The GEMM Material Wizard

You can access the rich material information in the GEMM database to explore example materials and get input decks for use in their EDEM simulation.

-

In the Creator Tree, right-click the Bulk Material or

Equipment Material section and select Open

GEMM Wizard.

Note: The GEMM Database contains only Multi-Sphere models. - On the Welcome screen, select the Search by Material Properties option and click Next.

-

Answer the following questions on the particle Bulk Material behavior:

- What scale is your application?

The GEMM Database comprises numerous material sets that are intended to cover a wide range of material sizes. Each has a size distribution centered on a median value.

Start with the largest size and test it on the application if you are unsure about the size distribution. Working with a test case in which the particles are too large is faster than working with a scenario in which the particles are too small. Since the particle count is lower in a large size material, the simulation progresses faster. If the particles are too small, the time it takes to fill a volume can be slowed instead of moving with the simulation.

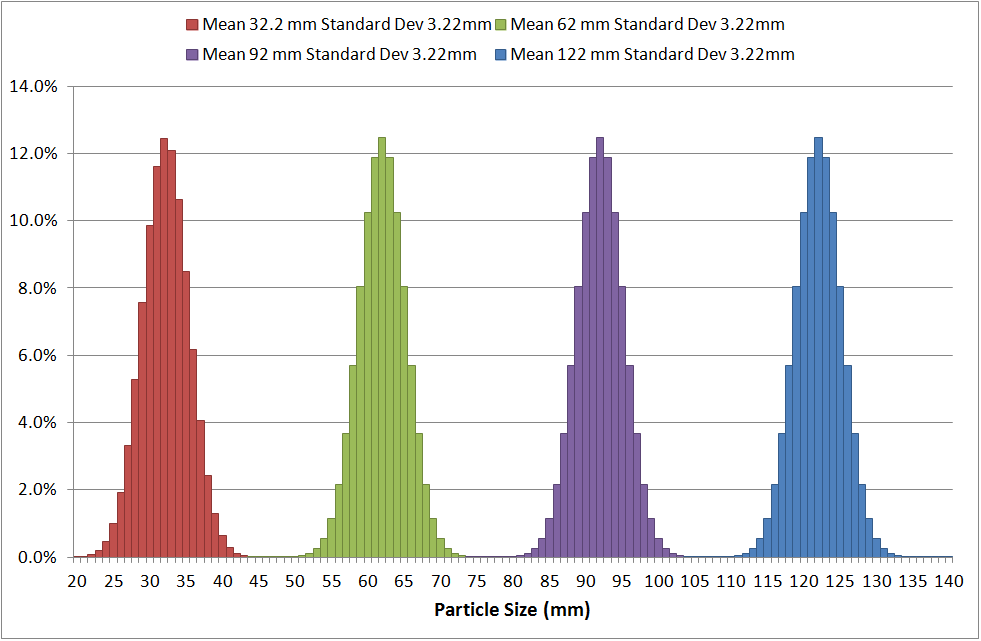

The actual size ranges used in the GEMM database are:

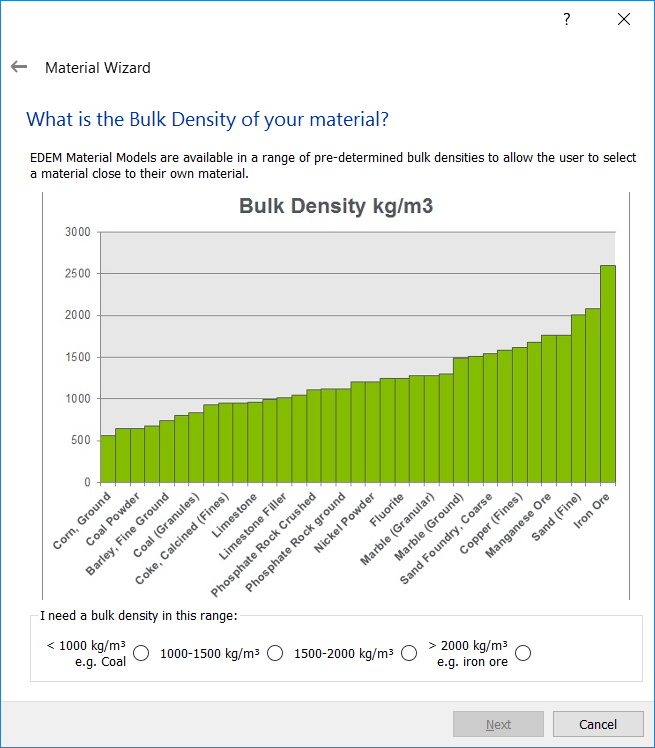

- What is the Bulk Density of your particle

material?

