Motion

Introduction

The Motion allows you to define the motion of some bodies of the solution.

Dialog Box

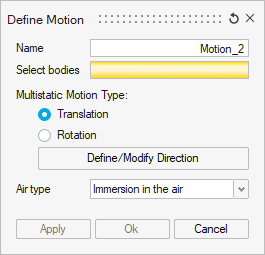

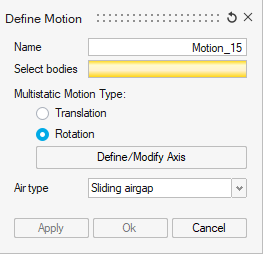

| Translation type motion | Rotation type motion |

|---|---|

|

|

- Select bodies which are moving. At least, one body must be selected.

- Multistatic Motion Type: Two choices

are proposed:

- Translation

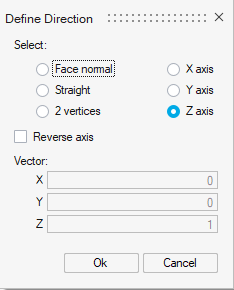

Translation direction has to be chosen through Define/Modify Direction button:

- Rotation

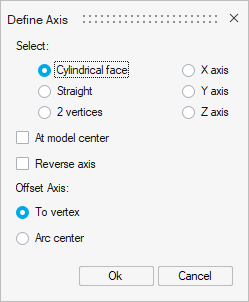

Rotation axis has to be chosen through Define/Modify Axis button:

- Translation

- Air type:

Two choices are proposed, available for both Translation and Rotation:

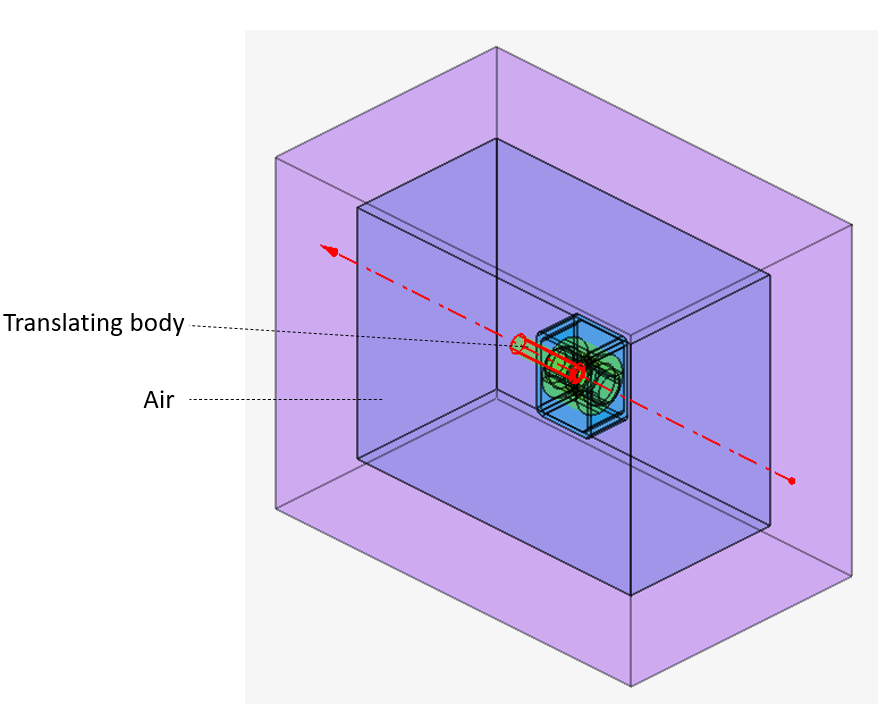

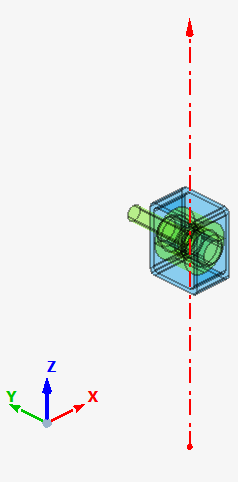

- Immersion in the air

This air type is chosen when the moving bodies are immersed into a large air volume.

