RD-E: 2201 Ditching using ALE

Impact of a simple object on water simulated by the ALE approach.

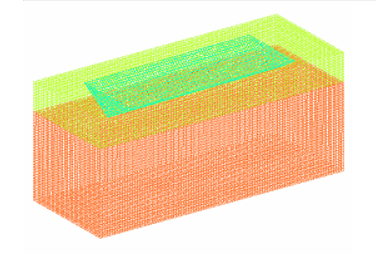

Figure 1.

The ditching of a prism object into a pool of water is studied using the Arbitrary Lagrangian-Eulerian (ALE) approach. The simulation results are compared to the experimental data and analytical results. Furthermore, the study is performed using two different impact velocities. The impacting structure is a triangular prism section. The water is modeled with an ALE mesh while the structure is Lagrangian. The fluid-structure contact interactions are modeled using a /INTER/TYPE18 interface.

Options and Keywords Used

- /MAT/LAW1 (ELAST)

- /MAT/LAW37 (BIPHAS)

- /MAT/LAW51 (MULTIMAT)

- /INTER/TYPE18

- EULER property formulation with Iale = 2

Input Files

Model Description

The problem consists of a simple object falling into water simulating the ditching of a helicopter.

Units: mm, ms, KN, GPa, kg

The impact of the triangular prism object on the water is performed and the results are compared qualitatively to analytical results from 2 and also using the experimental data obtained from the Politechnico di Milano. 1

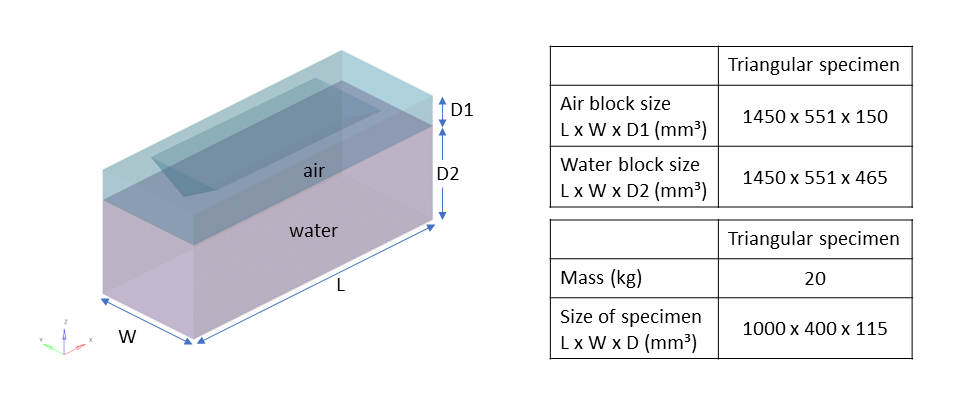

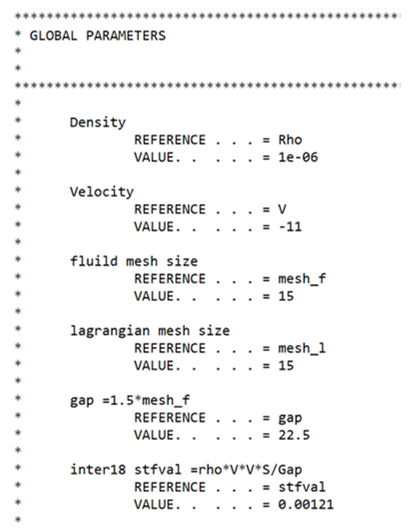

Figure 2. Problem data

The impacting prism is modeled using shell elements with an average mesh size of 15 mm x 15 mm. To shorten the computation, it is made rigid with an accelerometer on the main node of the rigid body.

The water is modeled using solid elements consisting of a 15x15x15 mm mesh. The solid element property, /PROP/ TYPE14 (SOLID) is used with Iale = 2 for EULER property formulation.

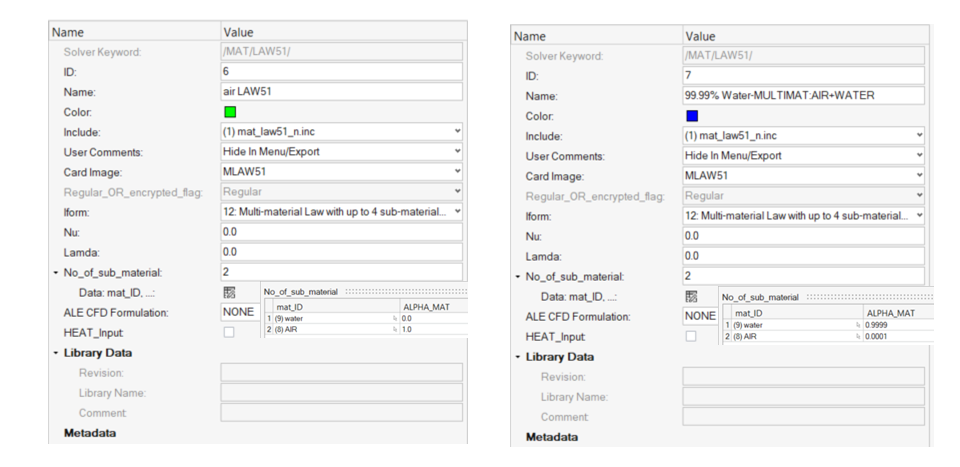

For modeling air and water /MAT/LAW51 is used utilizing several /MAT/LAW6 as sub-materials as it is the recommended best practice. The input file for the model using /MAT/LAW51 is included as an example.

