Length

This rule checks for a trace length violation.

- Item: Input item name.

- Test Item: Define test item.

- Net Length Check: Checks the total length of specified net. You also

can check the length of the specified net between start component

and end component.

Figure 1. - Pin-to-Pin Length Check: Checks the pin to pin length of specified

net.

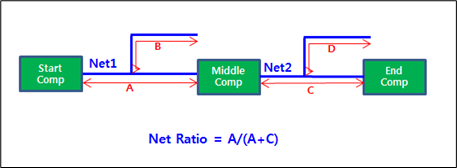

Figure 2. - Net Ratio Check (Net1/(Net1+Net2)): Checks the ratio of net1 with

net2.

Figure 3. - Branch Ratio Check (Branch1/(Branch1+Branch2): Checks the ratio of

branchlength1 with branch length2.

Figure 4.

- Net Length Check: Checks the total length of specified net. You also

can check the length of the specified net between start component

and end component.

- Net1: Select a target net group.

- Start Component/End Component: A test is performed between the start component and the end component.

- Component Keep IN/OUT: Define the test region. For example, you can test

inside or outside the breakout region of CPU with different test

values.

- Component Group: Select the required component group which is used for defining the test region.

- Region: Define the required test region.

- IN: Test inside of the breakout region of target component.

- OUT: Test outside of the breakout region of target component.

- Range (COC+distance): Enter the distance value to define breakout range. The COC (Component Overlap Check) plus this distance value is considered the test range.

Net Length Check

- Check Length L: Assign a reference length.

- Tolerance (%): Define allowable tolerance ratio of length difference compared to the reference length.

- Check Type: Select a length check criteria type between Min, Max and Range.

- Max: Total length should be less than Check Length L + Tolerance.

- Min: Total length should be longer than Check Length L – Tolerance.

- Range: Total length should be between Check Length L – Tolerance and Check Length L + Tolerance.

- Manhattan Ratio Check: Check length ratio between routing length and

manhattans length.

- Allowable Ratio (%): Assign the required ratio. If total routing length of net is Between Manhattan Length * (1-Ratio/100) and Manhattan Length *(1+Ratio/100), it reports as passed.

- Middle Component

- Component: Specify the middle component.

- Exclude Component: Specify the component should be excluded.

- Net2: Specify middle net.

- Options

- Include VIA Length: The length of via will be added to the total trace length value.

- Copper Length Compensation: If copper is included in trace, choose a

copper Polygon length measuring method between Exclude, Manhattan

Distance, and Minimum Distance.

Exclude: Ignore copper length.

Manhattan Distance: Use Manhattan distance for copper length value.

Min Distance: Use minimum distance for copper length.

Figure 5.

Pin-to-Pin Length Check

- Check Length L: Assign a reference length.

- Tolerance (%): Define allowable tolerance ratio of length difference compared to the reference length.

- Check Type: Select a length check criteria type between Min, Max and Range.

- Max: Total length should be less than Check Length L + Tolerance.

- Min: Total length should be longer than Check Length L – Tolerance.

- Range: Total length should be between Check Length L – Tolerance and Check Length L + Tolerance.

- Manhattan Ratio Check: Check length ratio between routing length and

manhattans length.

- Allowable Ratio (%): Assign the required ratio. If total routing length of net is Between Manhattan Length * (1-Ratio/100) and Manhattan Length *(1+Ratio/100), it reports as passed.

- Start Pin: Specify start pin of net.

- Click required component group from Component Group List.

- Click the arrow. All components that belong to that group are listed.

- Assign required pin number into Select Pins column.

- Select required pins and click OK to close this dialog.

-

End Pin: Specify start pin of net.

- Click the required component group from the Component Group List.

- Click the arrow. All of the components that belong to that group are listed.

- Assign required pin number in the Select Pins column.

- Select required pins and click OK to close this dialog.

- Options

- Include VIA Length: The length of via is added to total trace length value.

- Copper Length Compensation: If copper is included in trace, choose a copper polygon length measuring method between Exclude, Manhattan Distance and Minimum Distance.

- Exclude: Ignore copper length.

- Manhattan Distance: Use Manhattan distance for copper length value.

- Min Distance: Use minimum distance for copper length.

Figure 6.

Net Ratio Check

- Net Ratio Check (Ratio = Net1/(Net1+Net2))

- Check Ratio: Assign the required ratio.

- Check Type: Select a net ratio check criteria type between Min and Max.

- Middle Component:

- Component: Specify middle component.

- Exclude Component: Specify the component that should be excluded.

- Net2: Specify middle net.

- Options

- Include VIA Length: The length of via will be added to the total trace length value.

- Copper Length Compensation: If copper is included in trace, choose a copper polygon length measuring method between Exclude, Manhattan Distance, and Minimum Distance.

- Exclude: Ignore copper length.

- Manhattan Distance: Use Manhattan distance for copper length value.

- Min Distance: Use minimum distance for copper length.

Figure 7.

Branch Ratio Check

- Branch Ratio Check (Ratio = Branch1/(Branch1+Branch2))

- Check Ratio: Assign the required ratio.

- Check Type: Select a net ratio check criteria type between Min and Max.

- Middle Component:

- Component: Specify middle component.

- Exclude Component: Specify the component that should be excluded.

- Options

- Branch2 measure base: If passive components exist in net, you can

assign branch2 measure reference.

- From first passive component to middle component: The branch

length2 is measured from first passive component to middle

component.

Figure 8. - From last passive component to middle component: The branch

length2 is measured from last passive component to middle

component.

Figure 9.

- From first passive component to middle component: The branch

length2 is measured from first passive component to middle

component.

- Copper Length Compensation: If copper is included in trace, choose a

copper polygon length measuring method between Exclude, Manhattan

Distance and Minimum Distance.

- Exclude: Ignore copper length.

- Manhattan Distance: Use Manhattan distance for copper length value.

- Min Distance: Use minimum distance for copper length.

Figure 10.

- Branch2 measure base: If passive components exist in net, you can

assign branch2 measure reference.