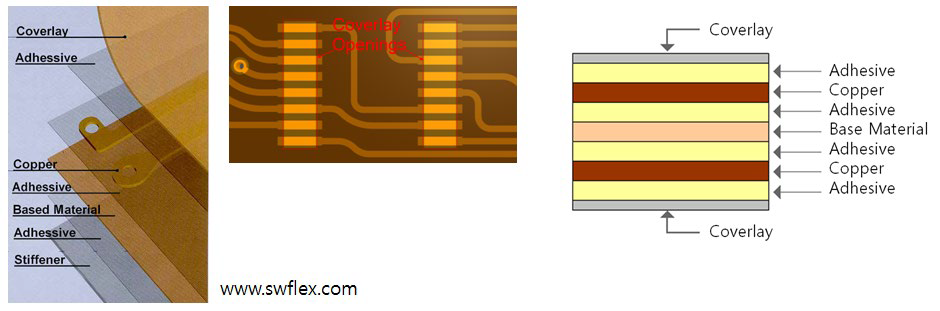

Coverlay Open Area

Check rules for Coverlay.

Figure 1.

- Target Layer Definition: Define target layer for checking.

- Layer Definition for Check Area: Select target layer from layer list.

- Coverlay Layer Definition: Define Coverlay layer for checking.

- Coverlay Data Type: Select Coverlay layer data type between Positive and Negative.

- Top/Bottom: Select Coverlay top and bottom layer from layer list.

- FPCB Layer Definition: If PCB is a mixed design, as in FPCB (Flexible PCB)

and Rigid PCB together, it is able to check the clearance with a certain

value for FPCB. In this case, you can define the FPCB layer for checking.

- Layer Name or Layer Comment: Can define the FPCB layer information by layer name or comment of layer.

- FPCB Layer Filter: Set the layer information.

- Checking: Check Coverlay opened for patterns and vias.

Figure 2.- For coverlay opening, check Pattern existence: Check pattern

Coverlay opening.

- Exclude Checking for Coverlay Opened for Both Sides: If pattern Coverlay data are open in the top and bottom, PollEx DFM will not check for this pattern.

- For coverlay opening, check Via existence: Check via Coverlay opening.

- Exclude Checking for Nets: Exclude vias connected to certain nets. To do this, select nets from netlist.

- In Case of Via on Pad, Check Coverlay on the Other Side of Component

Placement: If a via is placed on pad, check the other side to see if

there is a Coverlay or not. If there is no Coverlay on the other

side, it is a fail.

Figure 3.- Except for Selected Via Hole Size: For certain size of via holes, exclude checking for them.

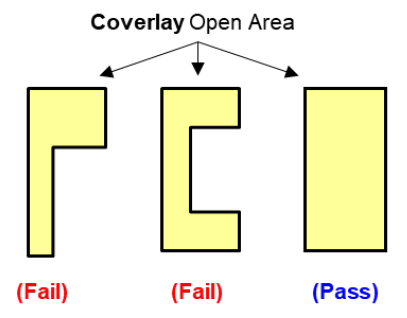

- Checking if the coverlay open area is rectangle shape: Check whether

the coverlay open area is designed in a square shape in order to

prevent the coverlay film from tearing.

Figure 4.

- For coverlay opening, check Pattern existence: Check pattern

Coverlay opening.