Joints

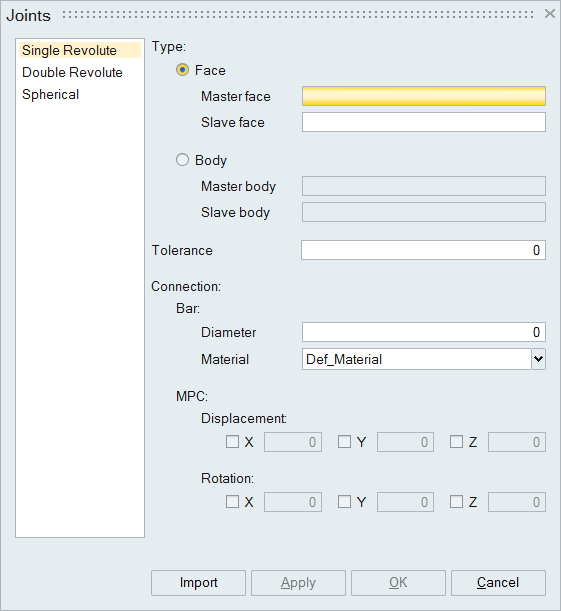

![]()

Description

The following joints can be modelled

- Single revolute joint

- Double revolute joint

- Spherical joint

- Planar/Cylindrical glue joint

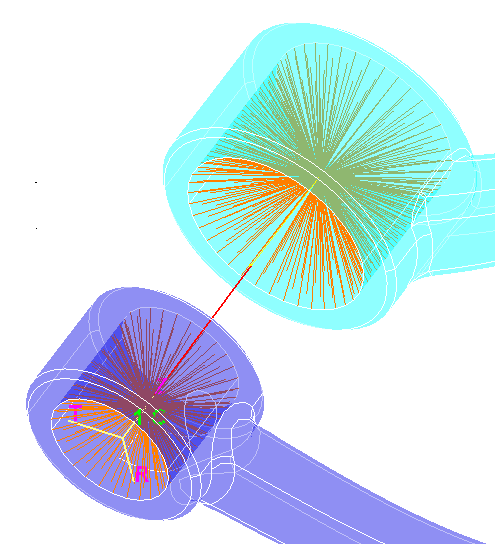

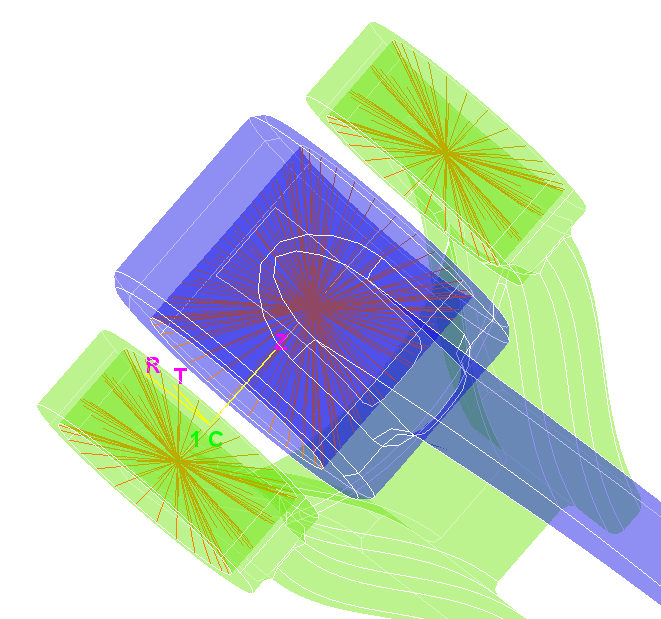

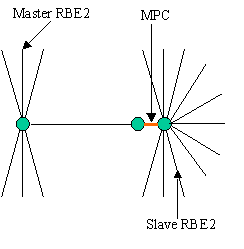

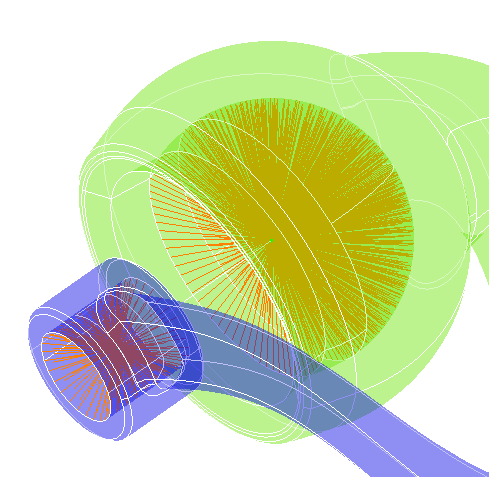

Joints can be modelled by selecting one face each from both master and slave body ("Face Based") or by directly selecting master and slave body ("Body Based"). Face from cylindrical faces of joint is to be selected for Face Based option. All other connected cylindrical faces will be identified automatically to model the joint. Body Based option will identify the matching coaxial cylinders and create joints. Revolute joints and spherical joints are modelled by creating master and slave RBE2 connected through bar and MPC.

