RD-E: 5600 Hyperelastic Material with Curve Input

The target of this example is to demonstrate how to use material test data for rubber hyperplastic materials.

Options and Keywords Used

- Ogden material law /MAT/LAW42 (OGDEN)

- /MAT/LAW62 (VISC_HYP)

- /MAT/LAW69

- /MAT/LAW82

- /MAT/LAW88

- Arruda-Boyce material law /MAT/LAW92

- Yeoh material law /MAT/LAW94 (YEOH)

Input Files

Model Description

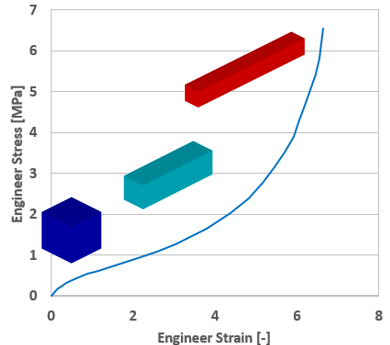

Uniaxial tensile one brick element with imposed displacement and fixed in other side only in X direction.

Units: mm, s, Mg, N, MPa

Table 1 shows curve input or parameter input available for hyperelastic material model.

Properties: /PROP/SOLID with, Isolid=24, Ismstr=10, and Icpre=1.

When using hyperelastic material laws, there are some recommended element property settings. When using solid elements, it is always better to mesh with 8 node /BRICK elements if possible. If not then /TETRA4 or /TETRA10 elements can be used.

- Ismstr=10

- Icpre=1 with Isolid=24.

Simulation Iterations

| Material Law | Test Data Input | Parameter Input | |

|---|---|---|---|

| Ogden | LAW42 | √ | |

| LAW62 | √ | ||

| LAW69 | √ | ||

| LAW82 | √ | ||

| LAW88 | √ | ||

| Arruda-Boyce | LAW92 | √ | √ |

| Yeoh | LAW94 | √ |

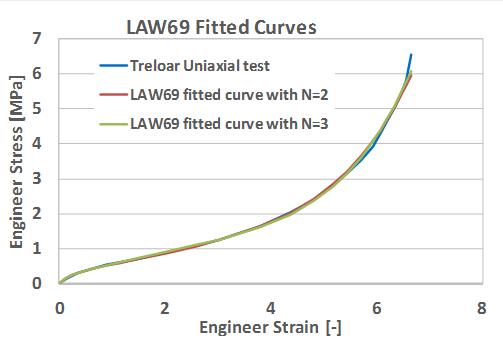

For the Ogden based laws, LAW69 will be used to curve fit the test data and extract material parameters that can be used in LAW42, LAW62, and LAW82. Next the test data will be used in LAW88 and LAW92. Finally, a fitting script will be used to extract the LAW94 material parameters.

Results

Ogden Model

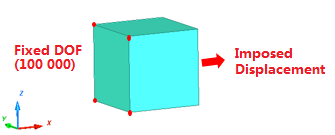

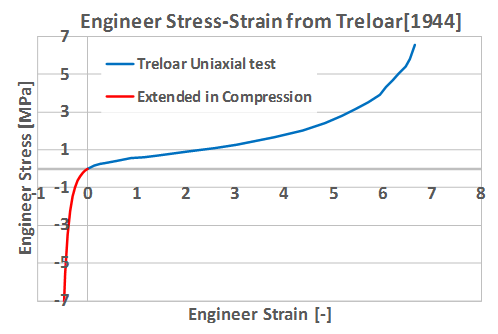

Material LAW69 can define a hyperelastic and incompressible material which uses the Ogden, or Mooney-Rivlin material models. It is generally used to model incompressible rubbers, polymers, foams, and elastomers. Material parameters for the Ogden or Mooney-Rivlin material models are computed from the engineering stress-strain curve from uniaxial tension (positive strain) and compression (negative strain) tests. The uniaxial data from Treloar is tension only. However, for incompressible materials, uniaxial compressive data can be calculated from the equal biaxial tension test data using these formulas from 3.

- Uniaxial engineering compressive stain

- Equal biaxial engineering tension strain

- Uniaxial engineering compressive stress

- Equal biaxial engineering tension stress

The engineering strain should be monotonically increasing going from a negative value in compression to a positive value in tension. In compression, the engineering strain should not be less than -1.0 since -100% strain is physically not possible. Fitting test data that represents the anticipated strain state of material will give the most accurate material parameters for a particular situation. Although a tension only uniaxial stress strain curve could be used, this example uses uniaxial compression and tension data to better fit for both compressive and tension loading conditions.

