Electric Power Assisted Steering System

A power assisted steering system that helps driver steer the vehicle by adding controlled energy to the steering system, making it easier for drivers to perform a turn or a maneuver.

- A Hydraulic Power Assisted Steering System (HPAS) which uses a pump providing pressure in a fluid through a hydraulic system connected with cylinders to the rack-pinion assembly, reducing driver’s effort.

- An Electric Power Assisted Steering System (EPAS) which uses a DC electric motor providing a controlled assist torque to the steering system.

Electric Power Assisted Steering Systems have become more popular during the years for several reasons. Firstly, an EPAS system can be easily “tailored” to its individual needs by having different behavior for different vehicle velocities. Most EPAS systems in the market tend to provide higher assist when vehicle is moving at slow speed and reducing it for faster vehicle’s speed. Also, unlike a HPAS that continuously drives a hydraulic pump to maintain system pressure, the efficiency advantage of an EPAS system is that it powers the EPAS motor only when necessary. This results in reduced vehicle fuel consumption compared to the same vehicle with an HPAS. Finally, an EPAS system consists of less parts and needs less maintenance making it more appealing as a power assisted steering system.

There are four forms of EPAS systems based on the position of the assist motor. They are the column assist type (C-EPS), the pinion assist type (P-EPS), the direct drive type (D-EPS) and the rack assist type (R-EPS). The C-EPS type has a power assist unit, torque sensor, and controller all connected to the steering column. In the P-EPS system, the power assist unit is connected to the steering gear's pinion shaft. This type of system works well in small cars. The D-EPS system has low inertia and friction because the steering gear and assist unit are a single unit. The R-EPS type has the assist unit connected to the steering gear. R-EPS systems can be used on mid- to full-sized vehicles due to their relatively low inertia from high reduction gear ratios.

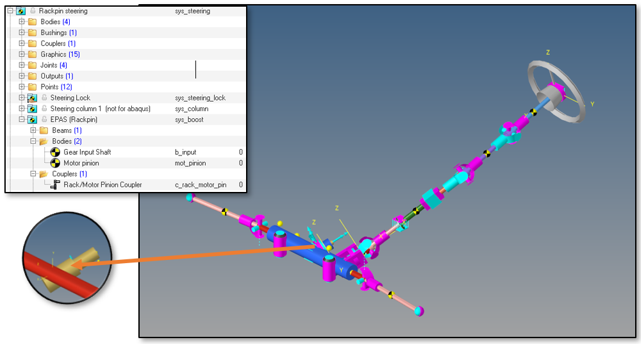

An Electric Power Assisted Steering System of a double pinion configuration is available in the Assembly Wizard plug-in for a Rack-pin style steering system in the Car/Small truck library and a Pitman steering system in the Heavy Truck library.

Working with MotionView/MotionSolve Models

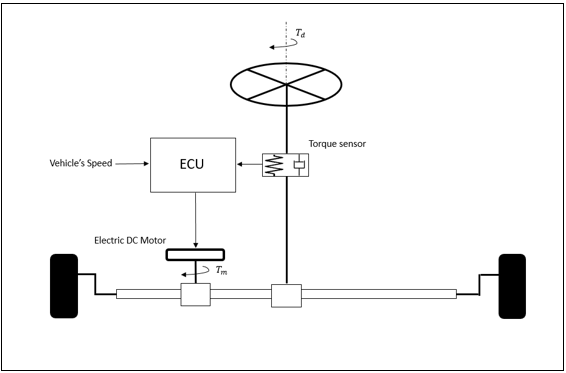

The EPAS electronic control unit calculates the desired assist torque as a function of driver’s torque, measured by a torque sensor placed on steering column, and vehicle’s speed.