The following example illustrates it:

It is mostly used for translating motion.

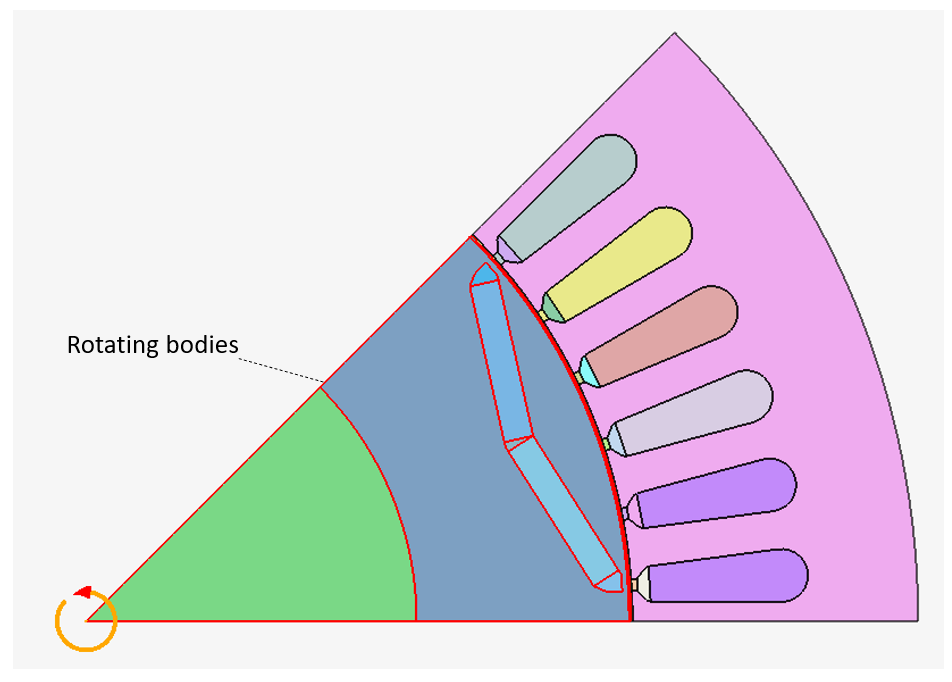

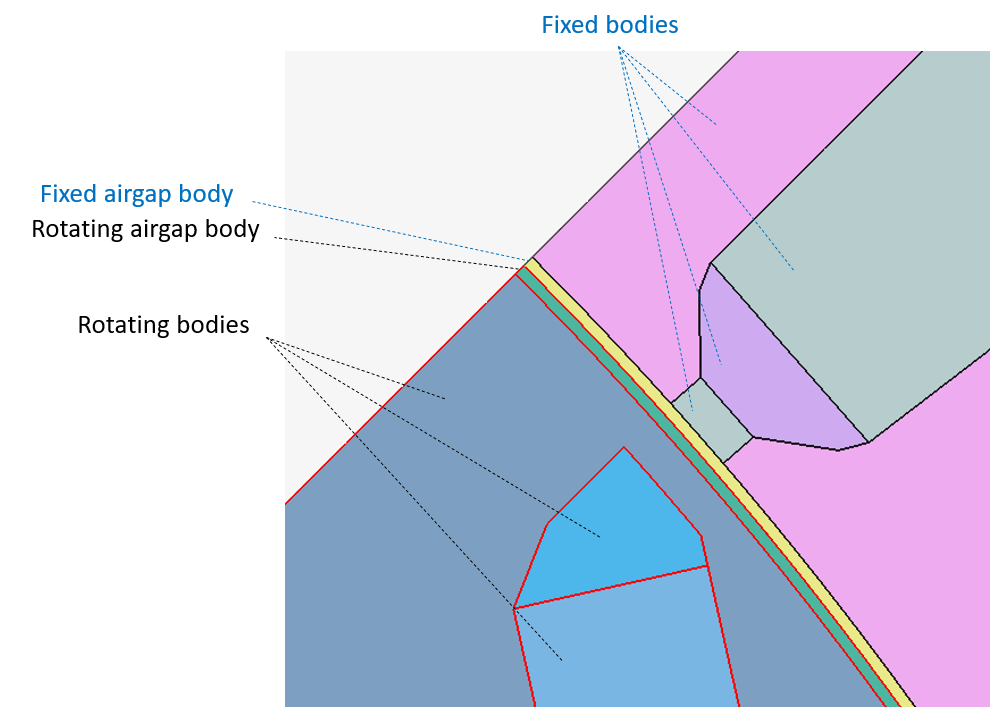

- Sliding airgap

This air type is chosen when the moving bodies are sliding with respect to the fixed part. The sliding surface is located inside the airgap and separates the airgap into two bodies: moving airgap and fixed airgap.

The following example illustrates it:Sliding airgap is mostly used for rotating motion, especially for motors.

- Immersion in the air

Motion parameters

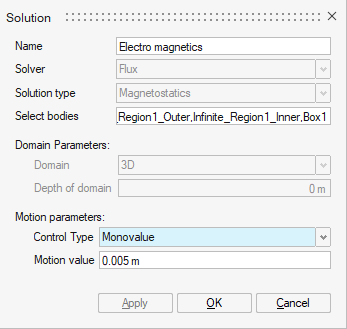

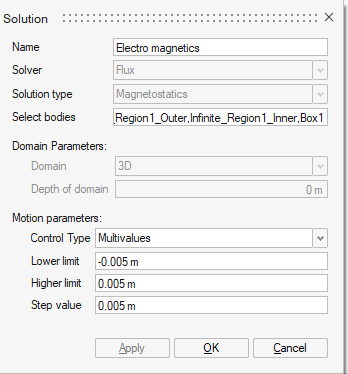

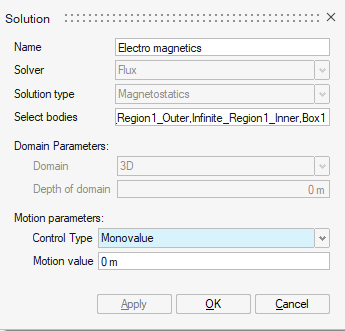

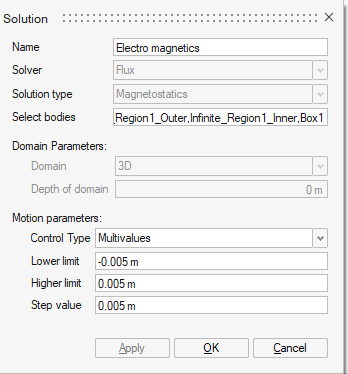

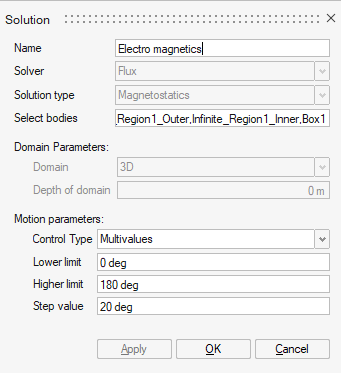

Once the motion entity is created, the Solution box content is updated with Motion parameters inputs to pilot the motion during the solving:

| Solution with Monovalue Motion parameters | Solution with Multivalues Motion parameters |

|---|---|

|

|

Monovalue Motion parameters allow to solve for one position defined by an offset distance or angle (respectively for translation and rotation) applied on the initial position.

Multivalues Motion parameters allow to solve for several positions defined by a Lower limit, a Higher limit and a Step value. Those values correspond to distance or angle offsets (respectively for translation and rotation) applied on the initial position.