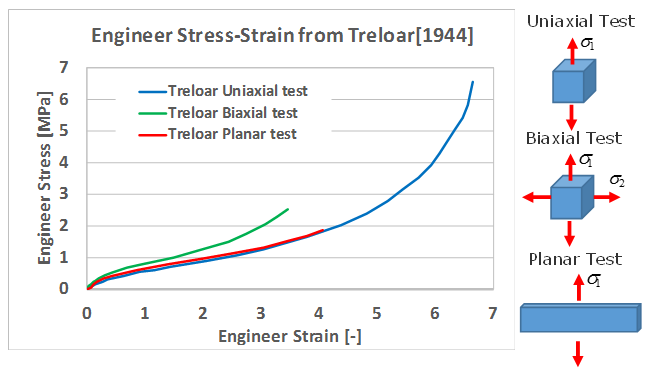

- Number of material parameter ( ) pairs: N=2 or 3. (N > 3 is rarely used)

- Engineering stress-strain curve from uniaxial compression/tension test set in fct_ID1

- : This value is to get the best fit for the incompressible rubber material but as described later, this high value causes a low time step and thus a value of 0.495 is typically recommended.

After running the Radioss Starter, the output file (*0000.out) contains the stress strain curve for the calculated material fit parameters and the original input data. The calculated fitted parameters, shear modulus, and bulk modulus are also included in the output.

FITTING RESULT COMPARISON:

UNIAXIAL TEST DATA

NOMINAL STRAIN NOMINAL STRESS(TEST) NOMINAL STRESS(RADIOSS)

-0.9495 -221.4526 -220.7771

-0.9449 -176.9213 -175.8148

-0.9396 -138.1769 -139.3528

-0.9289 -93.5350 -93.1405

-0.9150 -60.3881 -61.2494

-0.8911 -35.8292 -35.2551

-0.8387 -15.4000 -15.5512

-0.7343 -5.7900 -5.7761

-0.6457 -3.1912 -3.2391

-0.5041 -1.5128 -1.5510

-0.4173 -1.0147 -1.0297

-0.3056 -0.5855 -0.5989

....... ....... ........

-------------------------------------------

AVERAGED ERROR OF FITTING : 2.00%

FITTED PARAMETERS FOR HYPERELASTIC_MATERIAL LAW

----------------------------------------

OGDEN LAW PARAMETERS:

