Solid

Realization Details

- Solid Type

-

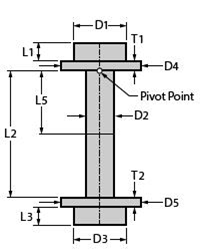

Figure 1. Pattern 1: Tapered Bolt

Figure 2. Pattern 2: Tapered Bolt with Washer

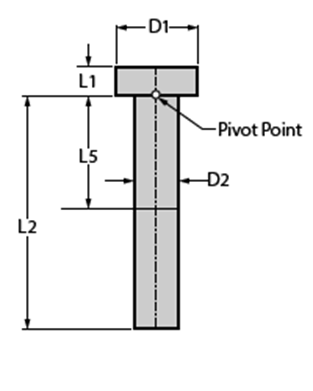

Figure 3. Pattern 3: Straight Bolt

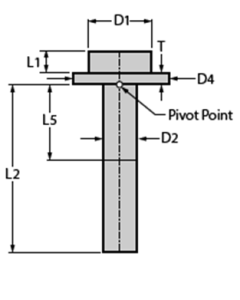

Figure 4. Pattern 4: Straight Bolt with Washer

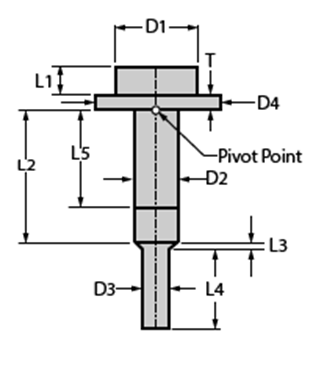

Figure 5. Pattern 5: Double Sided Bolt

Figure 6. Pattern 6: Double Sided Bolt with Washers

- D1

- Diameter of the bolt head.

- D2

-

- Input

- A manually defined diameter of the bolt shaft.

- Auto

- The connector will automatically take the diameter of the smallest hole and set it as the diameter of the bolt shaft.

- D3 (Patterns 1, 2, 5, and 6 only)

- The diameter of the tapered section of the bolt (pattern 1 and 2), or the diameter of the double-sided bolt (patterns 5 and 6).

- D4 (Patterns 2 and 4 only)

- Diameter of the washer.

- D5 (Pattern 6 only)

- Diameter of the double-sided washer.

- L1

- Length of the bolt head, excludes the thickness of the washer.

- L2

- Length of the main section of the shaft of the bolt.

- L3

- Transition zone between the tapered section of the shaft of the bolt and the main shaft of the bolt, or the length of the double-sided bolt head excluding the thickness of the washer (pattern 6).

- L4 (Patterns 1 and 2 Only)

- The length of the tapered section of the bolt (patterns 1 and 2), or the length of the double-sided bolt (pattern 5).

- L5

- The position of the pretension section.

- T (Patterns 2 and 4 only)

- The thickness of the washer.

- T1 (Pattern 6 only)

- The thickness of the washer.

- T2 (Pattern 6 only)

- The thickness of the double-sided washer.

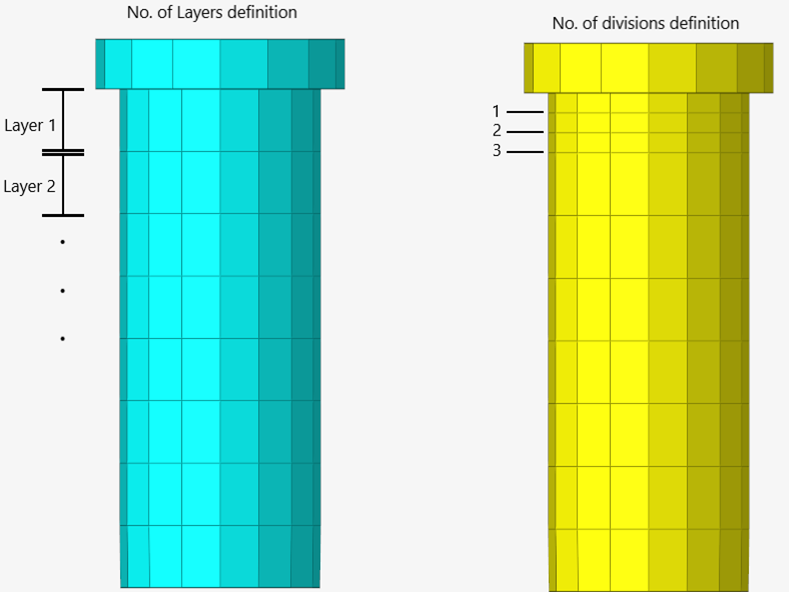

- Mesh Type

- Use this option to change between a Hex or a Tet Mesh for the bolt.