Steps for Translation

In this section, we will show the steps for translation case on an example of linear actuator:

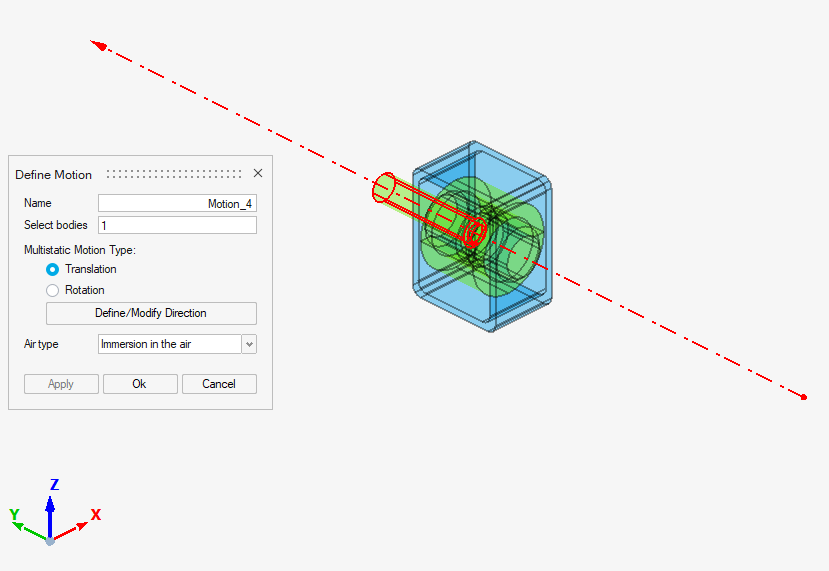

-

Click on the Motion button:

→ A default direction of the translation with an arrow on Z is visible at Motion box opening. This will be changed in following steps.

- Select bodies which are moving.

In this case, the body highlighted in red in the upper image.

→ The selected bodies are highlighted, and the corresponding field in the dialog box is filled with selected bodies names.

- Select Multistatic motion type as Translation

- Open Define/Modify Direction.

Select Y axis and OK.

→ The preview of the translation direction is correctly updated.

- Check that Air type is set to Immersion in the air (default choice for Translation).

-

Click on Ok.

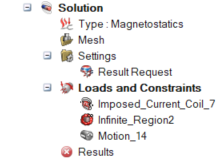

→ The Motion is created and appears in the Solution Browser (2nd tab) in the node Loads and Constraints

-

Once the motion entity is created, the motion has to be piloted for the solving. This has to be done in the Solution box which contains now Motion parameters inputs.

-

Click on the Edit solution button:

→ The solution box contains now Motion parameters inputs with by default Monovalue control type set to 0.

-

We will choose for this example Multivalues motion parameters to solve at different positions.

- Select Control type: Multivalues

- Enter Lower limit distance value

- Enter Higher limit distance value

- Enter Step value distance value

- Click on OK

→ The project is ready to be solved.