- Electric Motor

- Electronic Control Unit

- Torque Sensor

Electric Motor

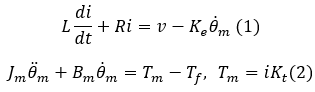

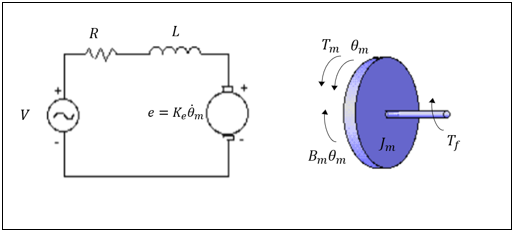

A simple electric DC motor is governed by two main dynamic equations:

where  and

and  are inertial and damping constants of the motor,

are inertial and damping constants of the motor,  and

and  are inductance and resistance of motor armature winding,

are inductance and resistance of motor armature winding,  is the armature current,

is the armature current,  and

and  are t he back EMF and torque constants of the motor,

are t he back EMF and torque constants of the motor,  and

and  are the electromagnetic torque created by the motor and the counter balance torque acting

on motor shaft due to tire forces.

are the electromagnetic torque created by the motor and the counter balance torque acting

on motor shaft due to tire forces.

on pinion due to tires lateral force.

on pinion due to tires lateral force.

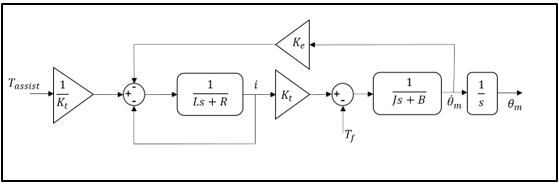

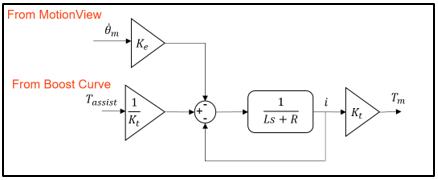

- The Twin Activate motor part uses motor’s angular velocity to

calculate the back EMF voltage while with current value feedback the desired electrical

torque is exported.

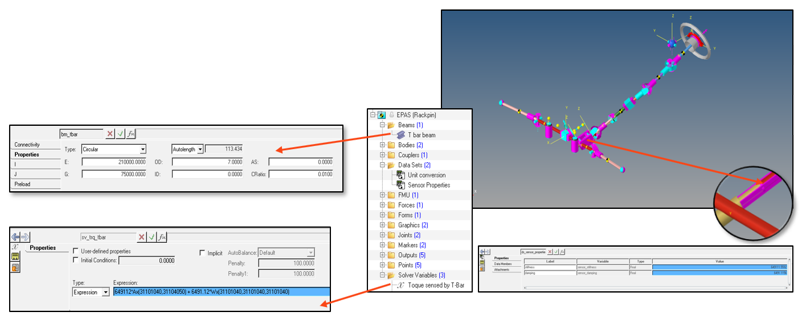

Figure 4.

- The MotionView motor part contains a body to represent

motor’s inertial properties and a rack and pinion coupler with the rack body to interact

with the system.

Figure 5.

| Parameter | Model | Default Value | Unit |

|---|---|---|---|

Inductance ( ) ) |

Twin Activate | 9.06e-5 |  |

Resistance ( ) ) |

Twin Activate | 0.0035 |  |

Torque Coef. ( ) ) |

Twin Activate | 0.05285 | - |

Back EMF Coef. ( ) ) |

Twin Activate | 0.05285 | - |

Inertia ( ) ) |

MotionView | 1000 |  |

The MotionView diagram and the FMU used in MotionView model can be accessed from this location within the installation: <install_dir>\hwdesktop\hw\mdl\mdllib\Common\FMU_Library\EPAS\FMU_source

