RD-E: 2203 Ditching Multi-Domain

The Multi-Domain method is applied to ALE and SPH Fluid-Structure Interaction (FSI) ditching problems to demonstrate the computational speedup, accuracy, and ease of use.

Options and Keywords Used

Input Files

Model Description

Unit: mm, ms, KN, GPa, kg

The Multi-Domain method is used to optimize the computing performance of large Radioss models that can be sub-divided into distinct subdomains with clearly defined interfaces/connections between them and those different subdomains should be characterized by different mesh sizes and consequently very different minimum time step. The RD-E: 2201 ALE and RD-E: 2202 SPH ditching models are used to demonstrate a multi-domain setup. To make a larger time step difference between the Lagrangian impacting prism object and the fluid, the prism rigid body was updated so only the top edge of the prism is rigid and the rest of the prism is deformable. This results in a lower time step for the Lagrangian structure.

Model Method of Multi-Domain (Single Input Format)

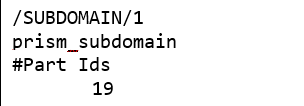

- In the Starter, use /SUBDOMAIN to define a sub-domain. In this example, part ID 19 is defined as a sub-domain.

Figure 1.Note: The subdomain_title “prism_subdomain” is the prefix used in the sub-domain Engine name prism_subdomain_0001.rad.

Figure 2. Domain Description in Multi-Domain Approach - Setup the two Engine files:

- First Engine file (main-domain):

- Using the Engine file from the Mono-Domain model add the /RAD2RAD/ON keyword.

- Second Engine file (sub-domain):

- Copy the Engine file from the Mono-Domain simulation and rename it, so the

prefix of the Engine file matches the title from the

/SUBDOMAIN Starter option.

In this example the sub-domain Engine is prism_subdomain_0001.rad.

- Add the /RAD2RAD/ON keyword.

- Update the run name in /RUN, so it matches the prefix of the sub-domain Engine file. /RUN/prism_subdomain/1.

- Define the Lagrange parts (part ID 19) time step control.

In this case, /DT/NODA is used.

- Copy the Engine file from the Mono-Domain simulation and rename it, so the

prefix of the Engine file matches the title from the

/SUBDOMAIN Starter option.

- First Engine file (main-domain):

Results

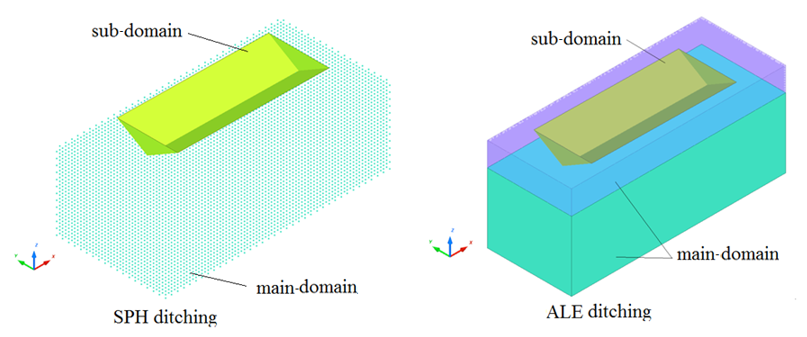

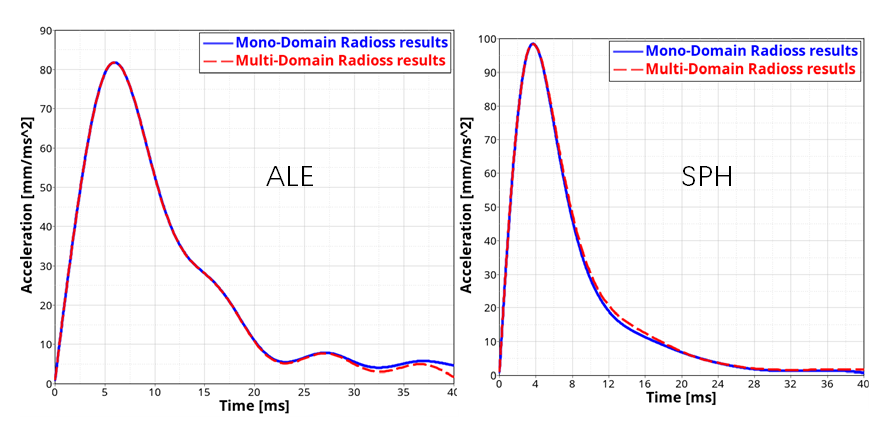

Since the Multi-Domain models used a prism that was deformable, the results cannot be directly compared to the results from RD-E: 2201 ALE and RD-E: 2202 SPH ditching models. Therefore, the Multi-Domain models were rerun as Mono-Domain to obtain results for the comparison.

Figure 3. Comparison between Mono-Domain and Multi-Domain

- Time step

Figure 4. Comparison between Mono-Domain and Multi-Domain

- Number of elements

- Number of cycles

- Element average time cost/cycle

- Relative element number:

(2) - Relative time step (relative cycle numbers):

(3) with being time step.

- Relative cost per cycle:

(4) - Lagrange shell

- = 1

- Lagrange solid

- ~ 3

- ALE solid

- ~ 6

- SPH cell

- ~ 15

Speedup will then be:(5) - Elapsed times:

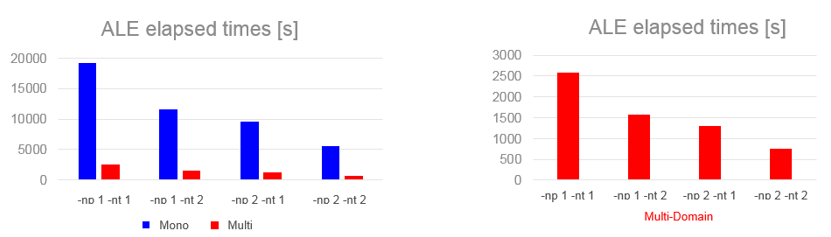

Figure 5. ALE Ditching

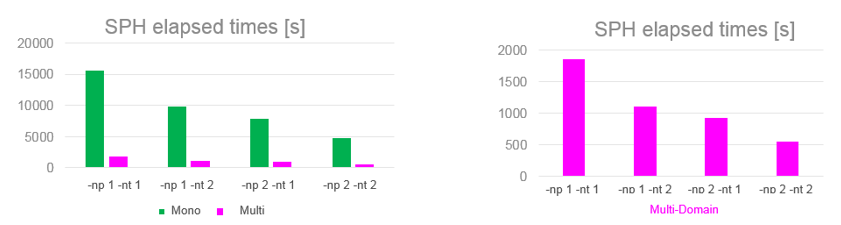

Figure 6. SPH Ditching

The Multi-Domain FSI speedup ranges from 6 times to 9 times of the Mono-Domain depending on the number of cores used in the simulation.

Conclusion

- For Multi-Domain with ALE or SPH, there is no need to minimize the contact interfaces between fluid and structure.

- For Multi-Domain FSI, it is advised to use have the fluid in the main domain and defined /DT/ALE with an elementary free time step with a scaling factor of 0.5 for ALE. In the Lagrange subdomain, a nodal time step /DT/NODA with a scaling factor of 0.9 should be used.

- When Lagrange parts are assembled using tied contact interface TYPE2 improved speed-up is obtained using Spotflag = 27 to switch from kinematic to penalty formulation to solve the problem.