Battery Thermo Electric (OptiStruct)

![]()

- Electro-chemical behaviour of battery cells is modelled using the

Equivalent Circuit Model (ECM). Based on ECM parameters, the heat

generation in the jellyroll of each cell is computed.

- In jellyroll, the heat generation is from both Electro-chemical reaction and Joule heating.

- Joule heating which is the only source of heat generation in other electrical components is also included in the analysis.

- In electrical subcase, each jellyroll is represented as an 1D element (BCELL). ECM property is assigned to this element.

- In thermal subcase, the heat generated from 1D element is mapped to the 3D mesh of the jellyro.l

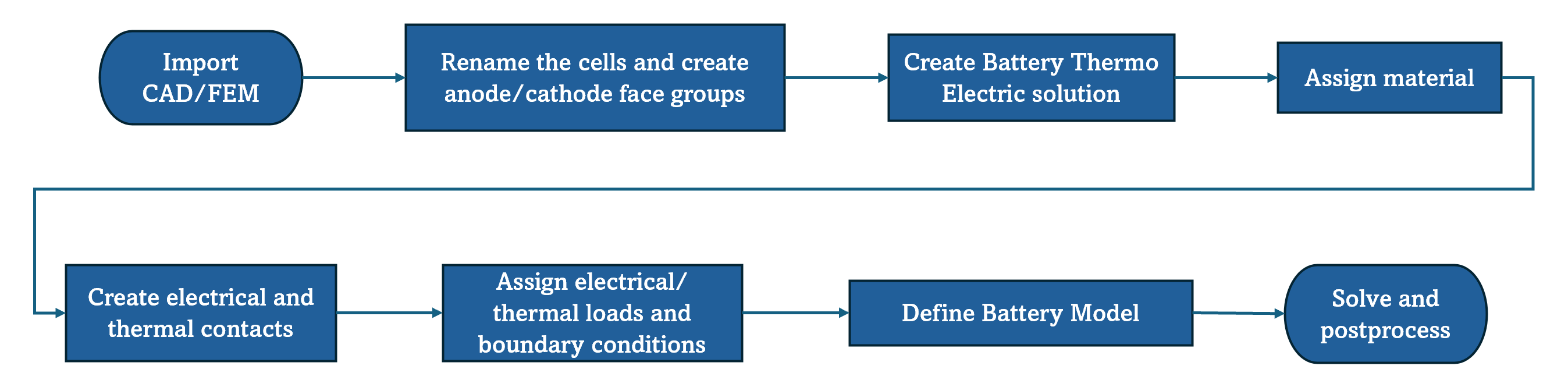

Workflow:

Following flow chart depicts the worflow of the Battery Thermo Electric solution.