- Mesh Size

- Use this option to define the mesh size down the length of the bolt.

- Mesh Density

- Use this option to define the mesh density around the circumference of the bolt.

- Evaluation Surfaces

- Use this option to create finer mesh areas and element sets near the bolt head.

- Pretension

- An optional parameter that will create a pretension section.

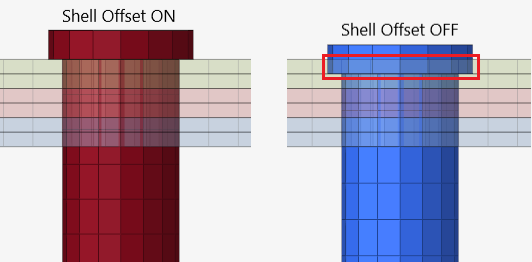

- Shell Offset

- Use this option to consider the thickness of shell elements when

calculating the bolt’s body length (L2). For patterns with a

double-sided head, the shell offset option applies to both sides.

Figure 8. Shell Offset option

- Cross Section

- Use this option to define the number of cross sections to be created down the bolt length.

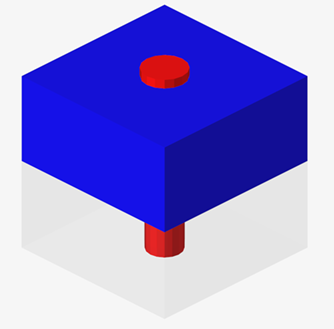

- Failure (LS-DYNA Only)

- This will create a layer of elements under the head of the bolt with

hour glassing and a rupture material so the failure of the bolt can be

modeled.

Figure 9.

- Rupture Material

- An optional selector that can be used to define an existing material for the failure elements. If left empty, a new material will be created for the realization.

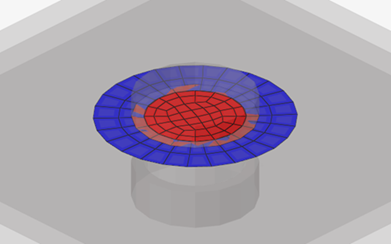

Contact

Contact is created for all solver profiles automatically.

- Explicit Solver Interfaces

- For explicit solver interfaces (LS-DYNA and

Radioss), there are no contact options.

The entire bolt and links are placed into a contact set. The shaft of

the bolt is tied into the last link.

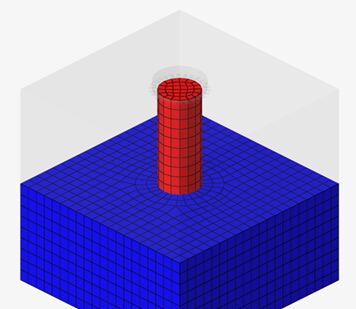

Figure 10.

Figure 11.

- Implicit Solver Interfaces

- For the Implicit solver interfaces (OptiStruct, Abaqus, and Nastran), under the head of the bolt is modeled separately as a contact. For

patterns with a double-sided head, contact is created for both

sides.

Figure 12.

- Shaft Contact Type: (OptiStruct/Abaqus/Nastran only)

-

- Tied

- A tied contact is created for the shaft of the bolt and the

last link of the connector.

Figure 13.

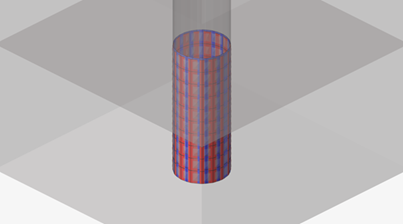

- Threaded (Solid Links Only)

-

- Last Part

- A contact patch will be created between the

inner face of the solid hole and the face of the

bolt shaft.

Figure 14.

- Contact Length

- Measured from the bottom of the bolt, the

contact thread on the bolt will be the specified

thread length.

Figure 15.