Topology Optimization: Example

Introduction

This page showcases two distinct types of electrical machines—a Permanent Magnet Synchronous Machine (PMSM) and a Switched Reluctance Machine (SRM)—to illustrate the innovative geometries achievable through Magneto-mechanical Topology Optimization. For each example, we provide the optimization setup and compare the resulting geometry and torque both before and after the optimization process.

Note: Please note that these two Magneto-mechanical optimization

examples are presented for demonstrative purposes only and should not be considered

representative of realistic designs or production-ready solutions.

Synchronous Reluctance Machine (SRM)

| Objective/Constraint | Response/Constraint type | Definition |

|---|---|---|

| Objective | Compliance | Minimize |

| Constraint | Von Mises stress | Up to 260 MPa (i.e., a percentage of the yield strength value of B M330 35A the electric steel used in the rotor) |

| Constraint | Mass fraction | Mass fraction range between 0.75-0.85 (of the initial design space body) |

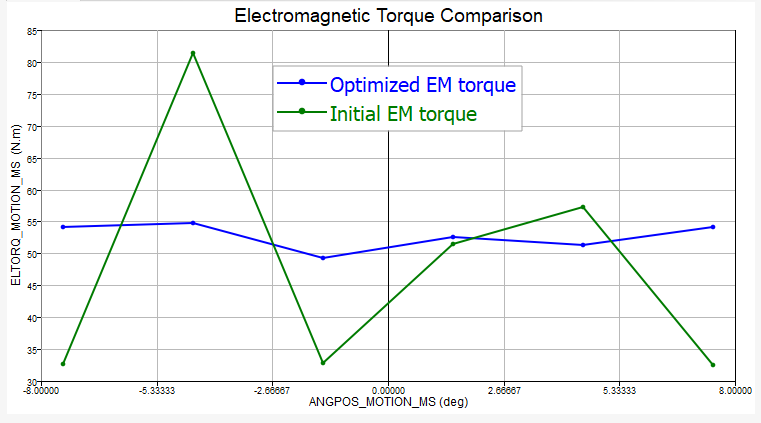

| Constraint | Average electromagnetic torque | At least 55 Nm (i.e., average electromagnetic toque of the studied electrical machine) |

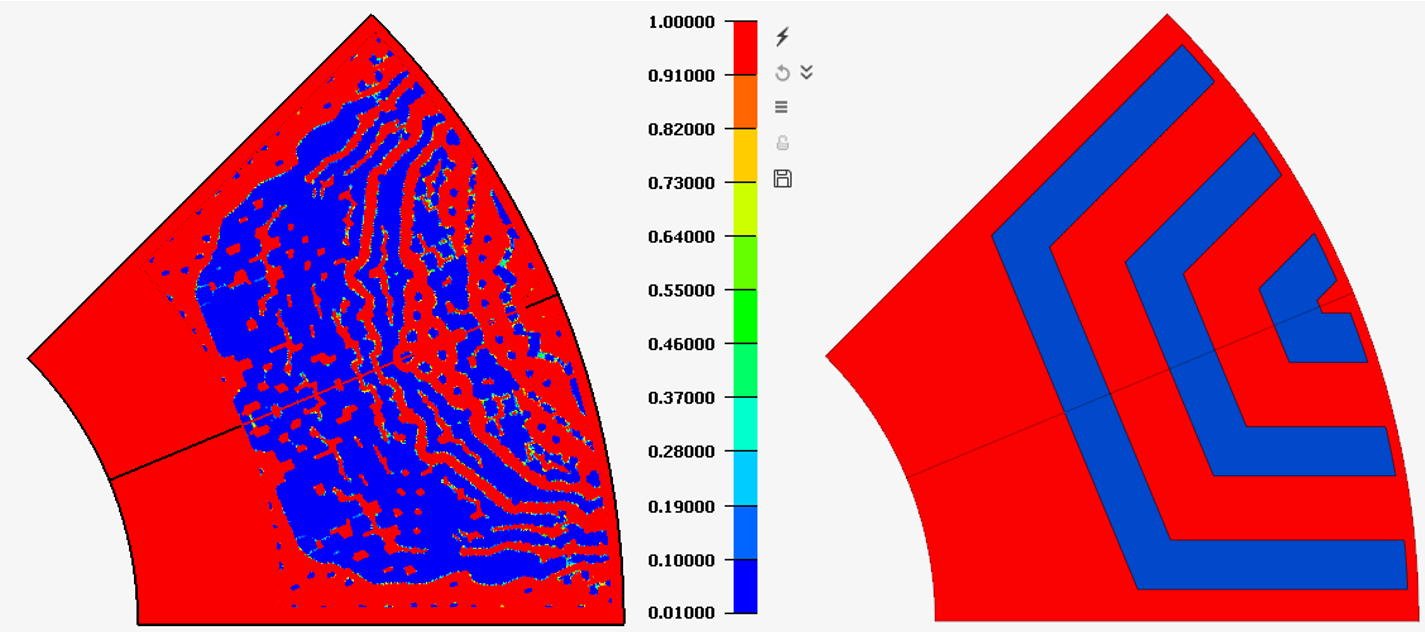

Geometry before (right) and after (left) optimization process (SRM)

