Create and Realize Connectors

Use the tools in the Create tool set to create connectors, assign controls, and realize.

-

Navigate to the Connectors ribbon then select any of the tools in the Create

tool set to define the associated connector type.

- Point

- Fastener

- Line

- Area

-

On the guide bar, click

to define connector options.

to define connector options.

- Use the selector on the guide bar to choose an entity type, then select features on which to create connectors.

-

Use the options in the microdialog to further define

the connector.

The following options are available for all entity types and tools.

Option Description Move/Morph (  )

)Relocate sections or the whole connector to a different position Link Edit (  )

)Opens a dialogue that allows you to adjust the link detection logic. Show/Hide Projections (  )

)Show and hide the pre-projections that indicate where the connector will connect to. Other options are dependent on the entity type and selected tool.Option Description Trim (  )

)Split the connector at a selected position. Available for node list, line, element, and surface selection.

Partition (  )

)Partition the seam connector if any part of that connector does not have projections. Only available for the Line tool.

Pitch and Density - Pitch (

)

) - Adjust the number of significant points along the connector line by given spacing.

- Density (

)

) - Adjust the number of significant points along the connector line by a number.

Available for node list and line selection in the Point and Line tools.

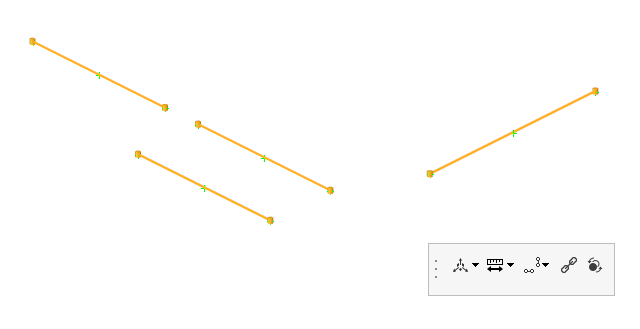

Line Interpolation - Straight line (

)

) - A straight interpolation line is created between the

selected nodes.

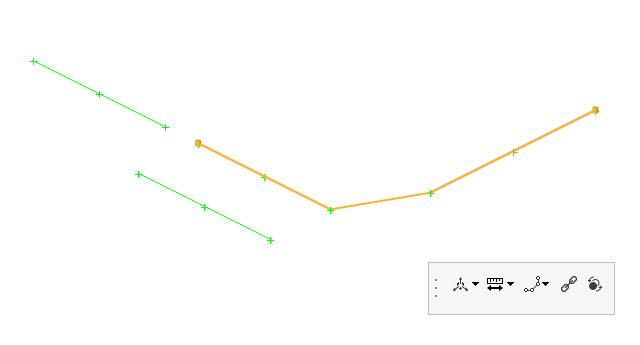

Figure 1.

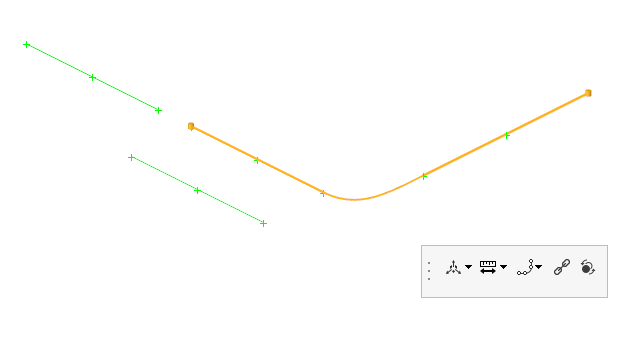

- Interpolated line (

)

) - A smoothed interpolation line is created between the

selected nodes.

Figure 2.

Available for node list selection in the Point and Line tools.

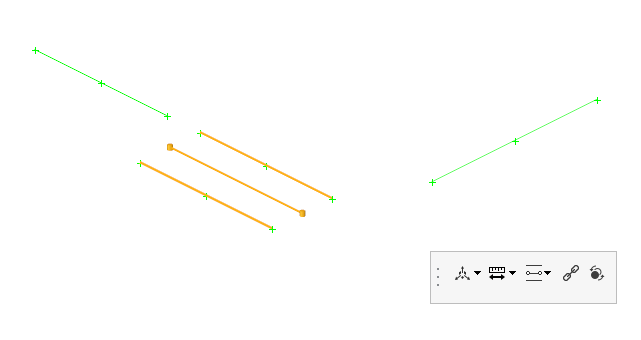

Line Creation - None (

)

) - Leave the line selections separate.

Figure 3.

- Combine Smooth (

)

) - Combine selected lines with an interpolated line.

Figure 4.

- Combine Straight (

)

) - Combine selected lines with a straight line.

Figure 5.

- Mid Line (

)

) - Generate a midline between selected lines.

Figure 6.

Only available for line selection.