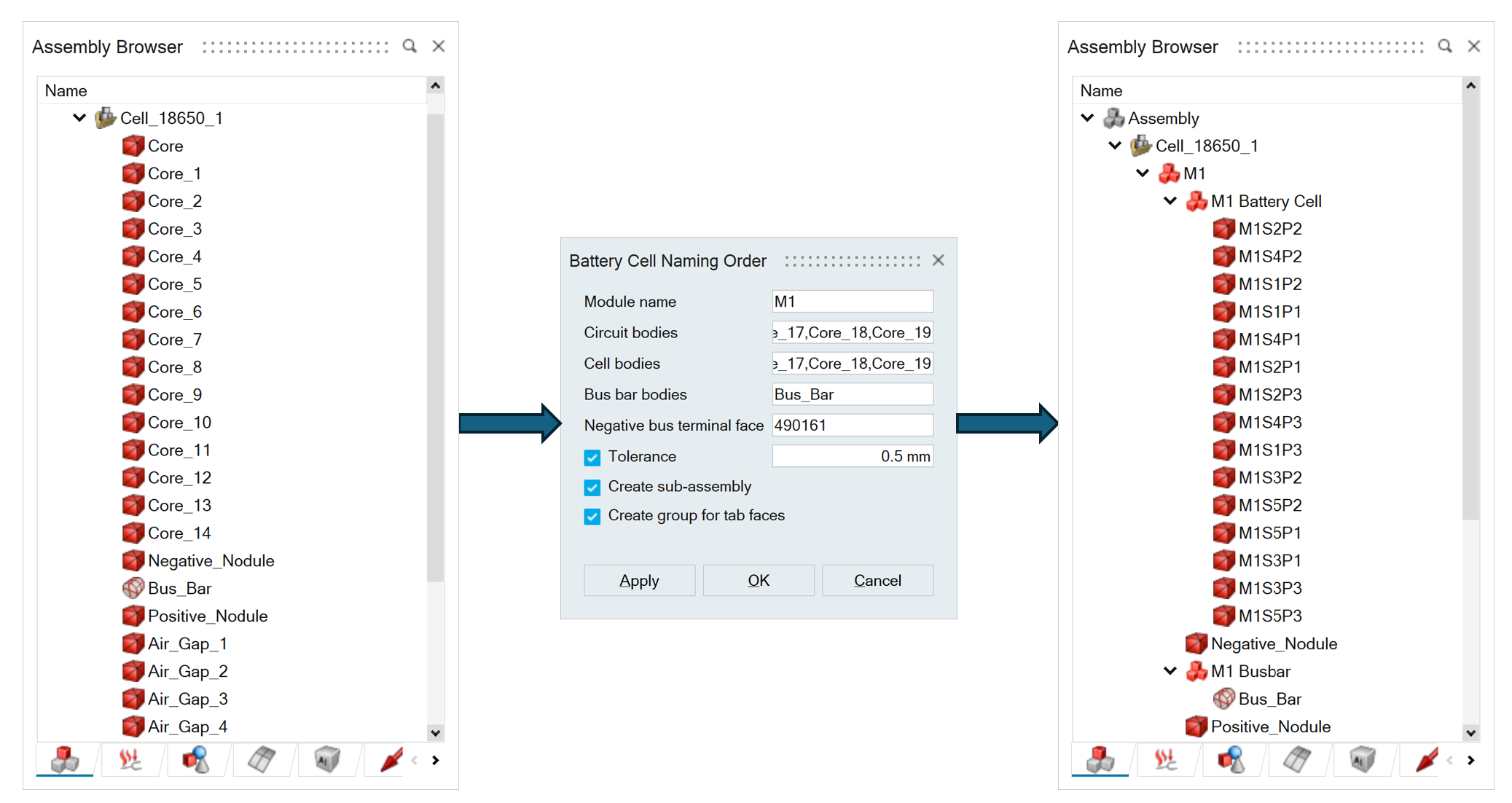

Rename jellyroll and create face groups:

Jellyroll should be named based on the series and parallel connectivity. This enables the solver to identify those bodies as jellyroll and build the circuit.

Cell naming tool:

