The Powders Database

The EDEM Powders database is a collection of pre-calibrated EDEM material models for powders.

These material models capture the complex bulk behaviour of powder materials while using up-scaled numerical particles. This ensures practical solution times when simulating full scale industrial processes described in the works of Thakur, S. C., Morrissey, J. P., Sun, J., Chen, J. F., & Ooi, J. Y. (2014).

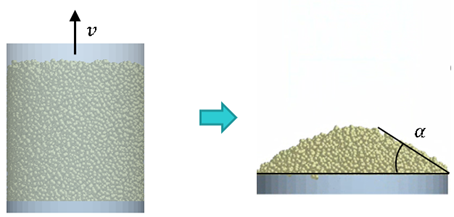

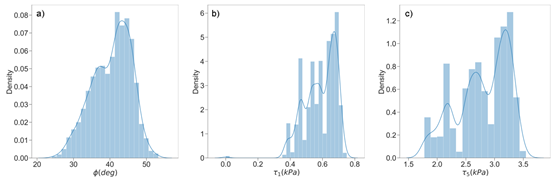

Models that capture the poured bulk density, static angle of repose described in Standard Test Method for Bulk Solids Characterization by Carr Indices, ASTM International, West Conshohocken, PA, 2021, steady state shear stress measured in direct shear described in Standard Test Method for Shear Testing of Bulk Solids Using the Jenike Shear Tester, ASTM International, West Conshohocken, PA, 2016 and the works of R. Freeman FT4 Basic Flowability Energy (BFE) described in Measuring the flow properties of consolidated, conditioned and aerated powders - A comparative study using a powder rheometer and a rotational shear cell, Powder Technol. 174 (2007) 25–33 are included in the database.

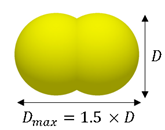

The two-sphere particle shape shown in Figure 2 and the normal relative particle size distribution described in the tables are adopted in order to capture shear dilation effects and avoid non-physical packing states described in the works of Härtl, J.Y. Ooi. The standard particle diameter D50 in the database is 1.5 mm, but the values between 0.2 and 5 mm are available for the direct shear response where particle size and density scaling laws are applied to maintain the behaviour constant over a range of sizes described in the works of Thakur, S. C., Ooi, J. Y., & Ahmadian, H. (2016).

| Particle Size Distribution | |||

|---|---|---|---|

| Type | Dmin/D50 | Dmax/D50 | ơ/D50 |

| Normal | 0.85 | 1.15 | 0.15 |

| Fixed Parameter Space | |

|---|---|

| Particle Poisson’s ratio v | 0.25 |

| Particle Shear Modulus G (Pa) | 1e+7 |

| Particle solid density ρs (kg/m3) | 1000 |

| Particle coefficient of restitution e | 0.1 |

| Particle – Geometry coefficient of static friction μg | 0.5 |

| Particle – Geometry coefficient of rolling friction μrg | 0.1 |

| EEPA tangential stiffness multiplier ktan | 0.667 |

| EEPA loading exponent n | 1 |

| EEPA tensile exponent kadh | 3 |

| Variable Parameter Space |

|---|

| Particle – particle coefficient of static friction μs |

| Particle – particle coefficient of rolling friction μr |

| EEPA constant pull-off force f0 |

| EEPA surface energy γ (J/m2) |

| EEPA contact plasticity ratio λ |

The database can be searched per response, and the results are sorted based on the relative error between the requested response values and the database results.

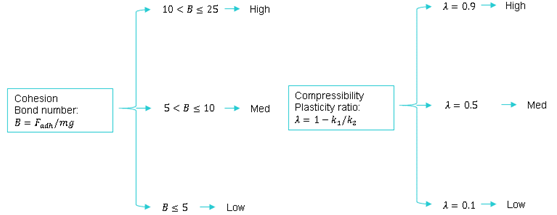

- The bulk cohesion and compressibility, which are qualitatively categorized using

the bond number and the EEPA contact plasticity ratio respectively.

- The bulk density, which is captured via particle solid density and Bond number scaling of the baseline values, and has variable ranges for the different bulk cohesion levels.

- The mean particle diameter (direct shear response only).

- The target value of the response of interest.