Material Bulk Density is the mass of the material (+ moisture content)' / 'volume of the material as a whole':

- If the interface allows you to select a material's Bulk Density from a list.

- If the real particle material's Bulk Density is close to the

margin of one of the ranges, you may adjust it after the

material file is generated.

You can use the provided GEMM material as a starting point for a small study with variations in the material solids density if a closer match to the bulk density is necessary.

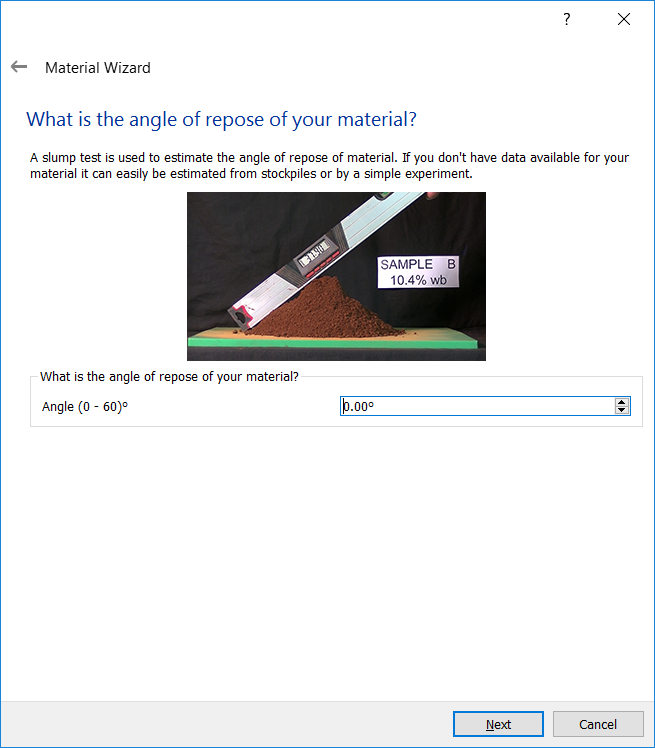

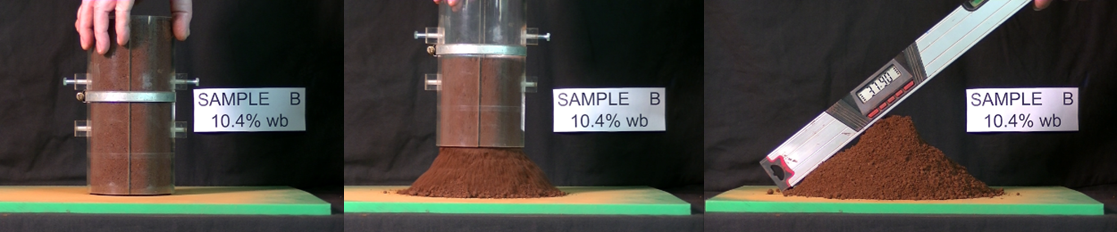

- What is the angle of repose of your material?The angle of repose is a frequently used measure of material that appears in standard test data. Even though such information is not included in current material data reports, it can still be measured in a fairly simple manner without specialized tools (for example, by monitoring the angle of a stockpile). Finally, it is a quantity that is relatively simple to estimate using engineering expertise if there is no access to any testing reports or on-site data.

Note: Because measuring an angle of repose with great accuracy is difficult, it is usually viewed as an approximation to the material behavior rather than describing it completely. As a result, the GEMM Database material model should be used as a guide or starting point, and you should be aware that changes in behavior may still exist.The angle of repose test is demonstrated in the following example:

The angle of repose has a maximum value of 60 degrees in the GEMM database, and any materials with angles greater than this should be calibrated separately. The smallest angles are between 20 and 30 degrees.