MU1 . . . . . . . . . . . . . . . . . .=-0.2397367723469

MU2 . . . . . . . . . . . . . . . . . .= -11.57584346215

MU3 . . . . . . . . . . . . . . . . . .= 11.57477242242

MU4 . . . . . . . . . . . . . . . . . .= 0.000000000000

MU5 . . . . . . . . . . . . . . . . . .= 0.000000000000

AL1 . . . . . . . . . . . . . . . . . .= -4.548308811208

AL2 . . . . . . . . . . . . . . . . . .= 5.714056272418

AL3 . . . . . . . . . . . . . . . . . .= 5.714110104590

AL4 . . . . . . . . . . . . . . . . . .= 0.000000000000

AL5 . . . . . . . . . . . . . . . . . .= 0.000000000000

GROUND-STATE SHEAR MODULE . . . . . . .= 0.5424499939537

BULK MODULUS. . . . . . . . . . . . . .= 903.9025065914

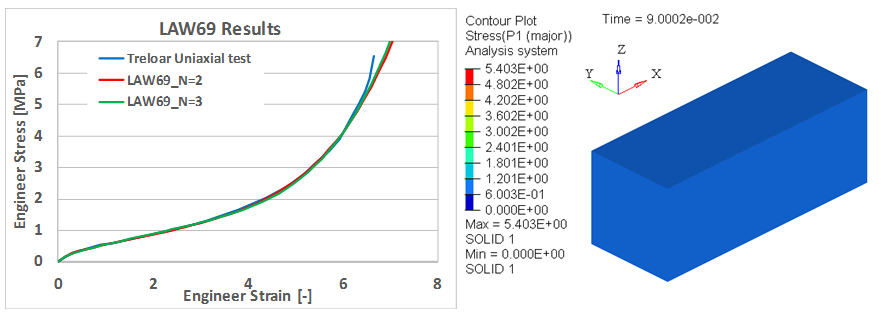

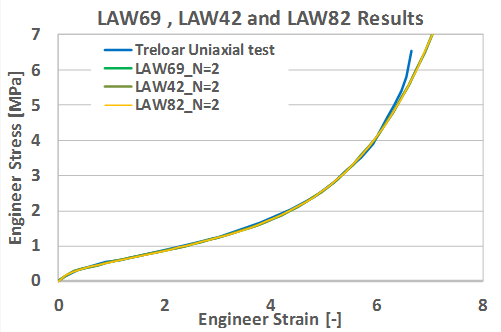

Figure 5 shows the calculated stress strain curve from the 1 element model simulation matches the Treloar test data.

The engineering stress strain curves were calculated from the true stress and true strain in principal direction 1 (P1) from the animation output /ANIM/BRICK/TENS/STRAIN and /ANIM/BRICK/TENS/STRESS using these formulas.

,

,

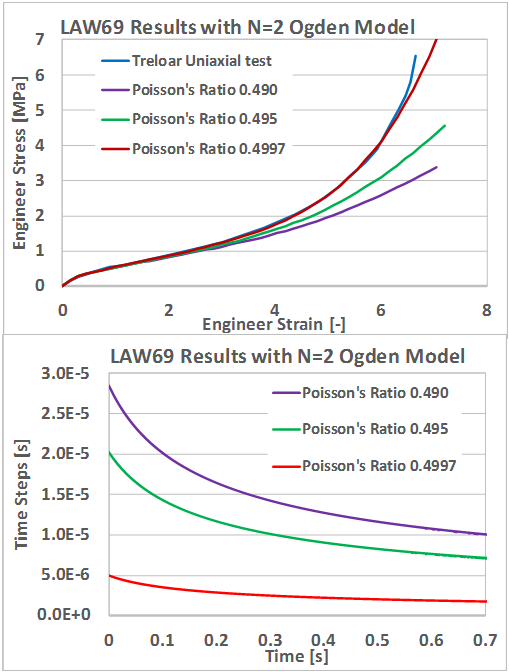

In LAW69, the fitted Ogden parameters are based on assumption of incompressible material which means that . However, in practice is not possible to use because that would result in an infinite bulk modulus, an infinite speed of sound, and thus, an infinitely small solid element Time Step.

The effect of different Poison’s ratio input can be seen in Figure 6. The largest difference in the results is at higher amounts of strain. The results will match the test data better when but this results in a time step that is 4 times lower than . Thus, to balance the computation time and accuracy it is recommended to use for incompressible rubber material.

- For LAW42, the LAW69 fitted Ogden parameters can be taken from the

Starter output and used as input in LAW42.

LAW42

- For LAW62 and LAW82, the Ogden parameters need to be converted from

LAW69 fitted Ogden parameters because the Ogden model equation is

different in LAW62 and LAW82.

Considering an Ogden model with N=2, the energy density function used in LAW42 and LAW82 are shown here for an incompressible material.

LAW62 (and LAW82)

- LAW62

- LAW82

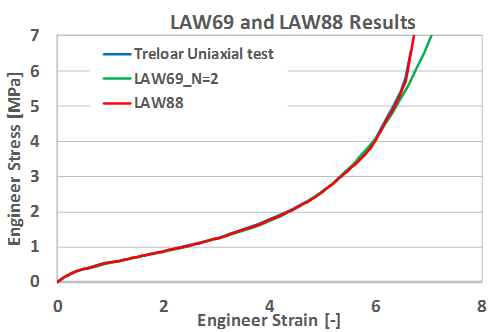

Figure 9 shows the material fit parameters from LAW69 converted into LAW82 match the LAW69 and LAW42 results for Ogden order, N=2.