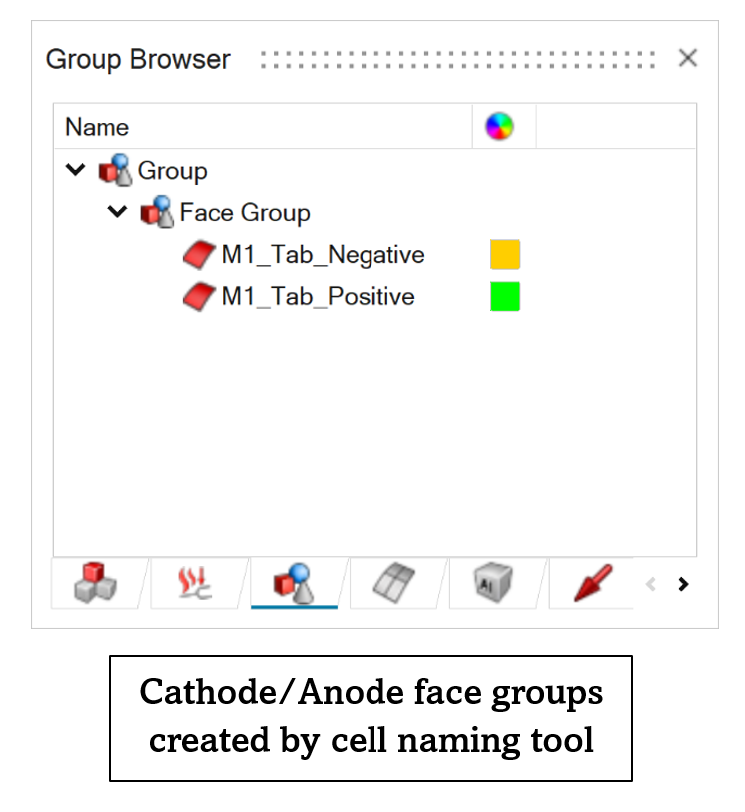

Use Cell naming tool to rename the jellyroll. The cell naming tool also creates face groups with cathode and anode faces of each cell.

- Face group, “M#_Tab_Positive” contains cathode faces from all the cells in a module. Likewise, “M#_Tab_Negative” face group contains anode faces from all the cell in a module.

- For each module in the battery pack, separate face groups are created.

- Face groups can also be created manually but the above naming convention should be followed.

- Ensure that the Anode/Cathode faces of each cell is added to the face groups.

- The 1D element (which represents the jellyroll in the electrical subcase) is created by connecting the cathode and anode faces of each cell.

- The cathode and anode faces corresponding to each cell is identified from the face groups created.