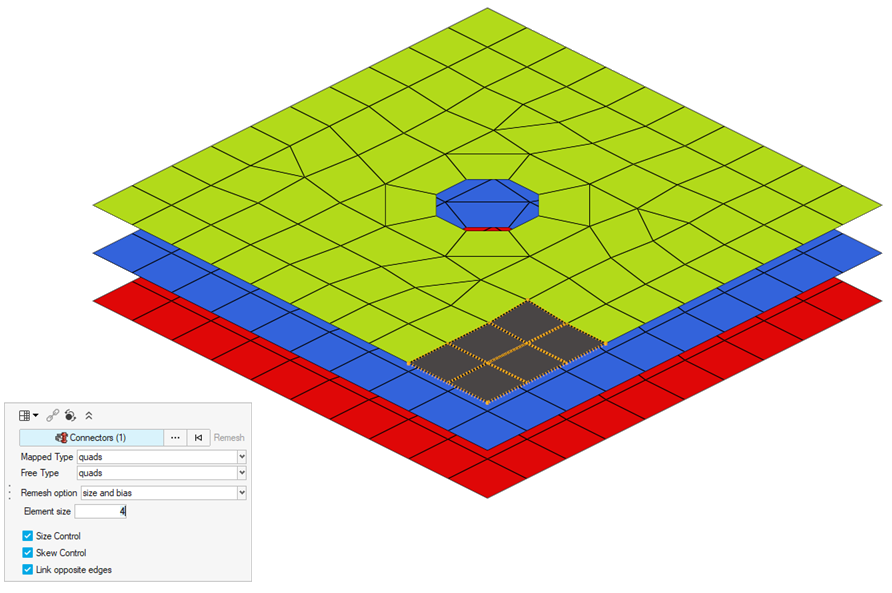

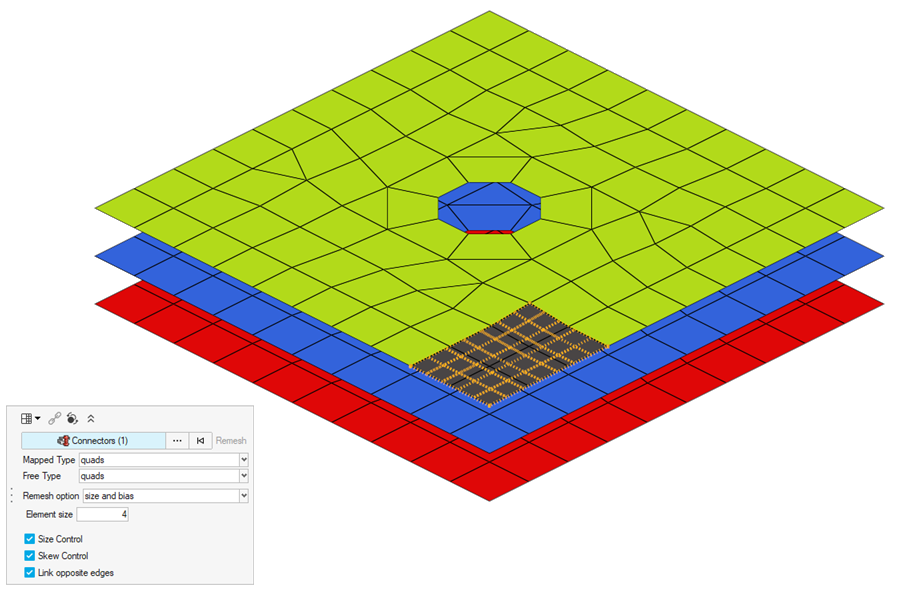

Remesh (  )

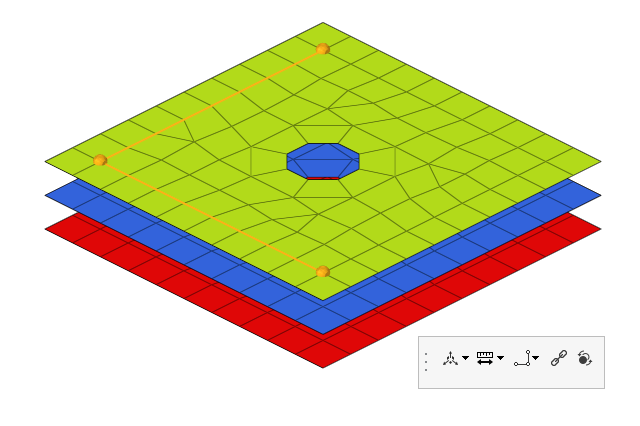

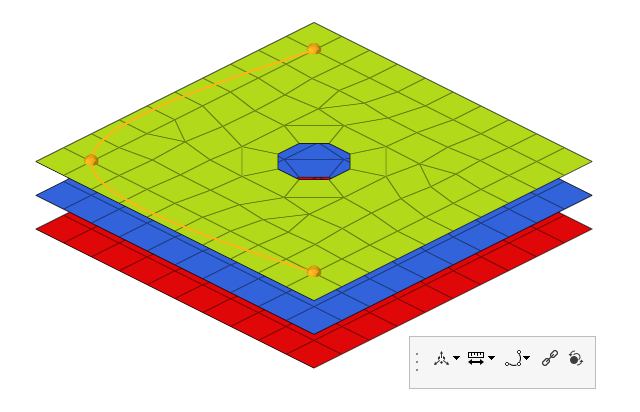

)Remesh the connector surface. Figure 7.

Available for any selection type in the Area tool.

- Pitch (

-

Use the drop-down menu on the guide bar to assign a

control to the connector.

Choose a previously defined control or click Create New to open the Control Manager and define a new control. If you select Undefined, the connector will be created without a control.

By default, an assigned control is realized.

-

On the guide bar, complete one of the following:

- Click

to apply and stay in the tool.

to apply and stay in the tool. - Click

to apply and close the tool.

to apply and close the tool. - Click

to exit the tool without applying.

to exit the tool without applying.

- Click