Get Started

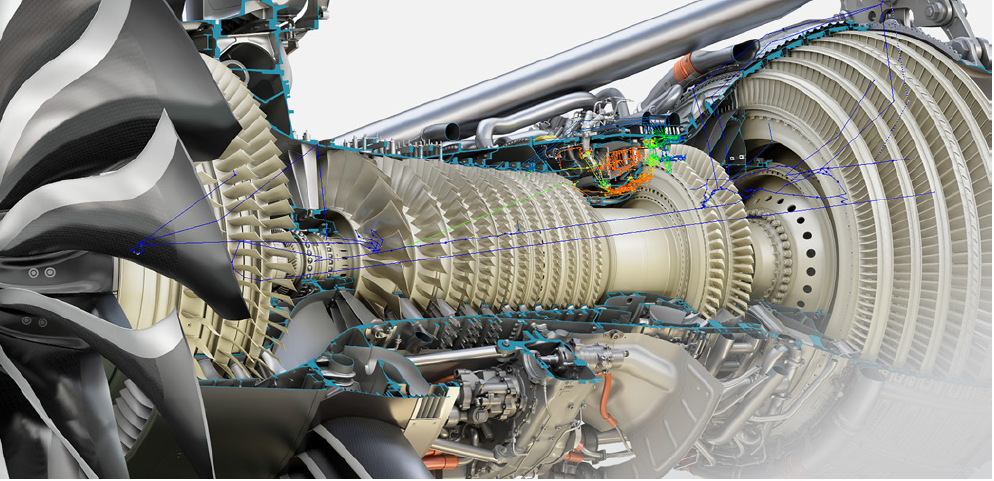

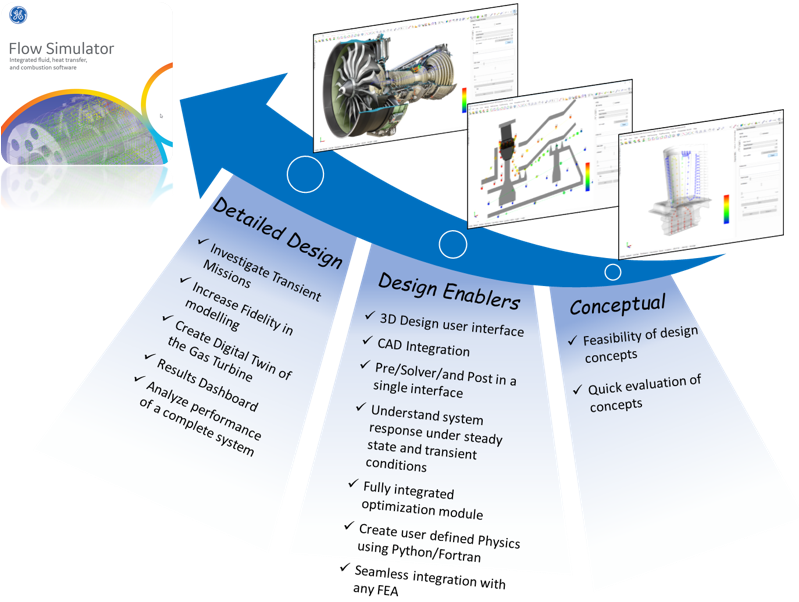

Flow Simulator is an integrated flow, heat transfer, and combustion design software that enables multidisciplinary engineering simulations to optimize machine design.

Benefits

Use Flow Simulator to study how systems behave in the real world, where fluid is the driving factor. System simulation relays the overall effect of changing specific properties on components, allowing clients to extensively examine all possible variations in the design and optimization of systems. Flow Simulator pushes the boundaries of design to drive better outcomes, guided by the principle that more informed decisions lead to superior products. Through advanced fluid simulations, you can instantly examine and predict future outcomes with complete confidence and optimal efficiency.

Features

- Intuitive Interface

- Flow Simulator has a modern Qt/Qt-web based single interface for pre, post, solve, and optimization. The three-dimensional design environment gives users the ability to overlay/integrate the network model with 3D CAD. The ability to incorporate and integrate your own IP and element formulations seamlessly utilizing Python scripting/Fortran program. An integration with Excel allows for automating the creation of the flow/thermal network models based on the design configurations.

