SS-T: 4135 Seam Weld Fatigue Analysis

Define and run seam weld fatigue analysis.

- Purpose

- SimSolid performs meshless structural

analysis that works on full featured parts and assemblies, is tolerant of

geometric imperfections, and runs in seconds to minutes. In this tutorial,

you will do the following:

- Perform seam weld fatigue analysis.

- Plot damage/life contour on seam welds.

- Plot damage/life along the weld length.

- Model Description

- The following file is needed for this tutorial:

- SeamWeldFatigue.ssp

Open Project

- Start a new SimSolid session.

-

On the main window toolbar, click Open Project

.

.

- In the Open project file dialog, choose SeamWeldFatigue.ssp

- Click OK.

Review Model

- In the Project Tree, expand the Structural 1 Analysis Workbench.

- Expand the Connections branch and review connections.

- Expand the Loads&Constraints branch and review the loads.

-

Click

(Results plot) and choose the desired plot to

review regions of high stress.

(Results plot) and choose the desired plot to

review regions of high stress.

Figure 2.

Add Fatigue Material Properties

If an SN curve has already been assigned, skip this step. Check the assigned material properties by right-clicking Assembly in the Project Tree and selecting .

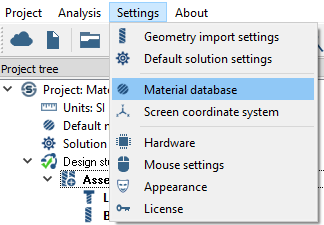

-

In the main menu, click .

Figure 3.

- In the Generic Materials group, right-click Steel and select Copy from the context menu.

-

Edit the copied material.

- Select Steel1 - Copy_0.

- Click Edit material.

-

Add fatigue curves.

- In the editing field of the dialog, expand the Fatigue properties branch and click Add stress-life (SN) curve....

- Verify the Curve definition method is set to Estimate from UTS.

- Click Add seam weld membrane stress-life (SN) curve....

- Verify the Curve definition is set to Estimate from UTS.

- Click Add seam weld bending stress-life (SN) curve....

- Verify the Curve definition is set to Estimate from UTS.

- Click Apply.

- Click Save.

Create SN Time Analysis

-

On the main window toolbar, click

(Fatigue analysis).

(Fatigue analysis).

-

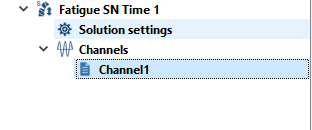

In the drop-down menu, select SN Time.

The new analysis appears in the Project Tree. The SN Time Workbench items are listed.

Import Channels

-

On the workbench toolbar, click

(Import channels).

(Import channels).

- In the file explorer, choose Channel1.csv.

-

Click Open.

The imported channel appears in the Project Tree.

Figure 4.

-

To review the imported channel, double click on

Channel1 in the Project Tree

or right-click and select Edit from the context menu.

Figure 5.

Create Events

-

On the workbench toolbar, click

(Create event).

(Create event).

- In the Event setup window, verify that Channel group is set to Channel1.

-

Create a channel-loadcase map.

-

Click OK.

The events appear in the Project Tree.

Edit Fatigue Solution Settings

For information about difference procedures supported for each setting, go to Apply Local Fatigue Solution Settings.

-

In the Project Tree, right-click on Solution

Settings and select Edit from the

context menu.

You can also double-click on Solution settings.

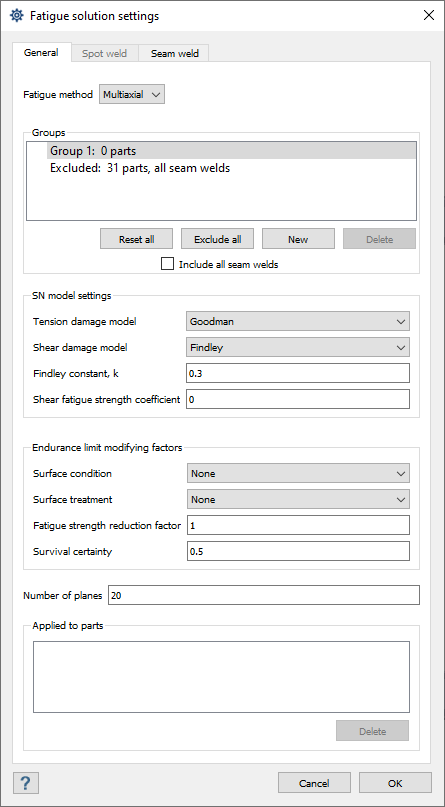

- In the Fatigue solution settings dialog, select the General tab.

- For Fatigue method, select Multiaxial.

-

For Groups, exclude all parts.

- Select Exclude all to remove all parts from damage evaluation.

- Ensure the Include all seam welds check box is not selected.

Figure 7.

- Select the Seam weld tab.

-

For Groups, accept the default Group 1.

No parts are excluded.

-

For Seam weld model

settings, set the following:

- Model method to Volvo.

- Stress combination to Normal.

- Mean stress correction to FKM.

- Mean stress sensitivity to 0.15.

- Thickness correction to Apply.

- Reference thickness for thickness correction to 25 mm.

- Reference exponent for thickness correction to 0.2.

- Set survival certainty to 0.5.

- Click OK.

Run Analysis

- On the Project Tree, open the Analysis Workbench.

-

Click

(Solve).

(Solve).

Figure 8.

Review Seam Weld Fatigue Results

- On the Analysis Workbench, select .

- In the dialog, for Result, select Damage.

-

For Events, choose one of the following.

- Select Total to view cumulative damage.

- Select an individual event of interest.

Max damage for each weld is shown under Seam welds. You can select the Max damage table header to sort the column in descending order. - Select a weld to review the damage contour plot for the weld.

- Use the Display point size slider bar to change the display size of points along the weld.

-

Click Plot to view a plot of damage along the weld

length.

Figure 9.

Figure 10.