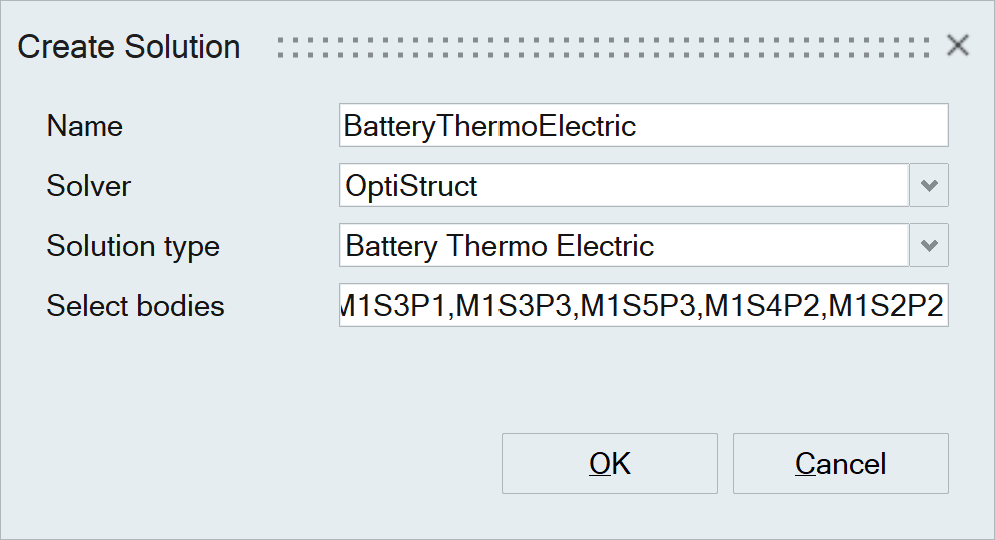

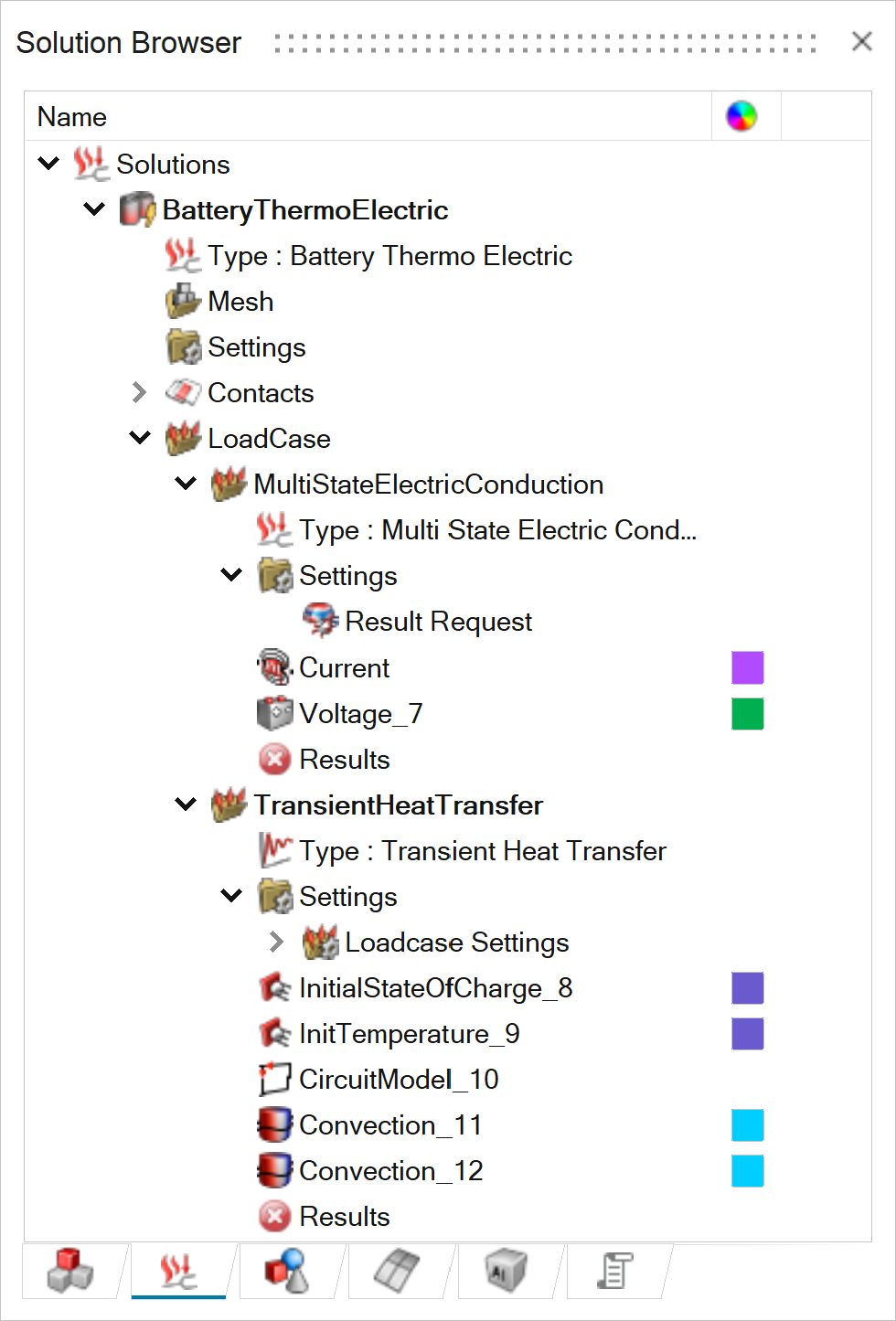

Thermo Electric Solution:

- Solution > Applications > Battery > Thermo Electric

- Solution will be created with two loadcases:

- (Loadcase 1) Multi State Electric Conduction: contains the electrical loads.

- (Loadcase 2) Transient Heat Transfer: contains the thermal loads and battery model.

- The solution supports both one-way and two-way coupling between electrical and thermal loadcases.

- Create and assign materials to the components with the electrical and thermal properties defined.

- Material definition supports Orthotropic input for thermal conductivity.