- Flow Network Modeling

- An extended library of preconfigured elements and components leveraging a large set of publicly available experimental data for pressure drop and heat transfer characteristics.

- Thermal Network Modeling

- A resistor-capacitor based solver with lumped masses simulates conduction, convection, and radiation modes of heat transfer. This is fully coupled to the flow solver for steady state and transient conjugate heat transfer analysis capabilities.

- Control System Module

- Includes proportional integral derivative (PID) controllers, feed-forward, and mission that can be integrated with flow/heat transfer model to optimize the simulated-machine operation during cycle/mission analysis.

- Optimization Module

- Monte Carlo, Optimal Latin Hypercube, N-factorial analyses are provided to quickly explore the entire design space within a 3D modeling environment; an analytical model can be parametrized based on flow configuration, shape, dimension, and thermal characteristics to achieve an optimal cost-benefit design.

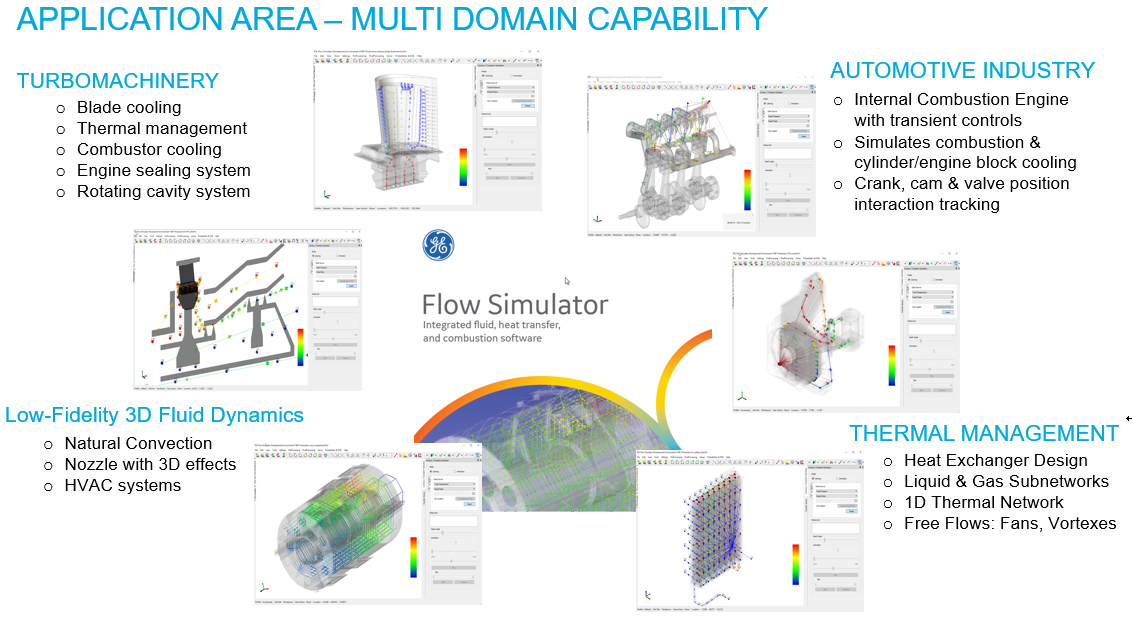

Industry Applications

- Turbomachinery

- Flow Simulator can be used to predict the turbomachinery aerothermal of engine sealing systems, structures cooling, rotating cavity systems, component cooling, combustor design and optimization, fuel/lube systems, and thermal management through the sever harsh working conditions of long transient flight missions.

- Automotive

- Flow Simulator can be used in the automotive industry for vehicle thermal management systems, fuel systems, exhaust systems and HVAC system modeling.

- Energy

- In the energy sector, it can be used to predict the turbomachinery aerothermal for secondary system cooling, component cooling, combustor design and optimization, fuel/lube systems, and power plant piping network and thermal management. The software can also be used for renewable wind turbines aerothermal design and optimization and electrical generator cooling and thermal management. Oil & gas industry engineers can use Flow Simulator for turbomachinery aero derivatives and centrifugal compressors secondary system cooling, component cooling, fuel/lube systems, and thermal management.