Abaqus Contact Parameters

Following method of contact can be defined.

- Face-Face

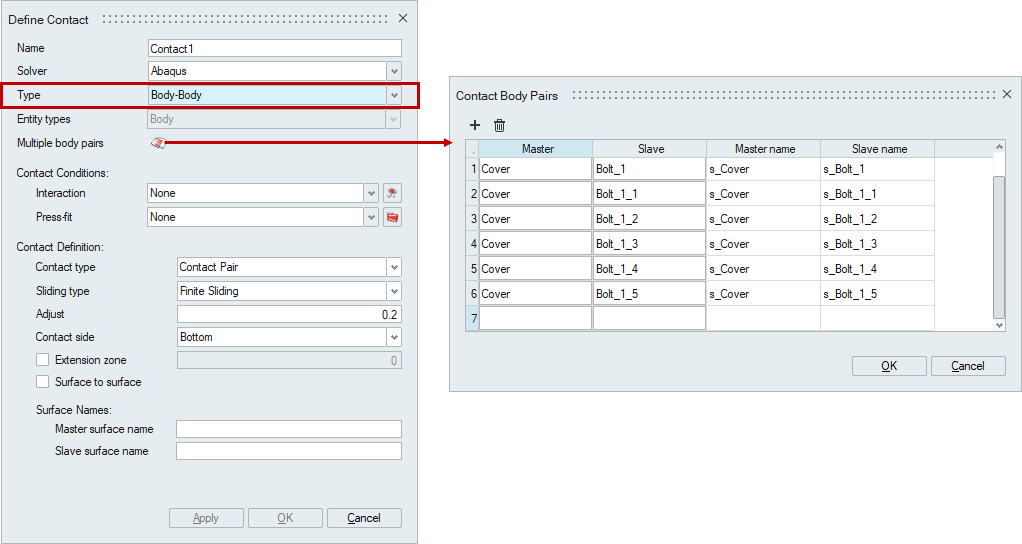

- Body-Body

- Edge-Edge

- General

- Self contact

- Face-Edge

- Contact Type: Used to define Contact Pair / Contact Tied / Tie.

- Sliding Type: Used to set Small Sliding contact method. If None or Finite sliding is selected, then Abaqus will use Finite Sliding contact method.

- Adjust: Used to specify a value to adjust the initial positions of the contact surfaces.

- Extension Zone: Used to specify a value by which the master surface is extended during analysis. The value must lie between 0.0 and 0.2.

- Contact Side: Used to define the surface identifier in case of contact between shell elements. SPOS will be written out when Top is selected whereas SNEG written out when Bottom is selected. When None is specified, neither SPOS/SNEG will be written out, Abaqus will determine the surface identifier.

- Surface-To-Surface: Used to set Surface-To-Surface method rather than the default Node-To-Surface method. Usually Surface-To-Surface is preferred for higher stress accuracy in the contact calculations.

- Circumferential Surface Smoothing: Used to define geometric correction for circumferential surfaces.

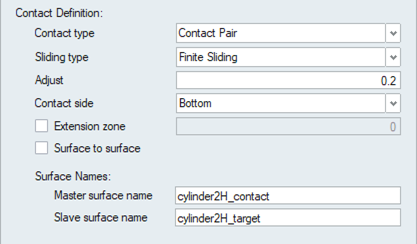

- Surface Names: Used to define names for the master and slave surfaces involved in the contact definition. If the surface names are not defined, SimLab will assign names based on the body names of the surfaces, like Master surface name will be <Master_Body_Name>_<Slave_Body_Name> and Slave surface name will be <Slave_Body_Name>_<Master_Body_Name>.

- Position Tolerance: Parameter for Tie contact that is used to tie all the nodes lying within Position Tolerance.

- Tied Slave Node Set: Used to tie nodes present in the node set.

- Multiple body pairs: This option allows to select

multiple body pairs to define contact.