-

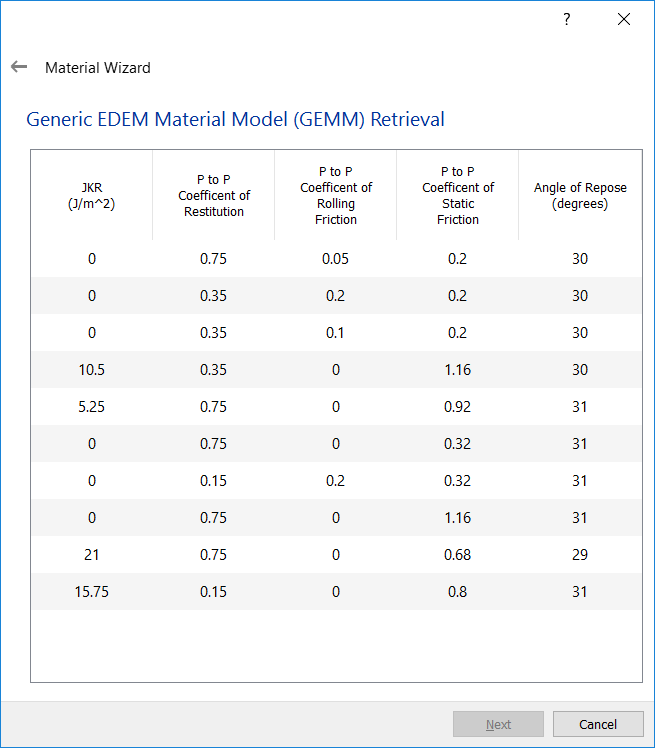

After you have answered these three questions, a list of ten materials that are the closest matches based on your responses is displayed.

Note: You can select one of these materials.- The top material corresponds to the input angle of repose the best. You can, however, choose different materials from the list.

- The Particle to Particle values of Restitution, Static Friction, and Rolling Friction are referred to as P to P.

- The JKR number represents the material's cohesive energy. Even if both materials have the same angle of repose, a sticky substance will have a greater JKR value than a non-sticky material.

- To avoid overly damped simulations, high JKR cohesion

values should be matched with larger coefficients of

restitution.

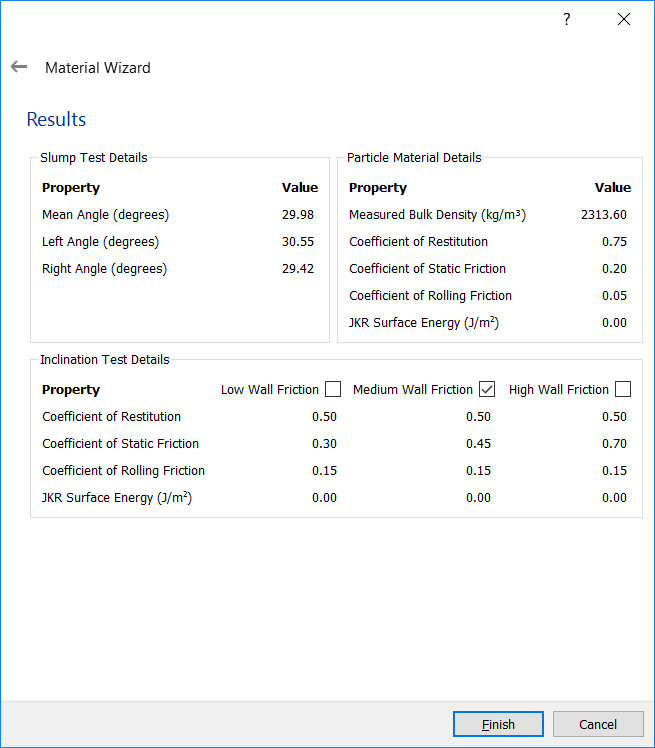

Once you have selected a material, the material details including the measured material Bulk Density value are provided.

Alternatively, to retrieve bulk material that you have already searched for, select Search by Material Name and specify the ID number of the GEMM material.

- What scale is your application?

-

Select any of the Equipment Interactions for this material:

- Low Friction

- Medium Friction

- High Friction

-

Select Finish to add the Bulk Material to the

simulation.

This material is added to the following areas:

- Bulk Material

- Properties

- Shape

- Size Distribution

- Interactions (Bulk Material - Bulk Material and Bulk Material - Equipment Material)

Medium friction is designed around a material such as Steel and Material friction is based on an Inclination Test.

A sample of the Bulk Material is placed on a flat plate, which is subsequently inclined until the material slides. A low Bulk Material Angle of Repose will slide at a lower inclination angle than a high Bulk Material Angle of Repose. As a result, the Bulk Material is classified as Low Angle (less than 35 degrees), Medium Angle (more than 35 degrees but less than 45 degrees), and High Angle (greater than 45 degrees).

The Geometry Interactions are then provided using the following table:Material Type Geometry Type Static Friction (p-g) Rolling Friction (p-g) JKR Cohesion (p-g) Inclination Test Results (average results) Low Angle Low Friction 0.3 0.15 0 21 Low Angle Medium Friction 0.45 0.15 0 27 Low Angle High Friction 0.7 0.15 0 34 Medium Angle Low Friction 0.45 0.15 0 28 Medium Angle Medium Friction 0.7 0.15 0 35 Medium Angle High Friction 1 0.15 0 39 High Angle Low Friction 0.7 0.15 0 37 High Angle Medium Friction 1 0.15 Low 46 High Angle High Friction 1.7 0.15 High 49