Electromagnetic Torque before and after optimization process (SRM)

Permanent Magnet Synchronous Machine (PMSM)

| Objective/Constraint | Response/Constraint type | Definition |

|---|---|---|

| Objective | Compliance | Minimize |

| Constraint | Von Mises stress | Up to 250 MPa (i.e., a percentage of the yield strength value of the electric steel COGENT M270 35A 50HZ used in the rotor) |

| Constraint | Volume | At least 0.85 of the initial design space body volume |

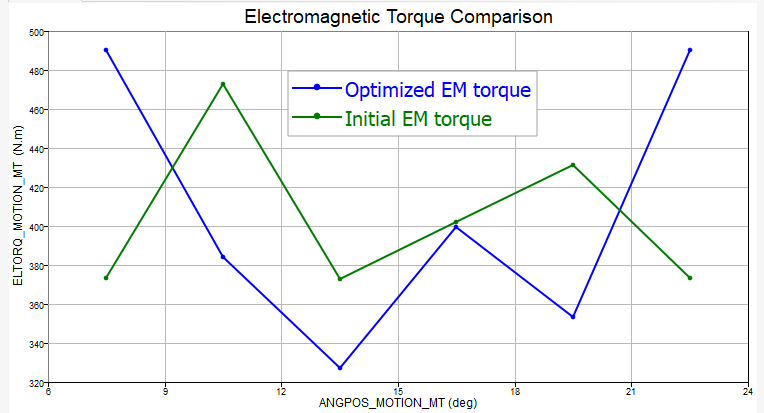

| Constraint | Average electromagnetic torque | At least 41 Nm (i.e., average electromagnetic toque of the studied electrical machine) |

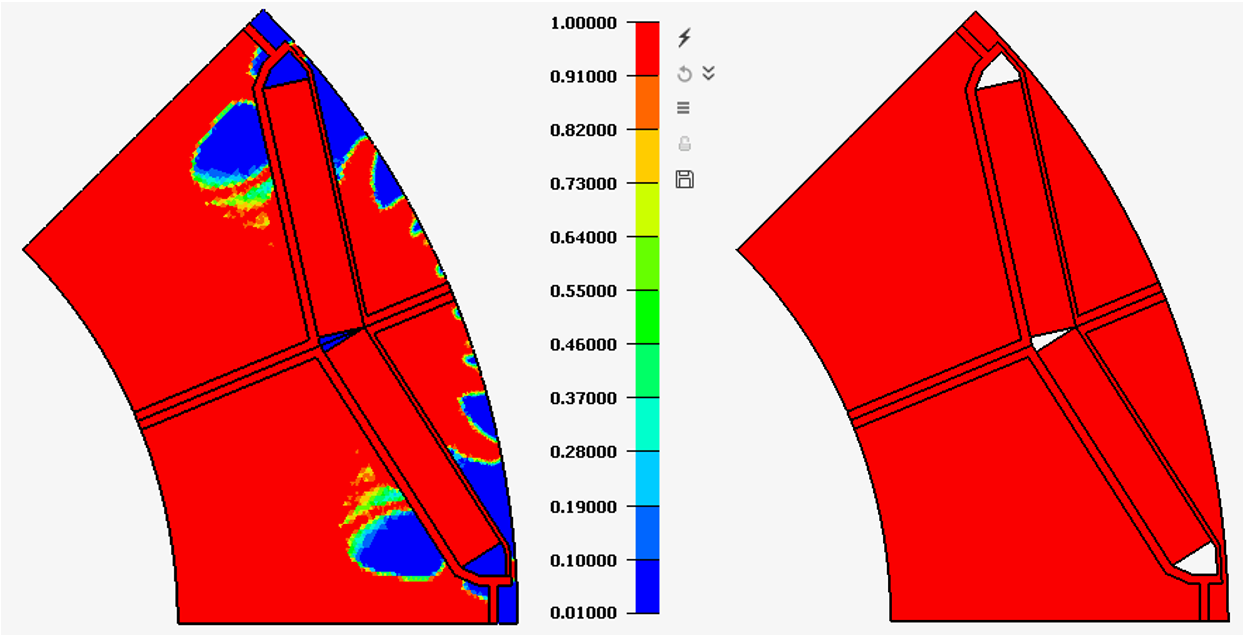

Geometry before (right) and after (left) optimization process (PMSM)

Electromagnetic Torque before and after optimization process (PMSM)

Remarks

For both examples, the initial rotor was segmented into multiple parts. This

strategic division offers two key advantages:

- It significantly reduces the overall design space, thereby simplifying the optimization problem.

- It constrains the Magneto-mechanical Topology Optimization to be applied specifically to those critical regions of the rotor that are essential for generating electromagnetic torque.