Flow

![]()

Flow Solution(SPH) is used to analyse chaotic fluid flow problems using the solver nanoFluidX. It is used to predict fluid flow around complex geometries with complicated motion. Applications include oiling within ICE or EV drivetrain systems, fuel sloshing and filling, and vehicle water management.

It enables engineers to optimize efficiency by reducing friction or heat losses, improve reliability and safety, while limiting mechanical stress and hot points, or reduce fatigue.

The nanoFluidX solver is optimized for use on Linux GPU systems and is extremely fast. For typical drivetrain applications, simulations can run an order of magnitude faster than a finite volume code without the need to simplify geometries.

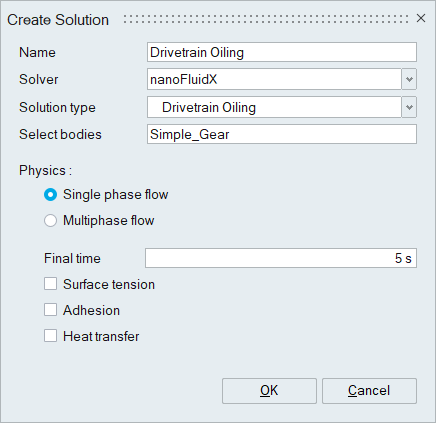

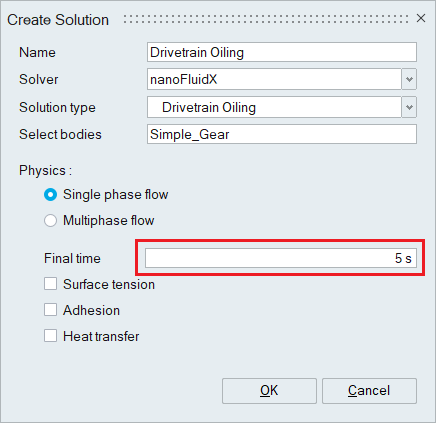

A variety of physics is supported including interaction schemes, surface tension, adhesion, Heat transfer and moving bodies. You need to select the required physics to be solved in the Solution panel. Accordingly, boundary conditions, solution parameters, material creation and assignment will be setup to run a simulation.

Tandem Interpolation

Solution type

Three types of solution types are supported.

Drivetrain Oiling

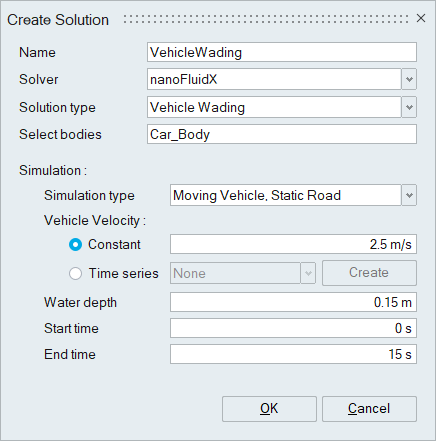

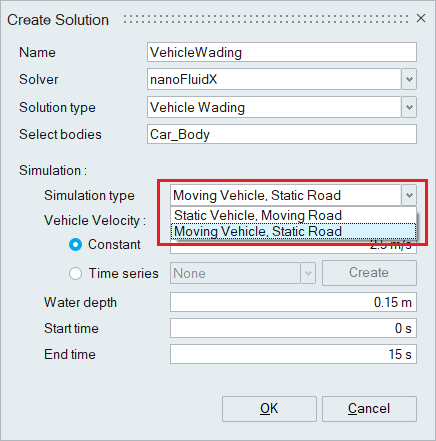

Vehicle Wading

This solution is designed for simulating vehicle wading through deep water. These simulations are characterised by a complex geometry interacting with a free surface fluid. Vehicle wading simulations in nanoFluidX are always single-phase simulations.

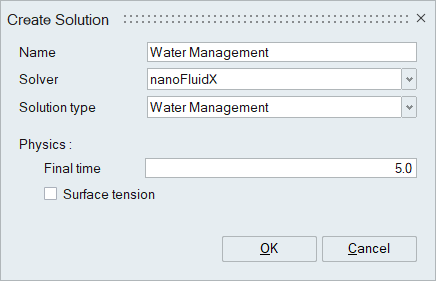

Water Management

This application is used to simulate a variety of use cases with a focus on directing water flow, water reach, etc. Supports Shower generation along with efficient 1-click particle generation.

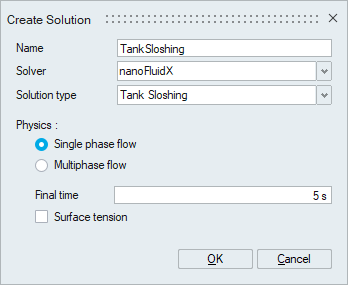

Tank Sloshing

Tank sloshing is the transient movement of liquids within a confined container or tank. This phenomenon is common in various modes of transportation and storage, including vehicles, cargo ships, trains, aircraft, and shore oil tanks. Tank slosh occurs when the liquid inside the container or tank experiences forces that cause it to move around.