Torque Sensor

| Parameter | Default Value | Unit |

|---|---|---|

| Young's Modulus (E) | 21000 |  |

| Shear Modulus (G) | 75000 |  |

| Outer Diameter (OD) | 7 |  |

| Inner Diameter (ID) | 0 |  |

| Damping Coef (CRatio) | 0.01 | - |

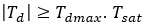

Boost Curve

, increasing linearly until value

, increasing linearly until value  which is reached when

which is reached when  value is also decreasing linearly with the vehicle’s longitudinal

velocity in order to maintain vehicle’s stability and controllability. Driver’s input torque

value is also decreasing linearly with the vehicle’s longitudinal

velocity in order to maintain vehicle’s stability and controllability. Driver’s input torque

and vehicle’s velocity

and vehicle’s velocity  are the plant output variables from vehicle’s model in MotionView.

are the plant output variables from vehicle’s model in MotionView.

| Parameter | Default Value | Unit |

|---|---|---|

Driver’s min torque ( ) ) |

1 |  |

Driver’s max torque ( ) ) |

8 |  |

Motor max torque ( ) ) |

20 |  |

Vehicle critical velocity ( ) ) |

100 |  |

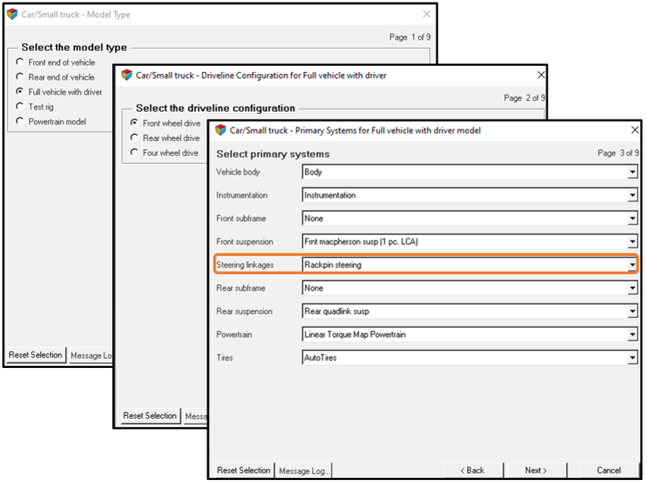

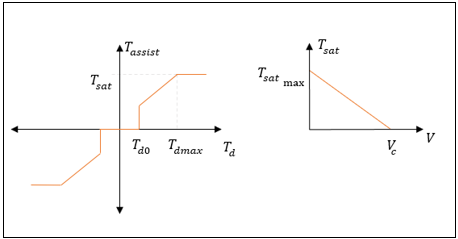

Create a Full Vehicle Model with EPAS System

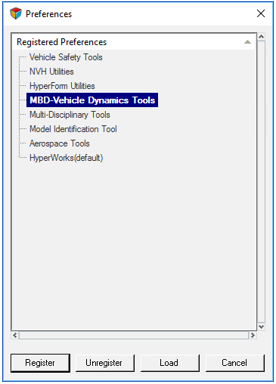

The MBD-Vehicle Dynamics Tools must be loaded as a preference file.

The Update Model utility is only available when the profile MBD-Vehicle Dynamics Tools is loaded. Follow the steps below to load this profile and access the utility:

-

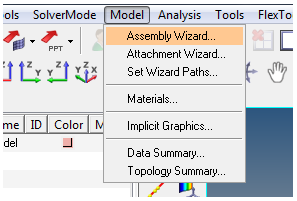

From the Menu bar, select .

Figure 8.

-

Choose the MBD-Vehicle Dynamics Tools profile and click

Load.

Figure 9.

-

Click .

Figure 10.

-

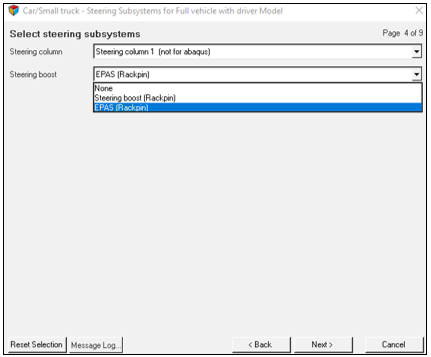

In the Model Type window, select the following:

-

In steering subsystems EPAS (Rackpin) will be available

as a Steering boost method.

