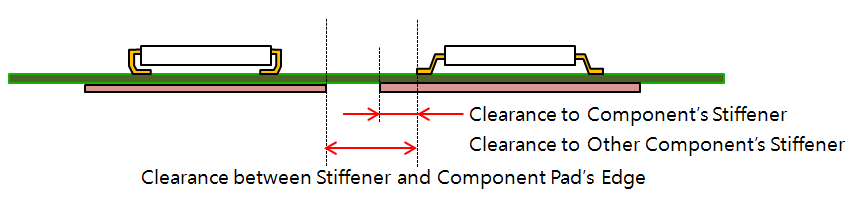

- Clearance between Component Stiffener and Component’s Pad: Check the

clearance between the component stiffener and the component

pads.

Figure 3.- Additional Void-Checking Component Selection: Add a new additional void-checking component group by selecting a component group from the list.

- Clearance between Other Component Stiffener and Component’s Pad: Check the clearance between the other component stiffener and component pads.

- Stiffener Existence at reverse Side of Target Component: Certain components must have stiffener on the other side. Check the existence of stiffener on the reverse side of target components.

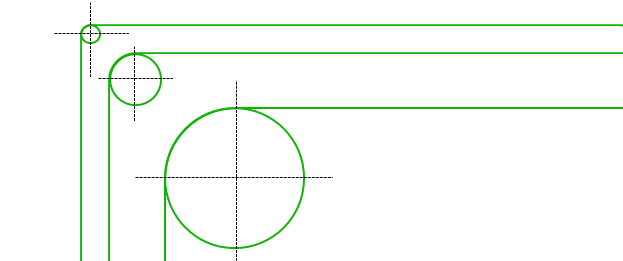

- Check Stiffener’s Rounding in Corners: Check whether stiffener

corners are rounding. To check the sharp angle, use the radius in

the corner.

Figure 4.- Minimum Radius for Stiffener’s Angle: Set the minimum radius values.

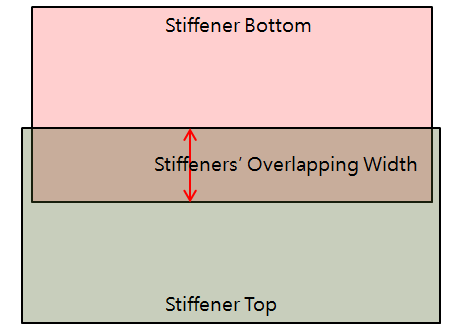

- Minimum Overlapping Width between Top and Bottom Stiffener: If there

are top and bottom stiffeners in the same area, check the

overlapping width.

Figure 5. - Checking for stiffener overlapping with component on same side:

Option to check whether the component is designed to overlap with

the Stiffener placement area.

- Except component Group: Select a component group to exclude from checking.

- Clearance between stiffener edge and via: Clearance checking between stiffener and via.

- Check Uniform Pattern in both Side from Stiffener’s Edge: The

stiffener boundary is likely to be folded or bent due to the nature

of the FPCB. The possibility of breaking the routing increases if

the width of the routing becomes narrow or the angle of routing is

changed. This option extends the checking area from the outside of

the stiffener by the entered value.

- Width: Check whether the width of the routing is changed in the checking area.

- Angle: Check whether the routing is bent in the checking area.

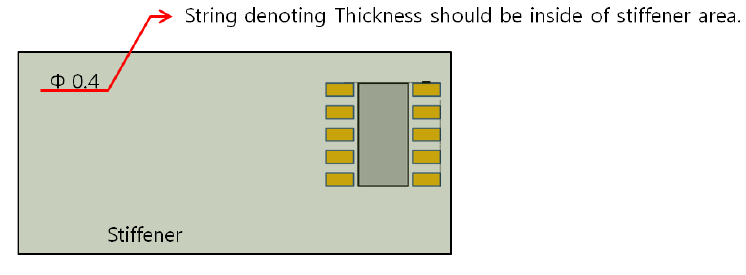

- Check Existence of String for Stiffener’s Thickness: Check if there

is text string, denoting the thickness of a stiffener in the

stiffener area. The string should be matched with given thickness

value.

Figure 6.- Define Top Placed Stiffener’s Thickness: Set the top stiffener thickness value.

- Define Bottom Placed Stiffener’s Thickness: Set the bottom stiffener thickness value.

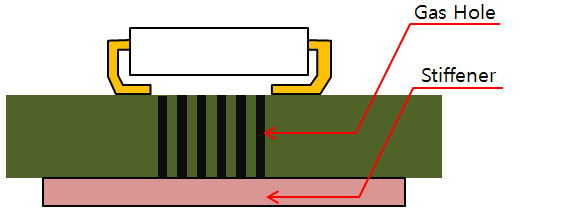

- Gas Hole Stiffener: If there are gas-holes under components, you can

make rules for gas holes.

Figure 7.- Gas Hole Layer Selection: Define the gas-hole layer by selecting a layer from the layer list.

- Minimum Gas Hole Size: Set minimum gas hole size.

- Check Existence of Gas Hole in Stiffener: Check if there are gas holes in stiffener area.

- Clearance between Gas Hole and Stiffener: Set the clearance value between gas hole and stiffener.

- Clearance between Component Stiffener and Component’s Pad: Check the

clearance between the component stiffener and the component

pads.