/MAT/LAW33 (FOAM_PLAS)

Block Format Keyword This law models a viscous-elastic foam material with unloading/reloading like plastic behavior. This law is applicable only for solid elements and is typically used to model low density, closed cell polyurethane foams such as impact limiters.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW33/mat_ID/unit_ID or /MAT/FOAM_PLAS/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | Ka | fct_IDf | Fscalecrv | ||||||

| P0 | |||||||||

| A | B | C | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| E1 | E2 | Et | |||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E | Young's modulus. (Real) |

|

| Ka | Analysis type flag.

(Integer) |

|

| fct_IDf | Yield stress versus volumetric strain curve

function identifier. (Integer) |

|

| Fscalecrv | Scale factor for ordinate (stress) for

fct_IDf. Default = 1.0 (Real) |

|

| P0 | Initial air pressure. 5

(Real) |

|

| Ratio of foam to polymer

density. (Real) |

||

| Initial volumetric strain. (Real) |

||

| A | Yield parameter. (Real) |

|

| B | Yield parameter. (Real) |

|

| C | Yield parameter. (Real) |

|

| Tension stress cutoff (used only with

Ka

=2). Default = 120 (Real) |

||

| E1 | Coefficient for Young's modulus

update. (Real) |

|

| E2 | Coefficient for Young's modulus

update. (Real) |

|

| Et | Tangent modulus. (Real) |

|

| Viscosity coefficient in pure

compression. (Real) |

||

| Viscosity coefficient in pure

shear. (Real) |

Example (Foam)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/FOAM_PLAS/1/1

Foam

# RHO_I

2E-10

# E Ka func_IDf Fscalecurv

200 1 0 1

# P0 Phi Gamma_0

0 0 0

# A B C SIG_COFF

1E30 0 0 0

# E1 E2 Et eta_comp eta_shear

0 0 2 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- If the limiting yield curve is not

defined, then the material follows a

Maxwell-Kelvin-Voight visco-elastic model.

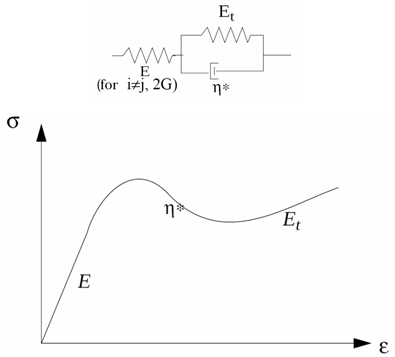

Figure 1. - If the limiting yield curve is defined, then the material initially follows the visco-elastic law until it intersects the defined yield curve, which limits the visco-elastic stress in tension and compression. The material does not experience plasticity, but instead behaves in a visco hyperelastic way.

- If the yield function

fct_IDf

= 0, then

(1) Where, is the volumetric strain:(2) - If the yield function

fct_IDf

≠ 0, then

versus

is read from input of the

curve identifier

fct_IDf.

The curve can be defined for tensile (

) and compression (

). The input stress

should be positive for both tension and

compression.

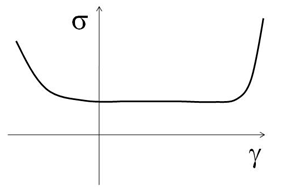

Figure 2. - The optional air pressure, as a

function of the volumetric strain can be added to

the structural pressure. Pressure is applied only

on the spherical part of the stress

tensor.

(3) - Young’s modulus is used as the initial

slope for unloading. It can be constant or

variable, based on the strain

rate.

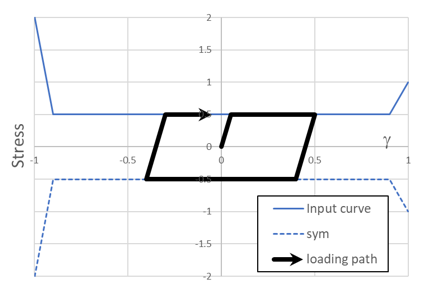

(4) - The unloading or the loading direction

change (tensile <-> compression) is following

the current elastic modulus, like an isotropic

elastic-plastic material or highly viscous foam

material. However, there is no plastic strain

accumulation.

Figure 3.