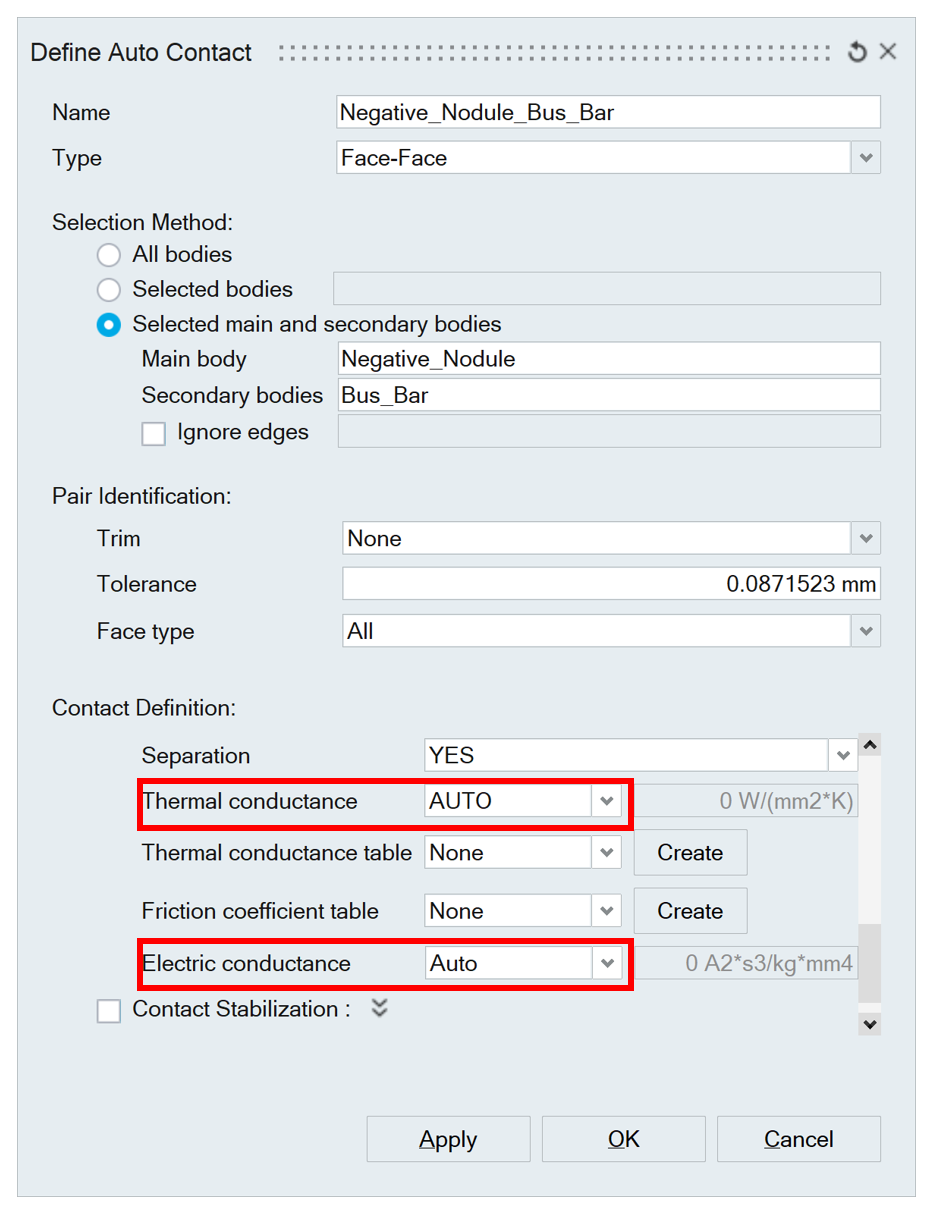

Contact creation:

- Use contact tool to define electrical/thermal connectivity between non-connected bodies.

- Use contact type “USE_CONTACT_PARAMS” to define electrical conductance and thermal conductance between circuit components.

