WSeal Element

WSeal Element General Description and Quick Guide

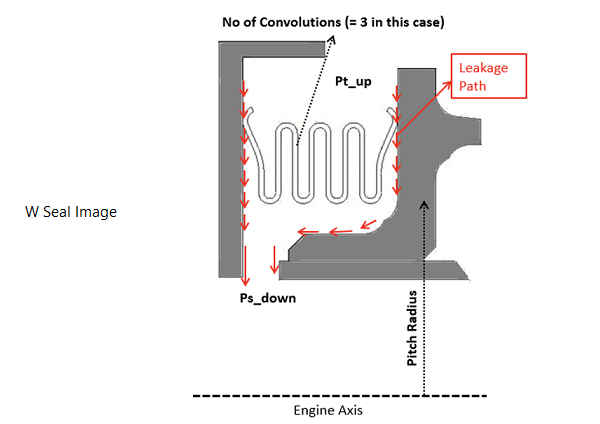

Flow Simulator WSeal element models the leakage flow across the W-Seal. This can be used only in Compressible (e.g. gas systems) analysis.

WSeal Element Inputs

Table of the inputs for the WSeal Element.

| Element Specific W Seal Input Variables | ||

|---|---|---|

| Index | UI Name (. flo label) | Description |

| 1 | No. of. Convolutions (NOC) | Number of Convolutions |

| 2 | Youngs Modulus | Youngs Modulus of WSeal Material |

| 3 | Pitch Radius | Pitch Radius measured from Engine centerline |

| 4 | Initial Compression | Initial Compression |

| 5 | Compression Model |

|

| 6 | Load (Deflection Based) | Load Acting on WSeal (Needed only when Compression model == ON) |

WSeal Element Theory Manual

| Nomenclature: | |

| : Mass flow rate | Specific heat Ratio |

| Tt: Total Temperature | R: Gas Constant |

| Pt: Total pressure | Ts: Static Temperature |

| Ps: Static pressure | Density |

| gc: Gravitational Constant | |

| Subscripts: | |

| in: Upstream station | ex: Downstream station |

W seal element solves the flow rate based on cross-sectional area and losses provided from user input.

If Compression if off, then

If Compression is on, then the calculated compression is based on number of convolutions

| Number of Convolutions | K_emp Calculations |

| 1 | |

| 2 | |

| 3 | |

| 4 |

![]()

![]()

Now the effective Clearance is computed by the following formula

![]()

![]()

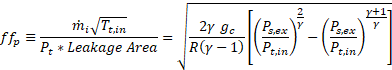

Mass flow rate is calculated by Flow Function equation,

For Choked Condition

![]()

WSeal Element Outputs

The following listing provides details about WSeal Element output variables.

| Element Specific W Seal Output Variables | |||

|---|---|---|---|

| Index | Field | Description | Units |

| 1 | No.of. Convolutions | Number of Convolutions (User Input) | Unitless |

| 2 | Youngs Modulus | Youngs Modulus of WSeal Material (User Input) | Psi, mPa |

| 3 | Pitch Radius | Pitch Radius measured from Engine centerline (User Input) | in, m |

| 4 | Initial Compression | Initial Compression (User Input) | in, mm |

| 5 | Compression Model |

(User Input) |

|

| 6 | Load (Deflection Based) | Load Acting on WSeal (Needed only when Compression model= ON) (User Input) | lbf, N |

| 7 | Flow Regime | If Chocked flow | |

| 8 | Calc Compression | Calculated Compression if Compression model = ON | in, mm |

| 9 | Total Compression | Initial Compression + Calc Compression | in, mm |

| 10 | Effective Clearance | Clearance computed | in, mm |

| 11 | Leakage Area | Leakage Area | in2 , m2 |

| 12 | Leakage Flow | Mass flow rate | Lbm/s, kg/s |

| 13 | VEX | Exit Velocity | ft/s, m/s |

| 14 | MACHEX (EXMN) | Exit Mach number | Unitless |

| 15 | PTS | Total Pressure Upstream | psi, mPa |

| 16 | PSEB | Static Pressure Downstream | psi, mPa |

| 17 | PTEX | Total Pressure Downstream | psi, mPa |

| 18 | TTS | Total Temperature Upstream | F, K |

| 19 | TTEX | Total Temperature Downstream | F, K |

| 20 | RHO | Density | lb/in3, kg/m3 |

| 21 | Gamma | Gamma | Unitless |

References

- Neelesh, S., Wolfe, C., Sezer, I., Ziegler, R., Chupp, R., “Chaterterization of metallic W-seals for inner to outer shroud sealing in industrial gas turbines”, Proc. ASME Turbo Expo 2012, GT2012-68131.

- Neelesh, S., “ Characterization of Metallic W Seals for Inner Shroud to Outer Shroud Sealing”, GRC-TISCAT report - 2010GRC861.

- Farahani, A., Childs, P., “Nozzle guide vane static strip seals”, Proc. ASME Turbo Expo 2006, GT2006-90185.

- Farahani A., Childs, P., “Characterization of static strip Seal flow”, Proc. ASME Turbo Expo 2007, GT2007-27469.

- Farahani, A., Childs, P., “Validation and comparison of strip seal design for gas turbine engine nozzle guide vanes”, Proc. 2008 ASME IMECE2008-68311.

- Ludwig, L., P., Johnson, R., L., “Sealing technology of aircraft gas turbine engines”, NASA Technical Memorandum -TM X-71607.

- “Seal Technology in Gas Turbine Engines”, AGARD Conference Proc – 237.

- Steinetz, M., Bruce, “Seal Technology”, Mechanical Engineers handbook – Materials and Mechanical design, Volume 1, Third Edition.

- Bill, C., Robert, “Wear of Seal Materials used in Aircraft Propulsion Systems”, Wear, 59 (1980) 168-189.

- http://www.nicholsons.com/pdf/E-Seals.pdf, Nicholsons Seals.

- http:/www.eaton.com/ecm , “Resilient Seals”, EATON’S Aerospace, TF100-35C_Resilient Seals.