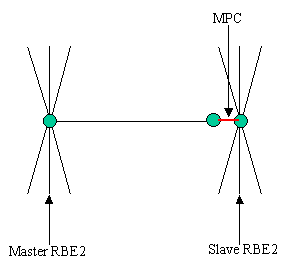

Single revolute joint

Center node of master RBE2 of single revolute joint is connected to the bar and other end of bar is connected to center node of slave RBE2 through MPC with respect to local coordinate system having z axis through the axis of joint.

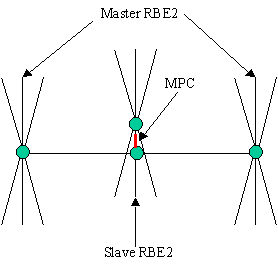

Double revolute joint

Center nodes of master RBE2 will be connected by 2 bar elements and the master node of slave RBE2 will be connected to the bar through MPC with local coordinate system having z axis through the axis of joint.

Spherical joint

Center node of master RBE2 of spherical joint is connected to the bar and other end of bar is connected to center node of slave RBE2 through MPC with respect to global coordinate system. The physical position of the center node of slave RBE2 is to be defined by the user. Selecting slave face is only to identify the slave body, therefore user can select any from slave body.

Joints can be imported directly from file by defining the body name and type ot joint. The keyword JOINT followed by other parameter define one joint.

Keywords to define joint

JOINT - Type of joint

MASTER - Name of master body

SLAVE - Name of slave body

TYPE - Type for MPC joint

ELEMENT_TYPE - Type of element for MPC joint

AXIS - Reference axis for MPC for MPC Joint

JOINT_FACES - Type of face of joint for MPC joint

FRICTION - Value for friction

TOLERANCE - Tolerance to identify matching faces for MPC Joint

DISPX - X displacement degrees of freedom for MPC

DISPY - Y displacement degrees of freedom for MPC

DISPZ - Z displacement degrees of freedom for MPC

ROTX - X rotation degrees of freedom for MPC

ROTY - Y rotation degrees of freedom for MPC

ROTZ - Z rotation degrees of freedom for MPC

RADIUS - Radius of bar

CENTERX - X abscissa for master node of slave RBE2 of spherical joint

CENTERY - Y abscissa for master node of slave RBE2 of spherical joint

CENTERZ - Z abscissa for master node of slave RBE2 of spherical joint

MATERIAL - Name of material for bar body

List of arguments to define each keywords for joints

JOINT = MPCGLUE_JOINT/SINGLE_REVOLUTE/DOUBLE_REVOLUTE/SPHERICAL

MPCGLUE_JOINT - MPC joint

SINGLE_REVOLUTE - Single revolute joint

DOUBLE_REVOLUTE - Double revolute joint

SPHERICAL - Spherical joint

TYPE = GLUE/SLIDER/GAP

ELEMENT_TYPE = RBE2/RBE3

JOINT_FACES = planar/Cylindrical/All

planar - Planar contact faces will be considered for MPC joint

Cylindrical - Cylindrical contact faces will be considered for MPC joint

All - Both cylindrical and planar faces will be considered for MPC joint

Sample File Definition

#Line starts with # is comment line

JOINT = MPCGLUE_JOINT

MASTER = Case

SLAVE = Bearing

TYPE = glue

ELEMENT_TYPE = rbe3

AXIS = GLOBAL

JOINT_FACES = all

FRICTION = 0.

TOLERANCE = 0.1

DISPX = 0

DISPY = 0

DISPZ = 0

ROTX =

ROTY =

ROTZ =

#****************************************

JOINT = SINGLE_REVOLUTE

MASTER = Case

SLAVE = Lever

MATERIAL = steel

DISPX = 0

DISPY = 0

DISPZ = 0

ROTX =

ROTY =

ROTZ =

TOLERANCE = 2

#****************************************

JOINT = DOUBLE_REVOLUTE

MASTER = Case

SLAVE = Lever

MATERIAL = steel

DISPX = 0

DISPY = 0

DISPZ = 0

ROTX =

ROTY =

ROTZ =

TOLERANCE = 2

#*****************************************

JOINT = SPHERICAL

MASTER = Case

SLAVE = Lever

MATERIAL = steel

CENTERX = 0

CENTERY = 0

CENTERZ = 0

RADIUS =

ROTY =

ROTZ =