Select bodies

Select the bodies to be included in the simulation. Only the bodies selected will be used for the simulation, even though there are more bodies in the SimLab database. Currently CAD bodies are not supported in the solution, only tessellated/meshed FEM bodies are permitted.

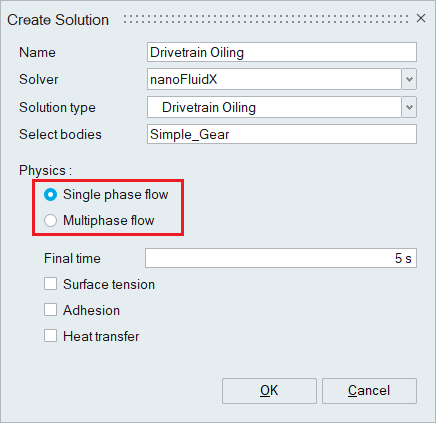

Physics can be solved based on single-phase and multiphase flow as follows:

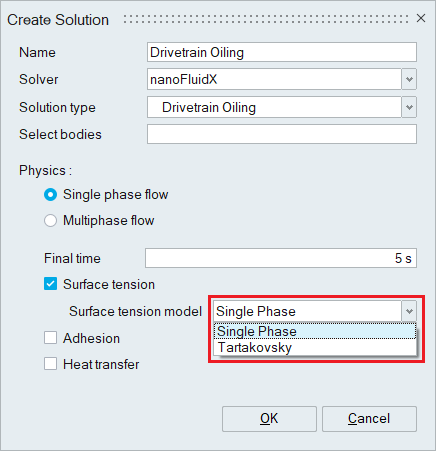

Surface tension

Choose if surface tension is active (surften_model) and which model to use. By default, surface tension is disabled, since it adds computational cost.

When creating a multiphase simulation, ADAMI should be chosen. This uses a physical value of surface tension coefficient (surf_ten) which can be calculated. Please refer to the nanoFluidX documentation for help with this value.

For singlephase simulations, SINGLE_PHASE or TARTAKOVSKY should be chosen. The Tartakovsky model has the advantage that a physical value of surface tension coefficient (surf_ten) can be calculated and used.

Surface Tension requires reference curvature (ref_curv) to be set in Domain parameters, along with surface tension coefficient (surf_ten) in Material (phase) parameters.

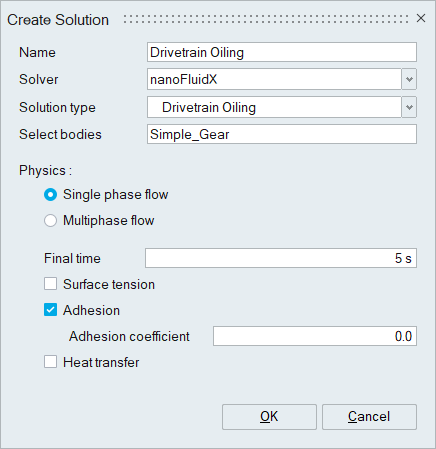

Adhesion

Specifies whether the Akinci wall adhesion model (adhesion_model) is active. This is used in conjunction with surface tension to define how the fluid interacts with the wall and the contact angle of a fluid droplet on the wall.

Heat transfer

Activates energy_transport so that the energy equation is solved by nanoFluidX for conduction and convection heat transfer.

When Heat transfer is used, initial temperature (temp_0), evolve temperature flag (evolve_temp), specific heat capacity of the material (heat_cap) and heat conduction coefficient of the material (heat_cond) should be set in Material (phase) parameters. Heat transfer and Flux output should also be requested in Results Request.

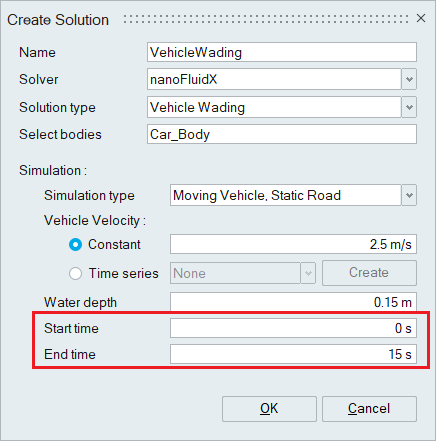

Simulation Start/End Time

This sets the duration of the simulation. Start time (t_begin) is 0 by default, this only needs to be adjusted when running a restart simulation. End time (t_end) defines the finishing time of the simulation.

Important: For Vehicle wading, currently there is no check to ensure that the vehicle will reach the end of the channel when using the Moving Vehicle approach. Please ensure that the time is sufficient for the channel and vehicle speed.