-

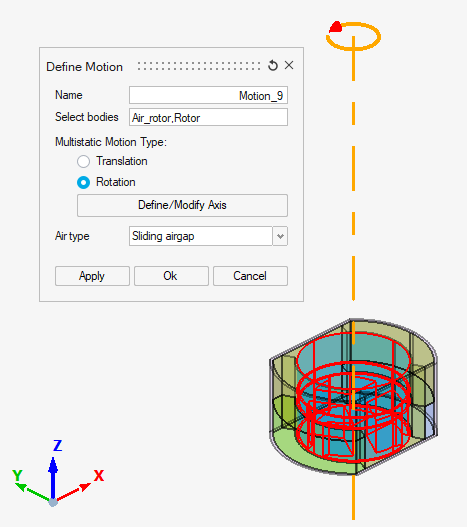

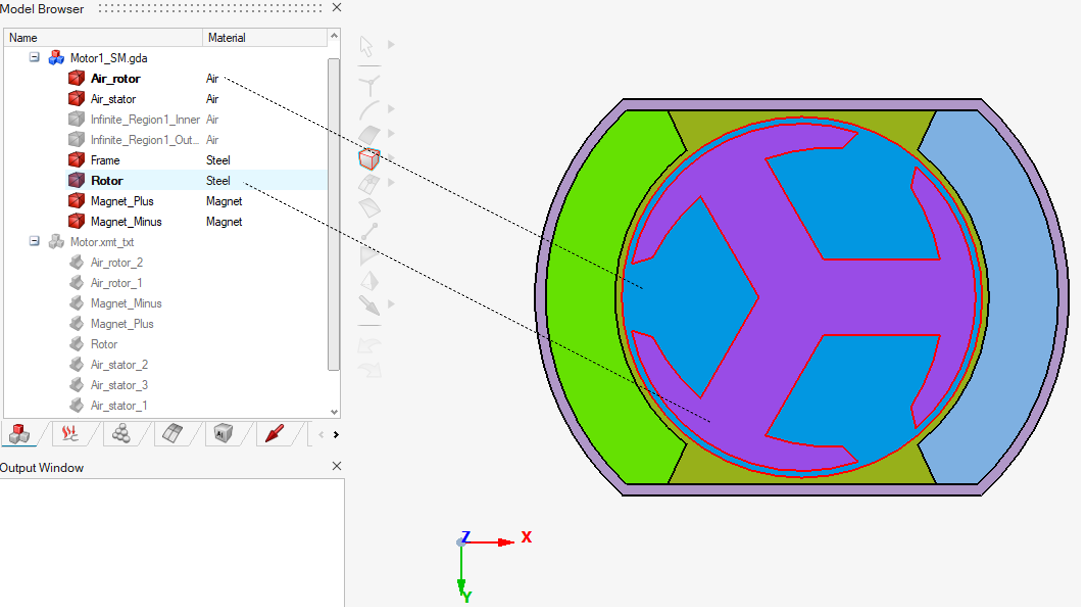

Steps for Rotation

In this section, we will show the steps for rotation case on an example of a rear-view motor:

-

Click on the Motion button:

- Select bodies which are moving. In this case, the

bodies "Rotor" and "Air_rotor" highlighted in red in the following image are

selected. "Air_rotor" corresponds to the moving airgap part (it is touching

the body "Air_stator" on the sliding surface).

→ The selected bodies are highlighted, and the corresponding field in the dialog box is filled with selected bodies names.

- Select Multistatic motion type as

Rotation

→ The preview of the default rotation axis is displayed (Z axis) which is the right one on this example.

- If needed, it is possible to open Define/Modify Axis to select another rotation axis.

- Check that Air type is set to Sliding airgap (default choice for Rotation).

-

Click on Ok.

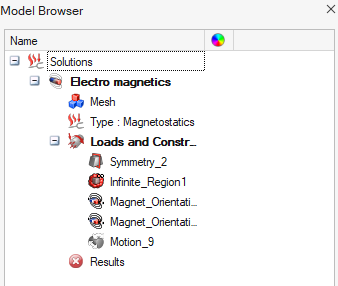

→ The Motion is created and appears in the Solution Browser (2nd tab) in the node Loads and Constraints

-

Once the motion entity is created, the motion has to be piloted for the solving. This has to be done in the Solution box which contains now Motion parameters inputs.

Please follow Step 7 of Steps for Translation and enter the angular offset positions (in degree) to be simulated.

→ The project is ready to be solved.

Advices

- In the use case of Immersion in the air air type (mostly for Translation use case), it is advised to reduce as much as possible the surrounding air body size. In fact, as this body is remeshed in Flux at each moving step, reducing its size will reduce memory storage requirements and solving time.

- In the use case of Sliding airgap air type (mostly

for Rotation use case), it is important that the

areas of face to face surface elements be approximately the same for any

rotating angle. This is illustrated in the figures below.

Recommended meshing Non-recommended meshing (inhomogeneous density of nodes along the two circumferences)

Limitations

- In this version: Only one motion entity can be created in a solution.

- In this version: In the use case of Immersion in the air air type (mostly for Translation use case), the contact between the fixed device bodies (except surrounding air body) and moving bodies is forbidden. In consequence, user must choose carefully the motion parameters values in the solution box to keep a gap between the moving bodies and the fixed bodies for all solving steps.