#RADIOSS STARTER

/UNIT/1

UNIT FOR MAT

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/OGDEN/1/1

rubber LAW42

# RHO_I

1E-9

# Nu sigma_cut funIDbulk Fscale_bulk M Iform

.4997 0 0 0 0 0

# Mu_1 Mu_2 Mu_3 Mu_4 Mu_5

1.2732565785698E-05 -0.2635330119696 0 0 0

# blank card

# alpha_1 alpha_2 alpha_3 alpha_4 alpha_5

7.168617832124 -4.158214786551 0 0 0

# blank card

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW82/1

rubber LAW82

# RHO_I

1E-9 0

# N Nu

2 .4997

# Mu_i

0.000045637449070023 0.547913433558156 0 0 0

# Alpha_i

7.168617832124 -4.158214786551 0 0 0

# D_i

0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

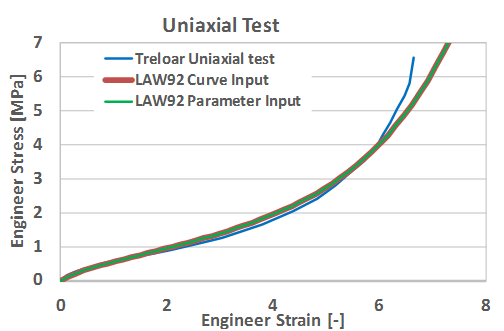

Arruda-Boyce Model

In LAW92, if the curve input is used then the parameter lines can be left blank. Only one type of test data type can be considered at a time.

#RADIOSS STARTER

#- 2. MATERIALS:

/UNIT/1

UNIT FOR MAT

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW92/1/1

rubber

# RHO_I

1.000E-9

# mu D LAM

0 0 0

# IType fct_ID NU

1 3 .4997

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|-------------------------------------------

AVERAGED ERROR OF FITTING : 12.72%

FITTED PARAMETERS FOR HYPERELASTIC_MATERIAL LAW

----------------------------------------

ARRUDA-BOYCE LAW

MU . . . . . . . . . . . . . . . . . . . .= 0.3023683957840

D. . . . . . . . . . . . . . . . . . . . .= 3.8695518555789E-03

LAM. . . . . . . . . . . . . . . . . . . .= 4.917777266862

GROUND-STATE SHEAR MODULE. . . . . . . . .= 0.3101754654817

BULK MODULUS . . . . . . . . . . . . . . .= 516.8557173143When the Radioss Engine is ran, the fitted Arruda-Boyce parameters are used to compute the stress-strain behavior in hyperelastic material. Therefore, if the above fitted Arruda-Boyce parameter are used as LAW92 input, the results will be the same.

#RADIOSS STARTER

#- 2. MATERIALS:

/UNIT/1

UNIT FOR MAT

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW92/1/1

rubber

# RHO_I

1.000E-9

# mu D LAM

0.3023683957840 3.8695518555789E-03 4.917777266862

# IType fct_ID NU

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

- Fitted in LAW92 Curve Input

- 6.4695283364675E-02

- 3.8695518555789E-03

Only one test type (Itype) can be used in LAW92. Different Arruda-Boyce parameters are calculated for each different type of test data. If uniaxial test type is used in LAW92, it would describe the uniaxial deformation behavior better than biaxial or shear behavior. In order to better describe all the possible deformation behavior, an engineer can set proper weights for each from three different test types.

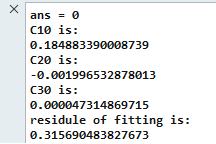

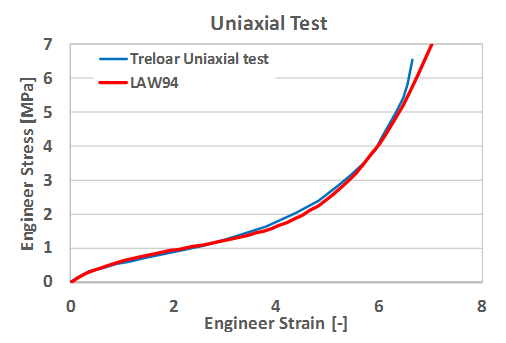

Yeoh Model

The fitting script assumes an incompressible ( ) hyperelastic material. The strain energy density of Yeoh then becomes:

Since the Yeoh model only depends on , only the uniaxial test is needed to calculate the Yeoh material parameters. Here are the stretch in principal direction 1, 2, 3 and . is the engineer strain in principal direction .

Uniaxial Test

and

Then with and you get , as:

And the Cauchy stress of Yeoh model is computed as:

In uniaxial test the Cauchy stress in principal direction 1 is:

Next, the curve fit values can be used in LAW94 and the results compared to the original test data. In the example, you have been using to get a good fit to the test data. can then be calculated from .

Where, .

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW94/1

plastic

# RHO_I

1.0E-9

#Blank

# C10 C20 C30

0.184883390008739 -0.001996532878013 0.000047314869715

# D1 D2 D3

0.003245938015181

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

References

http://www.axelproducts.com/downloads/TestingForHyperelastic.pdf