Figure 12.

Other options for the model systems are left to your discretion.

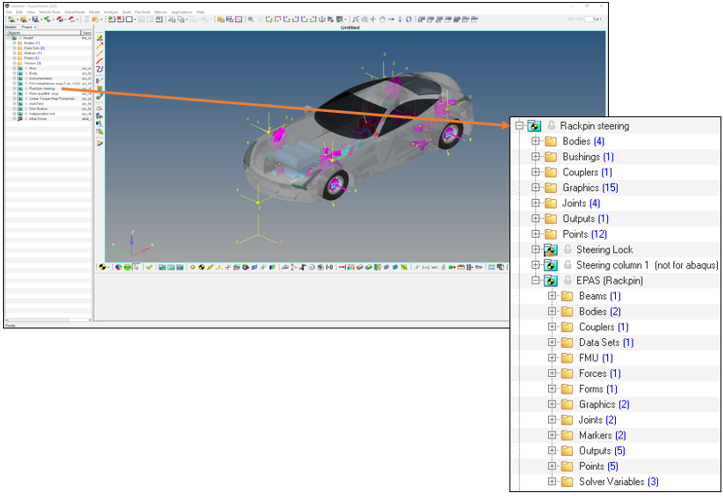

Completing the Assembly Wizard’s selections will lead to a full vehicle model with Altair Driver and an Electric Power Assisted Steering System.Figure 13.

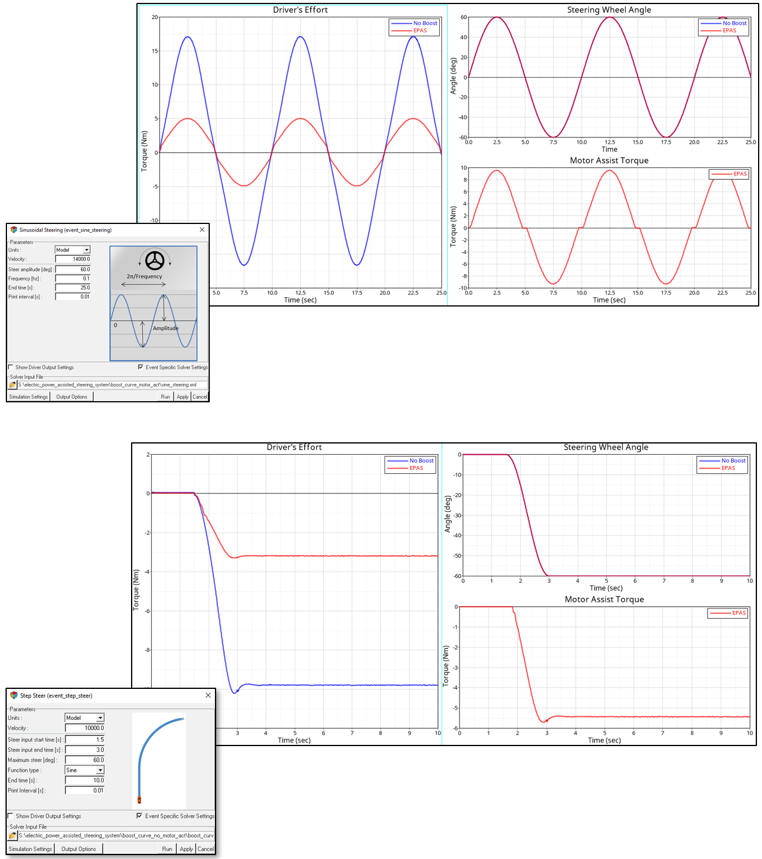

Steering maneuver simulation such as Sinusoidal Steering or Step Steer events can help you understand the behavior of an EPAS system. In the following diagrams these two events are presented for the displayed event settings and the results are compared with those of a vehicle with no steering boost system, performing the exact same maneuvers.

Figure 14.