- Initial density (Rho_initial) = 1.22e-09 (kg/m³)

- EoS_Options_Input (IDEAL_GAS)

- Heat Capacity Ration (Gamma) = 1.4

- Initial Pressure (P0) = 0.0001 (Pa)

- Initial Temperature (T0) = 300 (K)

- Initial density (Rho_initial) = 1.0 e-06 (kg/m³)

- EoS_Options_Input (STIFF_GAS)

- Heat Capacity Ration (Gamma) = 6.1

- Initial Pressure (P0) = 0.0001 (Pa)

- EoS Parameter (P_star) = 0.36885

Figure 3. /MAT/LAW51 material properties

In the multi-material LAW51, the amount of each sub-material is defined. To improve numerical stability, it is recommended to define the water as 99.99% water and 0.01% air.

Boundary Setup

An initial velocity and gravity are applied to the prism in the Z direction.

- X translation component fixed for lateral faces normal to X

- Y translation component fixed for lateral faces normal to Y

- Z translation component fixed for lower and upper faces

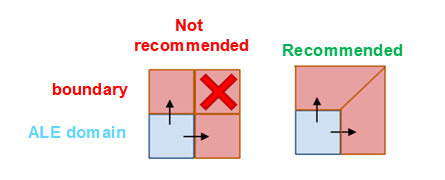

Figure 4. Boundary mesh treatment

Fluid Structure Interaction (FSI)

An /INTER/TYPE18 interface is defined to manage the contact between the Lagrangian mesh (Prism) and the ALE fluid. The impacting prism is the Lagrangian surface and the ALE fluid is the ALE brick elements group.

- The (highest) fluid density

- Estimated relative velocity of the phenomenon

- Average surface area of the Lagrangian elements

- Contact gap

The recommended Gap value is 1.5 times the average element length of the ALE mesh.

Figure 5.

Results

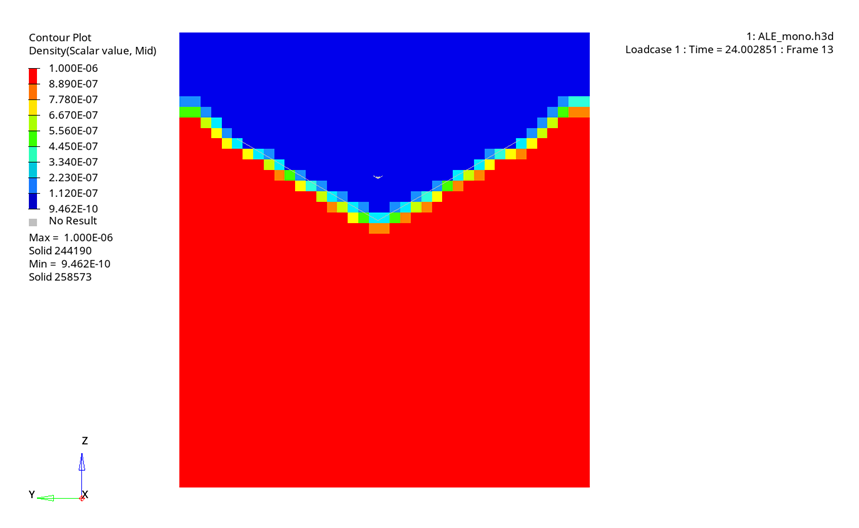

Figure 6. Density results for LAW51

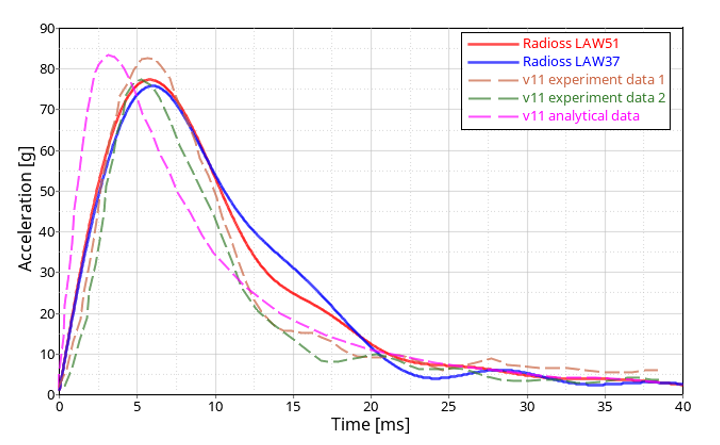

Figure 7. Acceleration results for 11 m/s for simulation, theoretical solution, and experimental test

The ALE method results in a maximum acceleration of 77.3 g for LAW51 and 75.8 g for LAW37. However, the Von Karman theoretical solution delivers 83.5 g. The maximum value from the test is between 82.8 g and 77.5 g.

In general, the ALE results match the analytical and experiment curve, especially at the duration for acceleration beyond 40 g. Using material LAW51 is recommended because it results in a more discrete boundary at the fluid-structure interface.