Sheet Lamination

Introduction

The Sheet Lamination allows to define stacked magnetic sheets and allows to compute iron losses in Transient and AC analysis (only Bertotti model at this time).

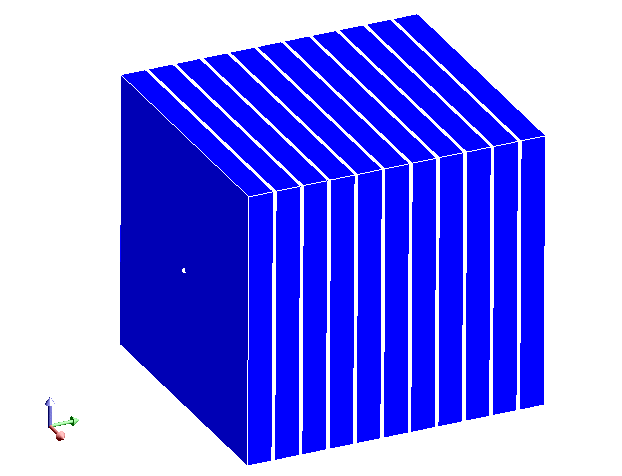

This Load enables the modeling of a laminated part: magnetic (permeability μr) non conducting, like stacked magnetic sheets simplified via the homogenization method.

With Sheet lamination load, there is not need to represent geometrically each sheet.

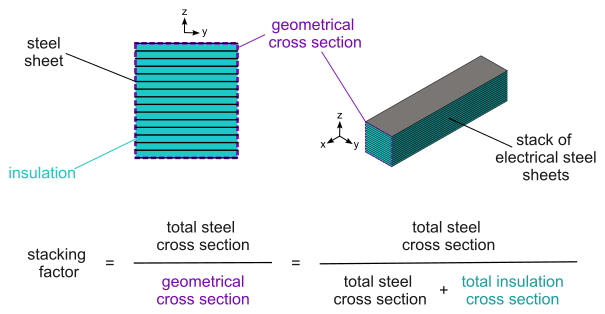

- a stacking factor:

The sheet lamination is said to be laminated because it automatically accounts for the effect of the insulation of the electrical steel and for the small air gaps between the sheets in a stack. This is achieved through a homogenization procedure implemented. The overall effect of this homogenization is that the effective cross-section of magnetic material available for the magnetic flux to traverse in the region is reduced. The reduction factor is known as the stacking factor of the region, and corresponds to the total cross section area occupied by magnetic material (steel) in the stack divided by the surface area of the geometrical cross section of the same stack (i.e., the total cross section area, including the insulation and air gaps between sheets). This definition is illustrated below:

Iron losses - principle

Magnetic losses (or iron losses) computation is an a posteriori computation, carried out in post-processor.

- the magnetic losses in the magnetic circuits (also called ‘iron losses’)

- the losses by Joule effect in coils (also called ‘copper losses’)

- the mechanical losses (mainly by friction in rotating machines)

Losses in magnetic materials:

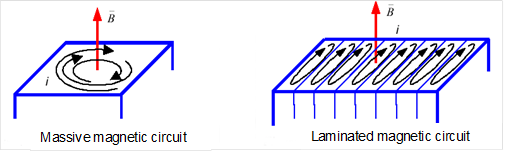

- The hysteresis losses (microscopic Eddy currents) are associated to currents at a small scale. These currents are the result of local flux density variation caused by the magnetic structure in movement (essentially wall movement).

- The Eddy losses (macroscopic Eddy currents), are due to the excitation frequency. They appear when domain wall displacement increases due to frequency increase.

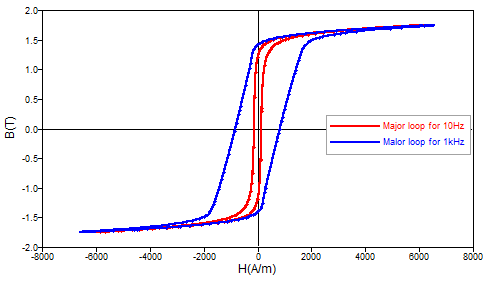

Magnetic losses and hysteresis cycle:

- the volume energy created by hysteresis losses is corresponding to static hysteresis cycle (f<1Hz).

- as the frequency increases, the cycle area increases and the volume energy created by Eddy current losses is corresponding to the difference between the dynamic hysteresis cycle area and the static one.

Iron losses computation in SimLab

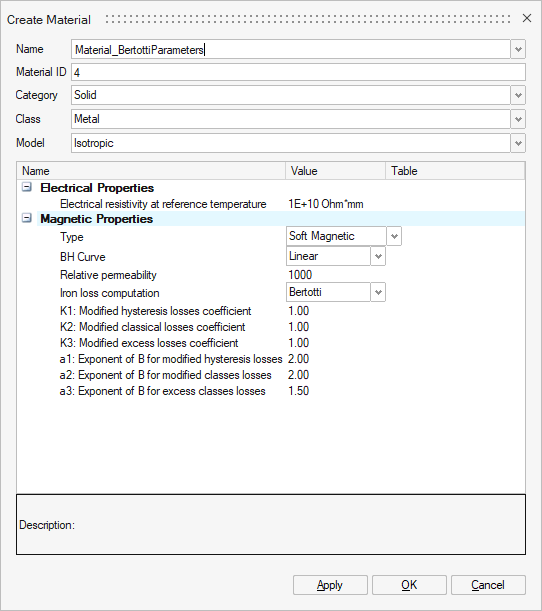

To be able to compute the iron losses in SimLab, the material assigned to the body defined by a sheet lamination load should be a soft magnetic material with 3 coefficients and 3 exponents of Bertotti Model.