Vehicle Wading Simulation

There are two different simulation setups available:

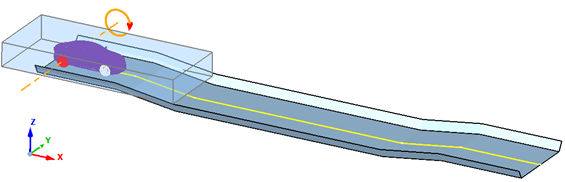

Moving Vehicle [Moving Vehicle, Static Road]

This approach mimics a real-world condition. A water channel is defined, and the vehicle drives through it. This approach is more realistic and captures the dynamic fluid behaviour during water entry and exit. It is more suitable for comparing to physical tests. However, it is the more computationally expensive approach.

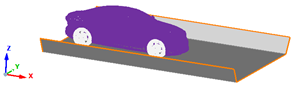

Static Vehicle [Static Vehicle, Moving Road]

This approach is simpler and uses a configuration like a wind tunnel. The vehicle remains static, but the road and wheels are assigned boundary conditions that mimic the correct vehicle speed. Water approaches the vehicle from an inlet at the front of the channel. This approach is less computationally expensive than the moving vehicle simulation, but it is not possible to capture the fluid behaviour during water entry and exit.

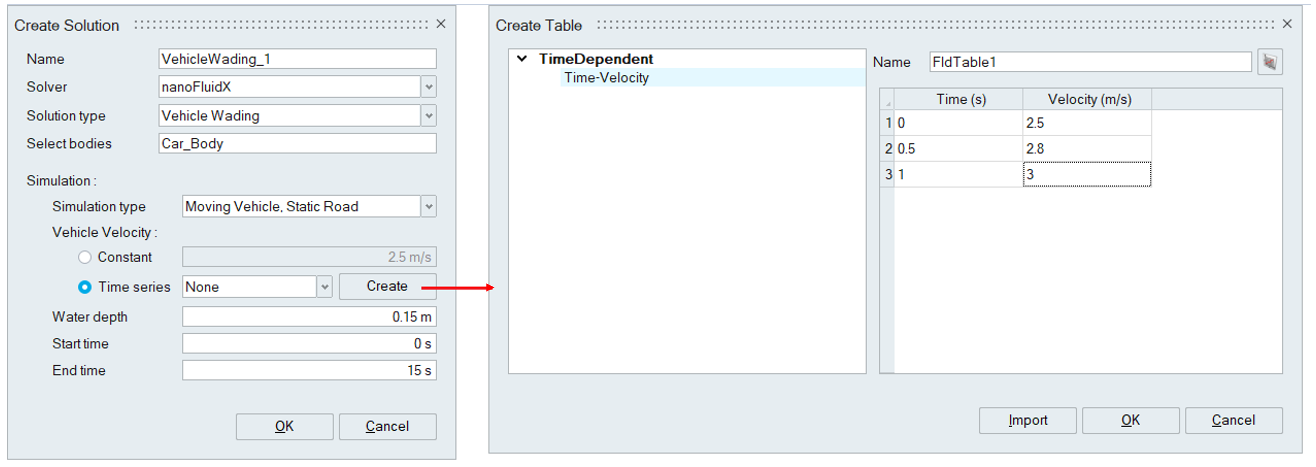

Vehicle Velocity

- Constant Velocity.

- Time series – Varying velocity over time.

Channel Definition and Vehicle Position

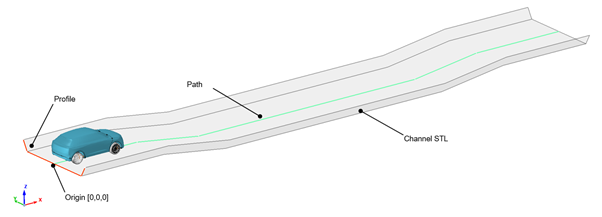

The channel is composed of three parts - the profile (cross section), path and STL. The solver uses the path and profile definition, while the channel STL is used for visualisation. The Channel is always created in the correct orientation, with the origin at 0,0,0. The vehicle must be aligned with the channel using the Transform tool.

Important: The initial position of the vehicle must not cross multiple segments of the channel in a moving vehicle type simulation.

Part Identification and Material Assignment

The materials (phase) types required for the vehicle wading simulation are created automatically when a Wading Solution is created. Using the Identify Parts menu to classify the bodies as wheels or car body, the materials are assigned automatically, and motions are created for the wheels.

Limitation: SimLab does not support identifying the orientation of the front and rear wheel pair of the vehicle. Please assign the correct material manually for wheels.

Domain

Definition of the computation domain is important. The domain must extend far enough upstream and downstream of the vehicle to capture the bow wave formed, along with the wake trailing the vehicle. The Domain can be updated automatically using the thunderbolt icon of Domain.

Auto vehicle Position

The thunderbolt icon in the Identify Part feature will automatically position the vehicle to the 1st segment of the channel. In addition, the domain will be created or updated automatically.