Flow with Particles

![]()

Introduction

Flow with Particles Solution is used for modelling particle-fluid multiphase flow applications which are faced in productions including agriculture, mining, harvesting and pharmaceutical.

Workflow in SimLab

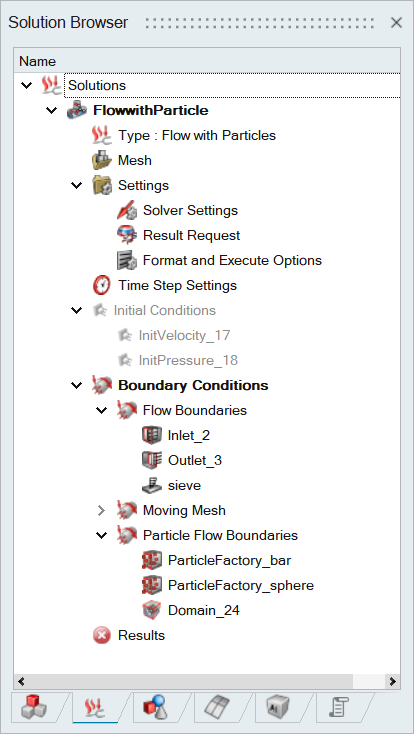

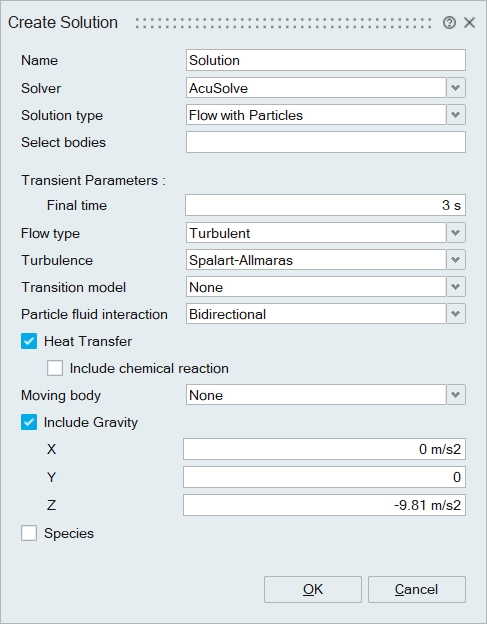

- Create Flow with Particles Solution by using Solution > Flow > Flow with Particles.

- Specify the time step for Flow and Particle Solvers.

- Specify the Particle fluid interaction type.

- Specify the details required for flow transient.

Step 2: Create Materials.

There are two ways to specify the materials for Particles and Geometry used in the solution.

Method 1: Include EDEM materials.

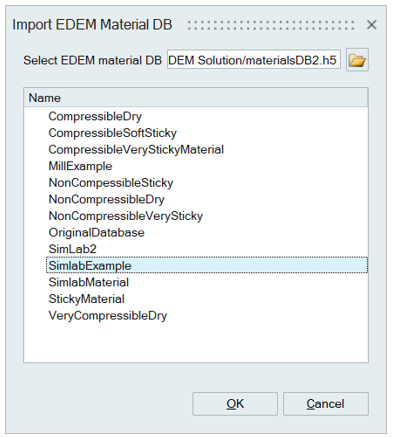

- EDEM material h5 file, is the edem material database which contains materials and interaction details of the particles.

- We need to include this h5 file which we can create it in the edem interface.

- Material Browser | Right click on Materials | Import EDEM Material DB will open the panel to select the material from material database.

- This selected material can be used as bulk material in Particle Inlet

definition.

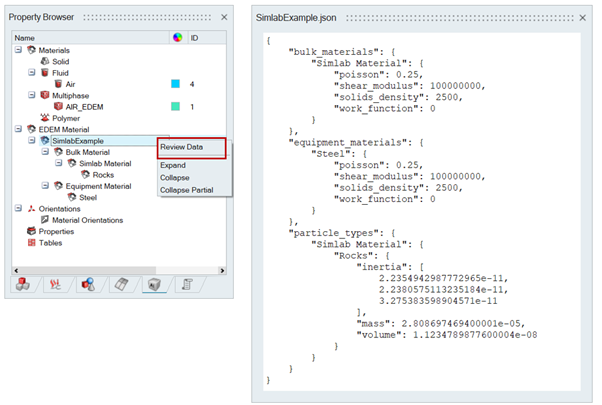

- User can review the selected material by right-clicking on it and choosing

the option “Review Data”. This will display the essential particle

properties.

Method 2: Create materials in Simlab

Method 2: Create materials in Simlab- Create Solid | Metal | Isotropic Material for shell bodies using Analysis | Materials.

- Create Bulk Material for Particles using Analysis

| Materials.

- Include particles to Bulk Material using Analysis | Material | Define Particles.

- Define interaction parameters for valid combinations of materials using Analysis | Material | Interactions.

- Method 1: User can create the bodies for EDEM using Geometry | Body | From Faces tool (This tool will automatically add the shell bodies created to the particle flow solution). Then users can assign equipment materials to shell body using Material option in UI right click menu.

- Method 2: Assign Equipment materials tool used to select the faces of multiphase material body and assign equipment materials to the surfaces.

- Analysis | Boundary Condition | Particle Inlet: Define Particle Factory surface, inlet type, generation rate and velocity.

- Analysis | Boundary Condition | Volume Packing: Define Volume Packing, particle body and different bulk material and its percentage.

- Analysis | Particle BC | Domain: Define domain for the simulation, this helps to improve computational performance by focusing calculations only on regions where particle activity is occurring.

- Define time step for Flow and Particle Solvers.

- Define the boundary condition for fluid, Initial condition, inlet outlet, moving mesh definitions.

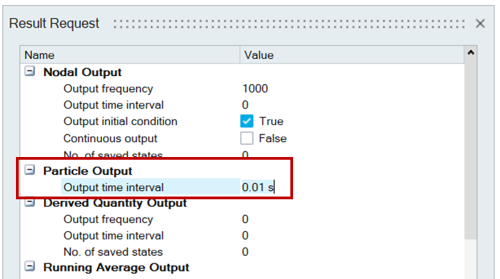

- Define Output time interval for Particle Output.

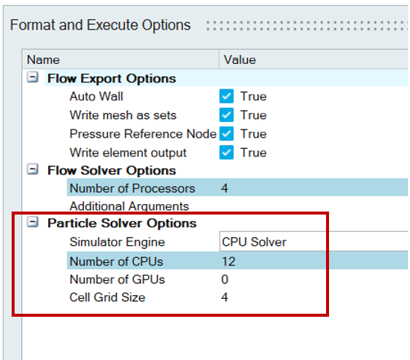

- Define Particle Solver Options.

- Click on Results | Update, exports the geometry details in obj files and write the json file which containing the Particle factory and moving mesh details. These are the input for EDEM solver.

- It solves this solution in AcuSolve, this result coupled with EDEM solver in the background.

Step 9: Results Display

- Following options are available:

- Display Flow Results

- Display Coupled Results

- Display EDEM Results

-

View in EDEM – Used to open the particle results in EDEM Interface for advanced post processing.

Stop after the current time step – Ends the simulation after completing the current time step and saves both EDEM and Flow results.

Include chemical reaction – Flag used to create chemical reaction for blast furnace applications.