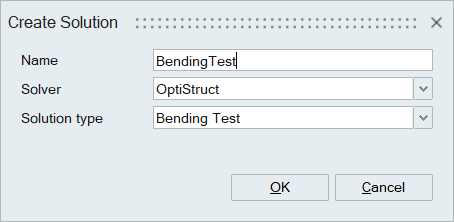

Bending Test

![]()

Description

Bending testing is widely used to determine the ductility and toughness of materials. Ductility refers to the material’s ability to plastically deform without fracturing, while toughness measures the material’s resistance to impact fracture. In this test, a sample of the material is subjected to bending forces until failure occurs.

The objective is to determine the ability of the material to withstand bending without fracturing. The objective is to analyse the stresses and displacement of the Part or assembly when it is pressed by pressing cylinder from top and constrained by the fixed cylinder at the bottom.

The assembly containing all the parts inside is subjected to bending using pressing cylinder. The parts are given appropriate contacts and material. The lower cylinders are fixed, the Part/Assembly is resting on it and the pressing cylinder is given Force or Displacement.

Method:

- Today, for Radioss solver, Three and Four-point bending are supported, the solving technique is Explicit.

- For OptiStruct, Three and Four-point bending are supported the solving technique is Implicit (Non-linear Static).