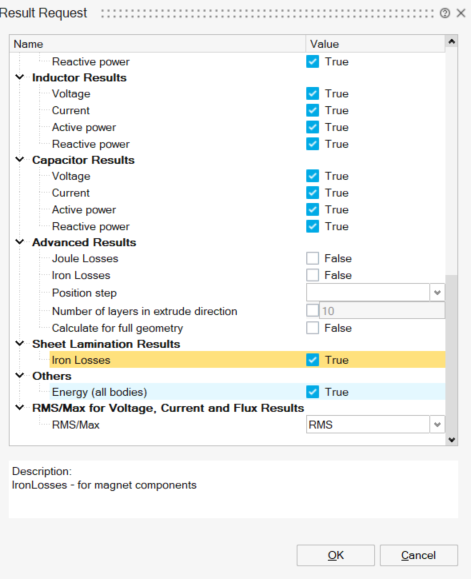

- For 2D and 3D AC Magnetic solutions, in

Result Request, in Sheet Lamination

Results node, you should choose True

for Iron Losses computation.

Modified Bertotti model for 2D and 3D AC Magnetic solutions

With the modified Bertotti model, the iron loss density (directly related to the specific losses by the mass density) in a stack of electrical steel sheets may be decomposed in a sum of three terms: namely hysteresis, classical (also called eddy current) and excess losses terms. In each point of the material described by a laminated magnetic non conducting region, in the frequency domain the following equation holds:

represents the mean iron loss density, in W/m³;

- is the stacking factor of the lamination;

- is the hysteresis losses coefficient;

- is the hysteresis losses exponent;

- is the classical losses coefficient;

- is the classical losses exponent;

- is the excess losses coefficient;

- is the excess losses exponent;

- is the frequency of the magnetic flux density, which is supposed to vary periodically in time;

- (in teslas) is the maximum magnitude that the homogenized magnetic flux density can reach in the considered point of the laminated region over a period ; this value is automatically computed by Flux through the magnetic flux density and the stacking factor .

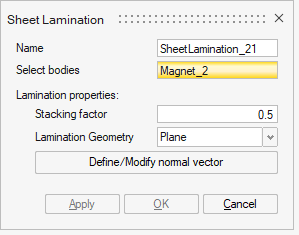

Sheet Lamination Dialog Box for 3D Transient Magnetic, 3D AC Magnetic, and 3D Magnetostatic solutions

- Select bodies: one or several bodies to define as sheet lamination.

- Lamination properties:

- Stacking factor

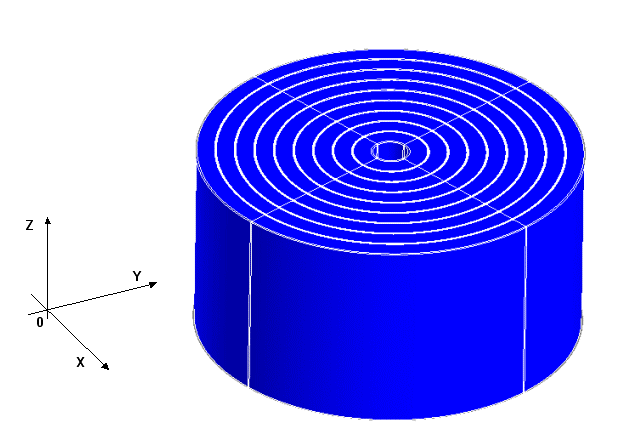

- Lamination Geometry2 types:

- Plane

The direction of the planar sheet lamination is defined by a normal vector, by clicking on Define/Modify normal vector

- Cylinder

The direction of the cylindrical sheet lamination is defined by the cylinder axis, by clicking on Define/Modify cylinder axis

- Plane

Steps

- Check the prerequisites:

-

a Soft Magnetic Material should be assigned to the body. To compute the iron losses in transient and AC analysis, the Bertotti parameters should be defined.

-

- Click on the Sheet Lamination

button in Analysis ribbon:

- Select bodies: Select one or several bodies to define as a sheet lamination.

- Choose the Stacking factor

- In 3D, define the Lamination Geometry

- Validate by clicking on OK

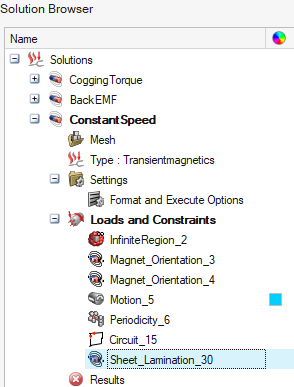

→ The sheet lamination is created and appears in the Solution Browser in the Loads and Constraints node.

-

To compute the iron losses in Transient and AC analysis: before solving, edit Result Request and define the Sheet Lamination Results

-

Choose True for the Iron Losses

-

Validate by clicking on OK

-