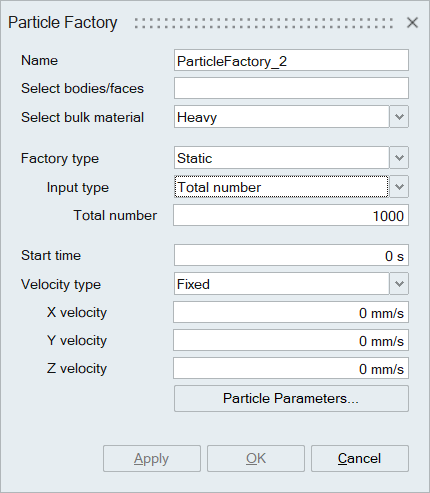

Particle Factory

![]()

The Particle Factory panel is used to specify the inflow boundary condition for Particle flow simulations.

Select faces/bodies:

- The select faces / bodies is used to select the faces/face groups/bodies that should be specified with inflow boundary.

Select faces:

- The select faces option is used to select the faces/face groups of volume meshed bodies that should be specified with inflow boundary condition.

Select bulk material:

- This option used to select bulk materials from the imported edem h5 file.

- To import the edem h5 material, go to Material browser | Materials | right click, select Import EDEM Material DB option, and select the h5 file, which user can create in EDEM interface.

Factory type: User can specify Static and Dynamic particle factories

Input type:

- The option used to control the number of particles generated either total number or unlimited.

- Total number - Specify the total number of particles to be created at the inlet.

- Unlimited number - By default it considers 1 million particles.

- Fill section – Added for static factories.

- Total mass – Specify the total mass of the particles.

Generation rate:

- Target number - Specify the total number of particles to be generated per second at the particle inlet.

- Target mass - Specify the target mass of the particles to be generated per second.

Start time:

This option used to specify the start time for particle creation.

Velocity type:

Particles can be given a velocity at the time of creation. Options are:

| Velocity Type | Input Details |

|---|---|

| Fixed | Velocity component values in the X, Y and Z |

| Linear distribution | The particles are given velocities that fall on the line segment between the two velocity vectors provided by user. Start and End velocity. |

| Normal distribution | The particle direction, mean velocity and the standard deviation must be defined. |

| Random | Each particle is given a velocity at random within a defined range of minimum and maximum. |

| Spray | The particles are formed in a conical spray. The spray direction is defined as a velocity vector. The angle is the angle of maximum deviation from the normal. The mean velocity and standard deviation must also be defined. |

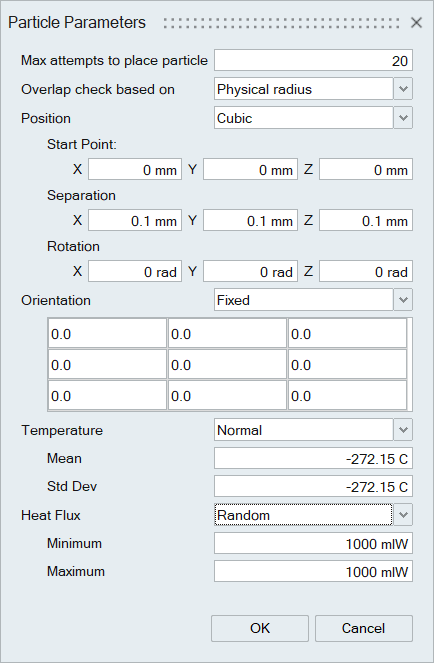

Particle Parameters :

- Max attempts to place particles – Particle created at the inlet can never be placed one on top of another. This parameter set the max. number of attempts to find free space to place a particle.

- Overlap check based on – Check if there is any overlapping of particles created at the inlet based on the radius of the particles.

Particle Parameters Table :

| Particle Parameters | Description | Type | Data and Unit |

|---|---|---|---|

| Position | Specifies the arrangement of the particles | Random | - |

| Cubic | Start point, Separation, Rotation | ||

| Body-Centered Cubic (BCC) | Start point, Separation, Rotation | ||

| Face-Centered Cubic (FCC) | Start point, Separation, Rotation | ||

| Orientation | Particle can be oriented in a specified way at the time of creation | Random | |

| Fixed | Orientation Matrix | ||

| Temperature | Specifies the temperature of the Particle | Fixed | Value in K |

| Normal | Mean and Std Dev in K | ||

| Random | Min and Max value in K | ||

| Heat Flux | Specifies the heat flux of the Particle | Fixed | Value in W |

| Normal | Mean and Std Dev in W | ||

| Random | Min and Max value in W |