Permas Contact Parameters

Following method of contact can be defined.

- Surface To Surface Node

- Surface To Surface

- Node To Node

- Surface To Node

- Node To Surface

Note: This option Face/Node-To-Node is used to specify element

face based contact or node based contact. Another set of option Surface-To-Node

(or) Node-To-Surface is used to specify the contact formulation.

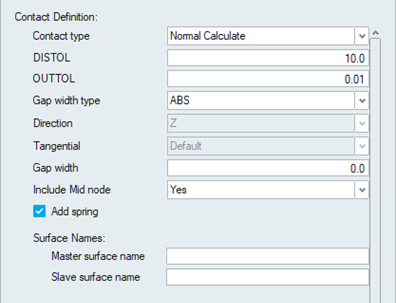

- Contact Type: Used to defined the contact method - Normal Calculate / Normal Fixed / MPC Coupling / Force Lock. In Normal Calculate type, the normal will not be specified and it will be calculated while solving. In Normal Fixed type, the Normal = Fixed and Friction = Fixed will be set. When MPC Coupling option is chosen, Multi Point Constraint will be defined between the contact pairs. Degree of Freedom can be specified if MPC coupling is defined.

- DISTOL: Used to define Distance search tolerance.

- OUTTOL: Used to define Out of boundary search tolerance.

- Gap Width Type: User can select, whether to include(ADD) or ignore(ABS) the geometrical gap between the contact faces.

- Gap Width: Used to define Gap width between contact pairs.

- Direction: This option is enabled when Node-To-Node contact type is selected. Used to define the degree of freedom for node based contacts.

- Tangential: This option is enabled when Node-To-Node contact type is selected. Used to define the tangential direction for node based contacts.

- Include Mid node: The option is used to specify if the mid nodes in

the master and slave are to be used in contact surface creation.This option

will not have any effect on linear elements. This option takes the following

values.

- Yes: The global setting of the solver will be used. By default the mid nodes of master and slave will be used in contact surface creation.

- No: Mid nodes of master and slave will not be used in contact surface creation.

- Connect to corner nodes using MPC: Mid nodes of master and slave will not be used in contact surface creation, but these mid nodes will be tied to the corner node.

Note: Using "No" option may cause error in solving, hence additional MPC might be needed to constrain the model. - Add Spring: Some times it is necessary to apply a

soft spring to prevent rigid body motion between contact surfaces. SimLab

automatically adds a spring between master and slave surfaces in (x,y,z)

direction if this option is used.

- Type: User can define the type of spring to be created.

- General

- Iso

- Number of spring:This option is used to create the user defined number of springs between the main and secondary surfaces. Springs will be created at the outer most edges of the contact surfaces.

- DOF: User can define the DOF for the spring to be created.

- Type: User can define the type of spring to be created.