/MAT/LAW88

Block Format Keyword This law represents the behavior of a hyperelastic material with strain rate effects. This law is generally used to model incompressible rubbers, polymers, foams, and elastomers. It is defined by a family of stress versus strain curves at different strain rates.

Unloading can be represented using an unloading function or by providing hysteresis and shape factor inputs to a damage model based on energy. This law is only compatible with solid elements.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW88/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| K | Fcut | Fsmooth | NL | ||||||

| fct_IDunL | FscaleunL | Hys | Shape | Tension | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_IDLi | FscaleLi | ||||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| Poisson ratio. For incompressible materials 0.495 is maximum value. Default = 0.495 (Real) |

||

| K | Bulk modulus. (Real) |

|

| Fcut | Cutoff frequency for strain rate

filtering. Default = 1030 (Real) |

|

| Fsmooth | Smooth strain rate option flag.

(Integer) |

|

| NL | Number of loading stress strain

curve. (Integer) |

|

| fctunL | Unloading engineering stress versus

engineering strain function identifier. 3 (Integer) |

|

| FscaleunL | Unloading function scale

factor. Default = 1.0 (Real) |

|

| Hys | Hysteresis unloading factor. Ignore if,

unloading function is used. 3 0.0 ≤ Hys ≤ 1.0 Default = 0.0 (Real) |

|

| Shape | Shape factor. Ignored if, unloading

function is used. 3 Default = 1.0 (Real) |

|

| Tension | Unloading rate effects option flag.

4

Otherwise, the quasi-static loading curve is used for unloading. (Integer) |

|

| fct_IDLi | Loading function identifier defining

engineering stress versus engineering strain for ith strain rate

function. (Integer) |

|

| Strain rate for ith loading

engineering stress versus engineering strain function. (Real) |

||

| FscaleLi | Scale factor for ith loading

function. Default = 1.0 (Real) |

Example (Rubber)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW88/1/1

rubber

# RHO_I

1E-6

# NU K F_cut F_smooth N_L

.495 19.93 0 1

#fctID_Unl Fscale_unload HYs Shape Tension

1 1. 0. 0. 0

#fctID_l Fscale_load Eps_._load

1 1. 0.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/1

function 1

# X Y

-8.51E-01 -3.55E+01

-7.76E-01 -1.10E+01

-7.02E-01 -4.83E+00

-6.01E-01 -2.06E+00

-5.00E-01 -1.05E+00

-4.05E-01 -5.98E-01

-3.04E-01 -3.33E-01

0.00E+00 0.00E+00

4.05E-01 1.53E-01

8.50E-01 2.37E-01

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- This model utilizes an Ogden material formulation. Material parameters are directly derived from the input stress strain curves from uniaxial tests for different strain rates. The material is assumed to be nearly incompressible with Poisson’s ratio = 0.495.

- Strain rate effects can be modeled by

including loading engineering stress strain test data at different strain rates

fct_IDLi. This can be easier than

calculating viscous parameters for traditional hyperelastic material models. When using

stress strain curves at different strain rates, the following suggestions are

recommended:

- The stress strain curve should be monotonic increasing and smooth. The derivative of the stress strain curve should be smooth.

- Enable strain rate smoothing by defining, Fsmooth =1 with Fcut =500 Hz.

- Unloading can be represented using an unloading

function, FscaleunL, or by providing

hysteresis, Hys,

and shape factor, Shape,

inputs to a damage model based on energy.

- The unloading behavior does not consider the strain rate dependency.

- Unloading hysteresis stress is computed from the quasi-static behavior

with:

(1) with(2)

Where,- Current energy

- Maximum energy corresponding to the quasi-static behavior

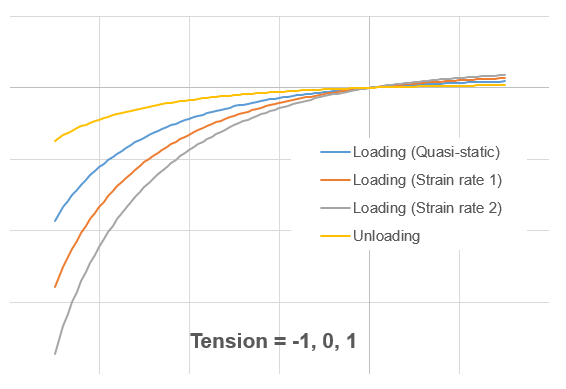

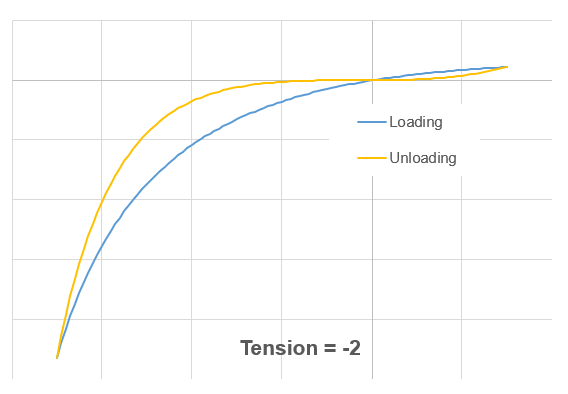

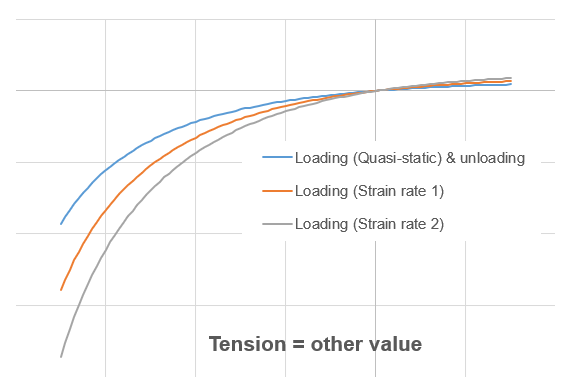

- The loading and unloading curves are

defined with positive stress and strain in tensile and negative stress and strain in

compression.The following curves are needed according to Tension flag:

- Tension = -1, 0, or

1

Figure 1. - Tension = -2

Figure 2. - Tension = other value

Figure 3.

- Tension = -1, 0, or

1

- /VISC/PRONY can be used with this material law to include viscous effects.