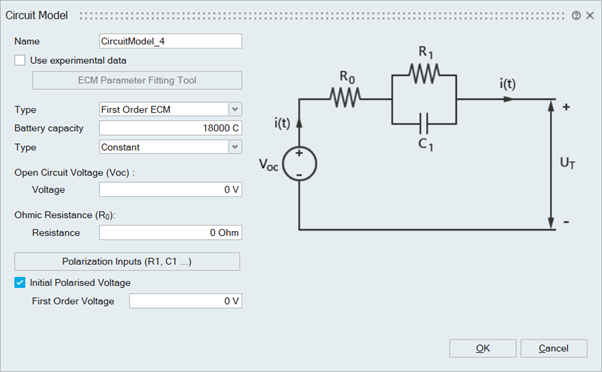

- Use Battery Model tool to define the Equivalent Circuit Model (ECM) parameters.

- 1st order and 2nd order ECM is supported.

- ECM parameters can be input as a constant or as a function of both SOC and temperature.

- Following are the parameters used in ECM to model the cells:

- Charging/Discharging current profile (i(t))

- Open circuit voltage (VOC)

- Internal cell resistance (R0)

- Polarized cell resistance (R1)

- Polarized cell capacitance (C1)

- Initial polarized voltage

Equivalent Circuit Model (ECM):

ECM represents the electro-chemical behaviour of a battery cell in terms of voltage, current, resistances, and capacitances. Jellyroll of each battery cell is modelled using an ECM.

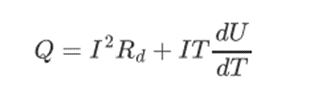

The above parameters of the ECM model are used in the Bernardi equation to calculate the ohmic heat generation (due to Joule heating effect) and entropic volumetric heat generation (due to exothermal electrochemical reaction in battery cells).

The heat generated in the jellyroll of a battery cell is given by:

dU/dT, corresponds to the variation of the open circuit voltage with respect to temperature.

Define battery modules

Modules can be defined using Battery Module in the analysis section.

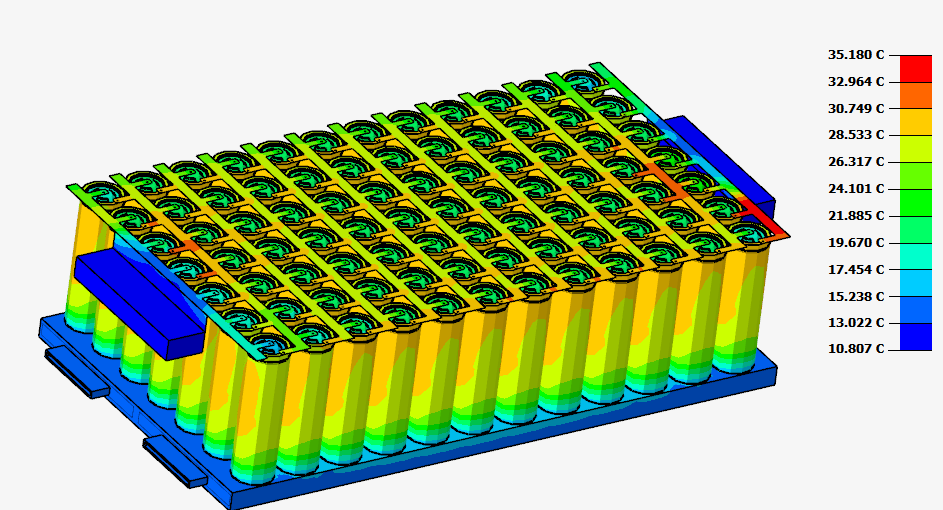

Postprocessing:

- The temperature distribution in the battery pack.

- Current density, electric potential and Joule loss density.

- Following cell level (BCELL) results are supported:

- Current flow

- Temperature (Max, Min and Avg)

- State Of Charge (SOC)

- Open circuit voltage

- Terminal voltage

Cards supported:

| Solver | Supported Cards |

|---|---|

| OptiStruct | BCELL, MCELL, PCELL, MODULE |